Biomimetic cartilage material having biological activity and preparation method thereof

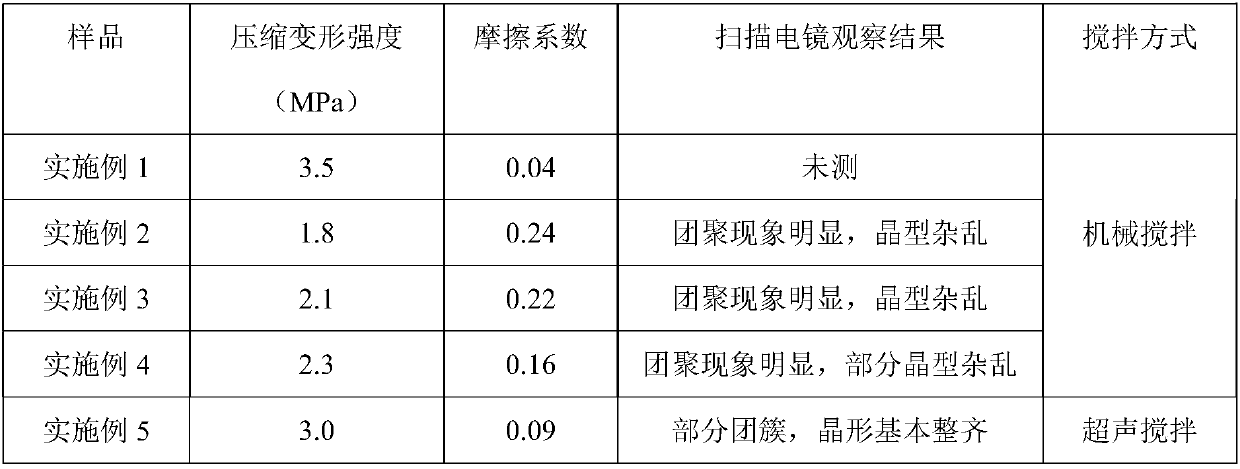

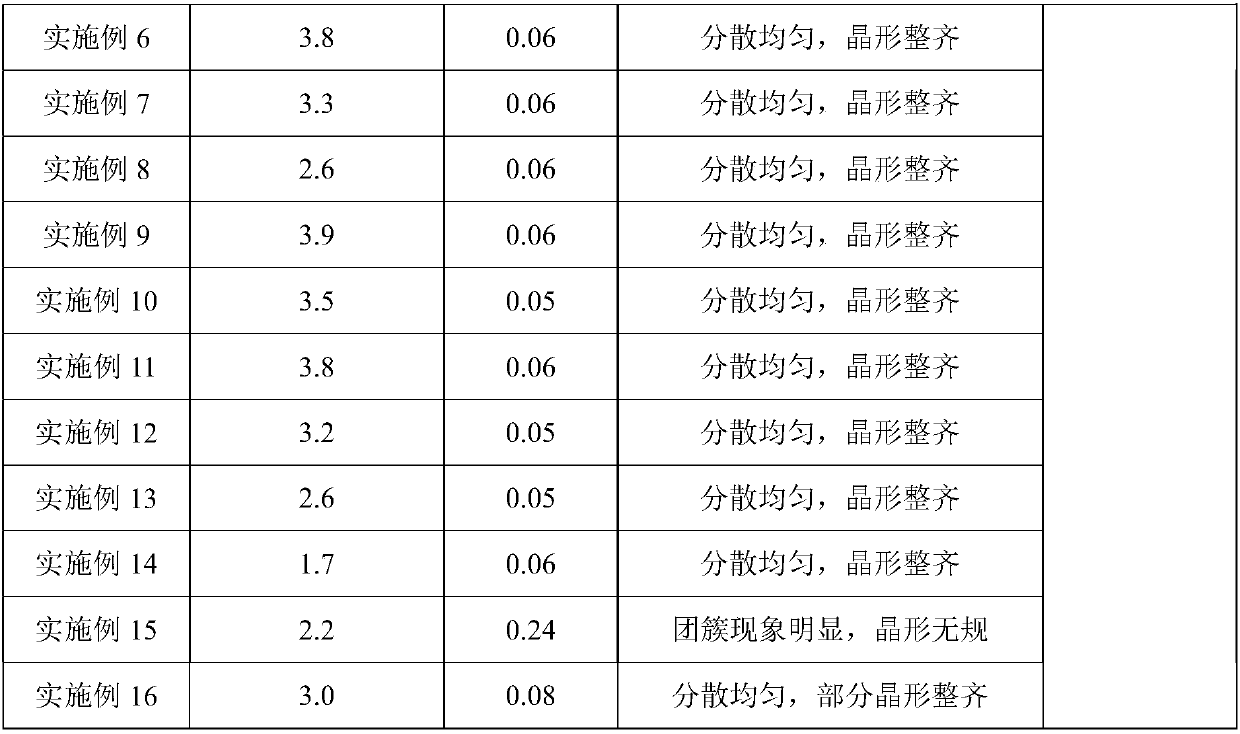

A technology of biological activity and biomaterials, applied in medical science, prostheses, etc., can solve problems such as insufficient mechanical strength, difficulty in control, cluster phenomenon, etc., achieve high tissue-inducing activity, good biological crystal form, and simple and efficient preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 20.0g of polyvinyl alcohol particles with a degree of polymerization n=1750±50 into 100mL of deionized water, stir and heat at 95°C for 6h to prepare a 20wt% polyvinyl alcohol aqueous solution, lower the temperature to 60°C, heat the solution to 98°C and let it stand After 2 hours of defoaming, pour the solution into a mold, put it into a refrigerator to freeze and shape it at -20°C for 16 hours, then take out the sample and place it at room temperature for 6 hours to thaw. Repeat the freezing and thawing process 5 times to obtain a physically cross-linked PVA hydrogel with 5 freezing and thawing times.

Embodiment 2

[0038] Add 20.0g of polyvinyl alcohol particles with a degree of polymerization n=1750±50 into 100mL of deionized water, stir and heat at 95°C for 6h to prepare a 20wt% polyvinyl alcohol aqueous solution, lower the temperature to 60°C, and add 2wt% of nano-hydroxyapatite Stone (purchased from Sigma-Aldrich Sigma-Aldrich (Shanghai) Trading Co., Ltd.), stirred overnight to make the reaction fully, and finally obtain the n-HA / PVA