Platinum-loaded nitrogen phosphorus co-doped carbon material hydrogen evolution catalyst, preparation method and application thereof

A technology of co-doping and carbon materials, applied in the direction of electrical components, battery electrodes, circuits, etc., to achieve the effects of easy operation, excellent electrocatalytic activity and stability, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] One aspect of the embodiments of the present invention provides a method for preparing a platinum-supported nitrogen-phosphorus co-doped carbon material hydrogen evolution catalyst, which includes:

[0019] Calcining nitrogen-containing polymers mainly formed by the reaction of phosphorus-containing precursors and nitrogen-containing polymer monomers at high temperatures in a protective atmosphere to obtain carbon materials co-doped with nitrogen and phosphorus;

[0020] The nitrogen and phosphorus co-doped carbon material is uniformly mixed with a platinum source in a solvent, and a reducing agent is added to prepare a platinum-supported nitrogen and phosphorus co-doped carbon material hydrogen evolution catalyst.

[0021] In some preferred embodiments, the preparation method includes: quickly mixing the phosphorus-containing precursor, the nitrogen-containing polymer monomer and the initiator in a solvent at a temperature of 0-4°C, and mixing the mixed liquid Stand ov...

Embodiment 1

[0044] (1) Preparation of nitrogen and phosphorus co-doped carbon materials

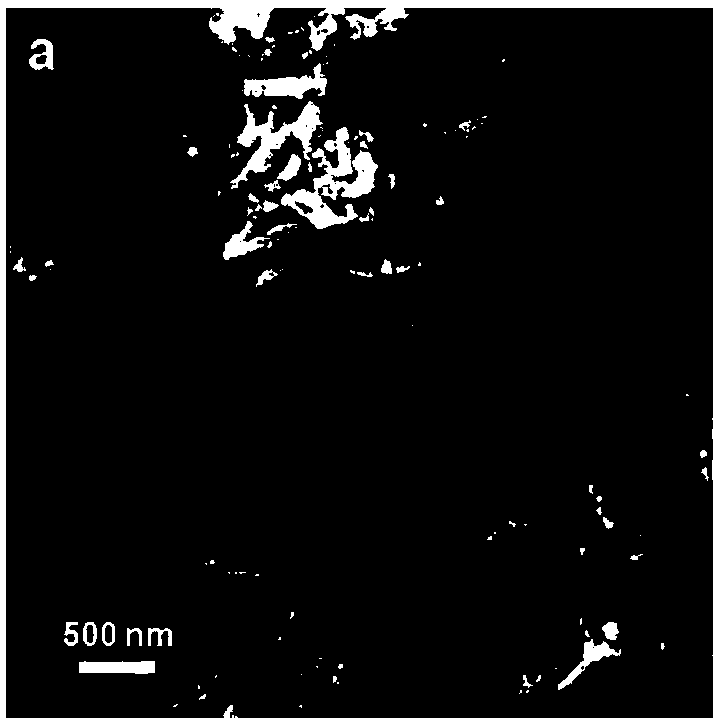

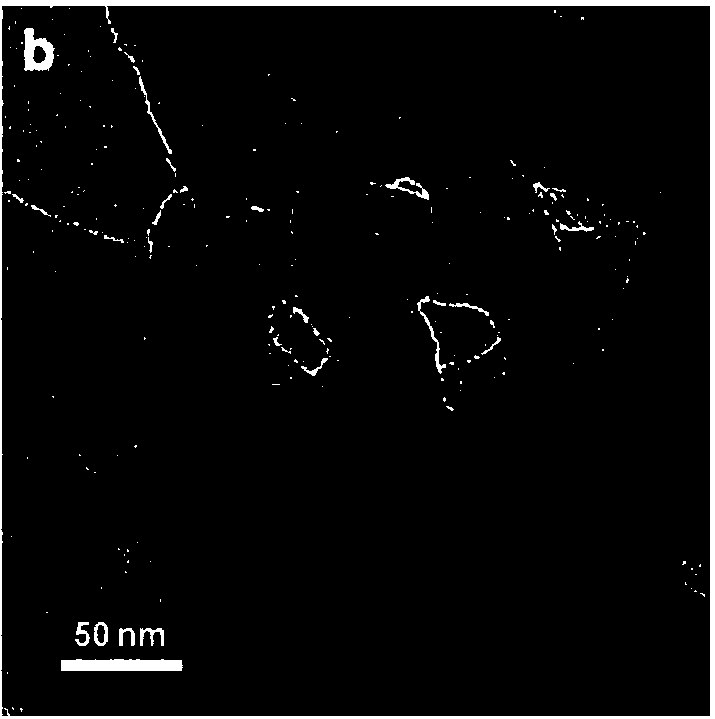

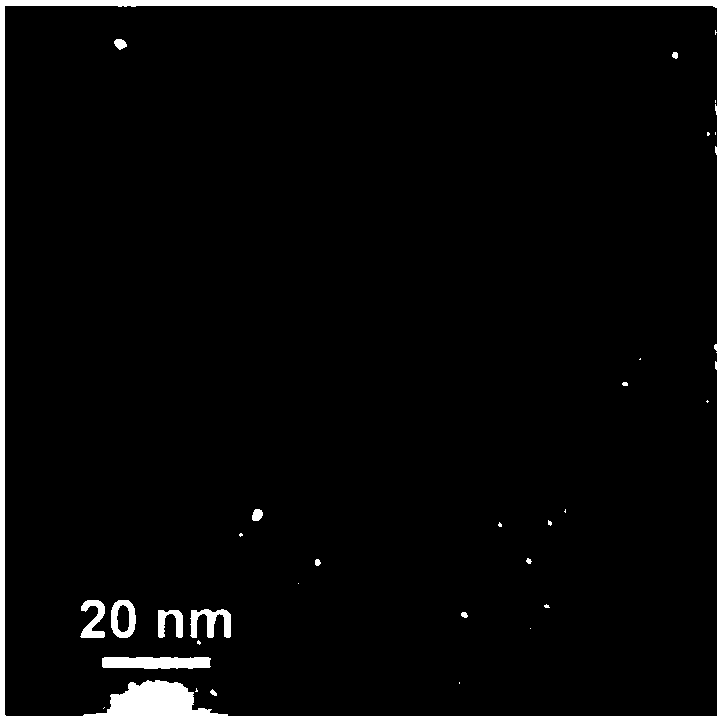

