A kind of preparation method of polyaluminum chloride

A technology of polyaluminum chloride and mixed solution, which is applied in the fields of aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of high production cost, high impurity content, and low active ingredient, and achieve product quality High, high product purity, the effect of improving the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

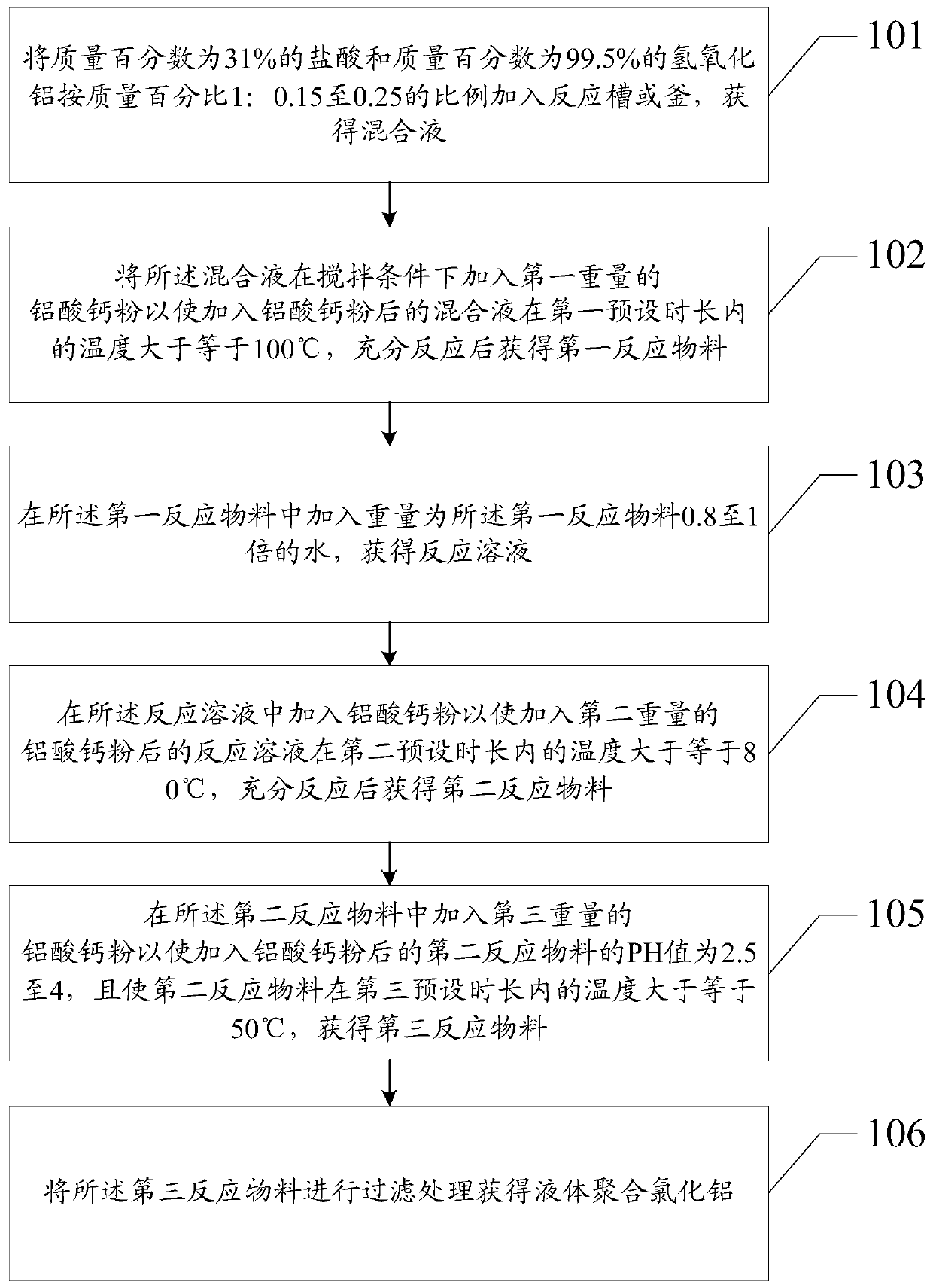

[0036] Embodiment 1 of the present application provides a method for preparing polyaluminum chloride, the method comprising:

[0037] Step 101: adding 31% by weight hydrochloric acid and 99.5% by weight aluminum hydroxide to a reaction tank or kettle at a ratio of 1:0.15 to 0.25 by weight to obtain a mixed solution;

[0038] Step 102: Add the first weight of calcium aluminate powder to the mixed solution under stirring conditions, so that the temperature of the mixed solution after adding the calcium aluminate powder is greater than or equal to 100°C within the first preset time period, and after fully reacting obtaining a first reaction material;

[0039] Step 103: adding 0.8 to 1 times the weight of water to the first reaction material to obtain a reaction solution;

[0040] Step 104: Adding a second weight of calcium aluminate powder to the reaction solution so that the temperature of the reaction solution after adding the calcium aluminate powder is greater than or equal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com