solution with a PVA matrix concentration of 20wt% and containing hydroxyapatite. After standing still for 2-8 hours for degassing, pour the solution into the mold, put it into the refrigerator to freeze and shape, the freezing temperature is -20°C, and the time is 16 hours, then take out the sample, and let it stand at room temperature for 6 hours to thaw. The above freezing and thawing process was repeated 5 times to prepare n-HA / PVA hydrogels with different concentrations of hydroxyapatite with 5 freezing and thawing times.

Embodiment 3

[0040] Add 20.0g of polyvinyl alcohol particles with polyvinyl alcohol n=1750±50 into 100mL of deionized water, stir and heat at 95°C for 6h to prepare a 20wt% polyvinyl alcohol aqueous solution, lower the temperature to 60°C, and add an appropriate amount of Ca (OH) 2 The powder was continuously stirred for 2 hours to prepare a uniform dispersion, and 2wt% of hydroxyapatite was added, and then the corresponding amount of H 3 PO 4 The ethanol solution (0.5mol / L) was stirred overnight to make the reaction fully, and finally the n-HA / PVA solution containing hydroxyapatite with a PVA matrix concentration of 20wt% was obtained. After the solution was left to stand for 2h to 8 hours to defoam, pour the solution into a mold, put it into the refrigerator to freeze and shape, the freezing temperature was -20°C, and the time was 16h. Then the sample was taken out and left at room temperature for 6h to thaw. The above freeze-thaw process was repeated 5 times to obtain a physically cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com