[0045] 0.658mL mass concentration is the phytic acid aqueous solution of 50%, the mixed solution of the deionized water of 3.5mL and 0.458mL aniline (analytical grade), and the 1mL aqueous solution containing 0.286g ammonium persulfate is cooled to 4 ℃ and then mixed rapidly, the The mixed solution was left to stand overnight and then soaked and washed with deionized water for two days; after freeze-drying, it was calcined at a high temperature, and the temperature was raised to 1000°C for 2 hours in a nitrogen atmosphere at a rate of 3°C / min. After cooling down to room temperature, it was taken out and ground to obtain Nitrogen and phosphorus co-doped carbon materials, the scanning electron micrograph and transmission electron micrograph are as follows Figure 1a-Figure 1b shown.

[0046] (2) Preparation of nitrogen-phosphorous co-doped carbon material hydrogen evolution catalyst loaded with platinu...

Embodiment 2

[0052] (1) Preparation of nitrogen and phosphorus co-doped carbon materials

[0053] Cool the mixed solution of 0.45mL 50% phytic acid aqueous solution, 3.5mL deionized water and 0.458mL aniline (analytical pure), and 1mL aqueous solution containing 0.286g ammonium persulfate to 4°C and mix quickly, and let the mixed solution stand After keeping overnight, soak and wash with deionized water for two days; after freeze-drying, perform high-temperature calcination, heat up to 600°C for 12 hours at a rate of 15°C / min in a nitrogen atmosphere, and wait until it cools down to room temperature, take it out and grind to obtain nitrogen and phosphorus co-doped complex carbon materials.

[0054] (2) Preparation of nitrogen-phosphorous co-doped carbon material hydrogen evolution catalyst loaded with platinum nanoparticles

[0055] Take 15mg of the above-prepared nitrogen-phosphorus co-doped carbon material and disperse it in 14mL aqueous solution and sonicate for 2h, then add 80μL of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com