Glufosinate ammonium water-soluble granule

A water-soluble granule, glufosinate-ammonium technology, applied in the field of pesticides, can solve problems such as flocculation, crystallization, and poor efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present application has no special limitation on the preparation method of the glufosinate-ammonium water-soluble granule, and it can be prepared in a manner well known to those skilled in the art. Exemplary, the preparation method of the glufosinate-ammonium water-soluble granule is specifically:

[0040] Mix glufosinate-ammonium, surfactant and filler to obtain the first product, or mix glufosinate-ammonium, surfactant, chelating agent, synergist and filler to obtain the first product;

[0041] The first product is mixed with water, then extruded, granulated and dried in sequence to obtain the glufosinate-ammonium water-soluble granule.

[0042] In the above process, the extrusion granulation and the drying are technical means well known to those skilled in the art, and there is no particular limitation in this application.

[0043] In the above process, the mass of the water is 3%-6% of the mass of the first product, and the drying temperature is preferably 40-9...

Embodiment 180

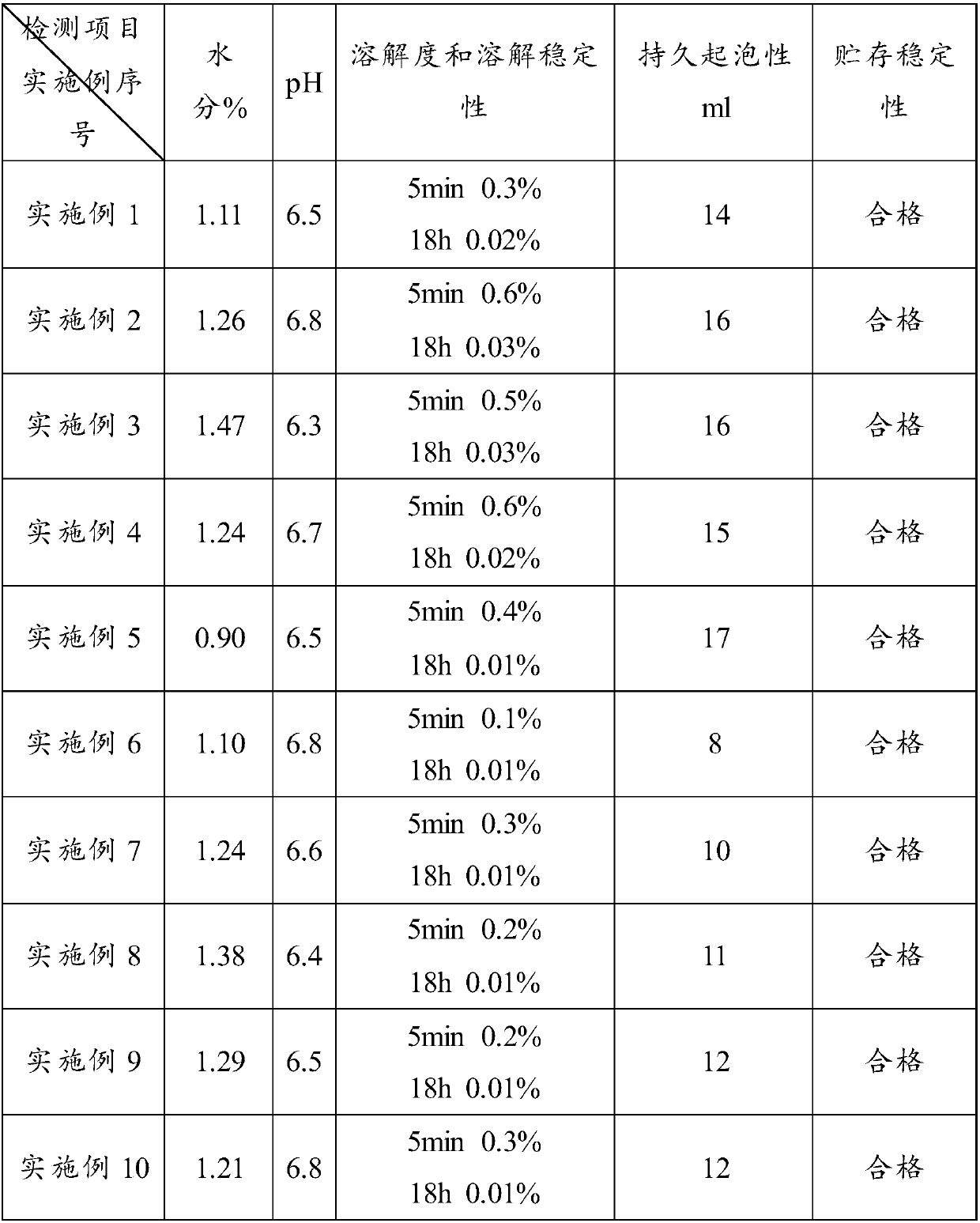

[0047] Embodiment 1 80% glufosinate-ammonium water-soluble granules

[0048] Glufosinate-ammonium technical 84.2g, (Hunstman, tallow amine polyoxyethylene ether) 5g, urea 5g and ammonium sulfate 5.8g are mixed, add the water of 3wt% of above-mentioned component total amount, throw in 1L kneader and fully knead, extrude granulation and dry, The mass fraction is 80% glufosinate-ammonium soluble granule finished product, and the yield is 99.5%; the former drug of glufosinate-ammonium in this implementation is the former drug of 95% glufosinate-ammonium.

Embodiment 297

[0049] Embodiment 2 97% glufosinate-ammonium water-soluble granules

[0050] Glufosinate-ammonium technical 97.4g, (Hunstman, tallow amine polyoxyethylene ether) 2g, urea 0.2g and ammonium sulfate 0.4g are mixed, add the water of 3.5wt% of above-mentioned component total amount, throw in 1L kneader and fully knead, extrude granulation and dry Dry to obtain a mass fraction of 97% glufosinate-ammonium soluble granule finished product, yield 99.2%; the former drug of glufosinate-ammonium is 99.6% former drug of glufosinate-ammonium in this implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com