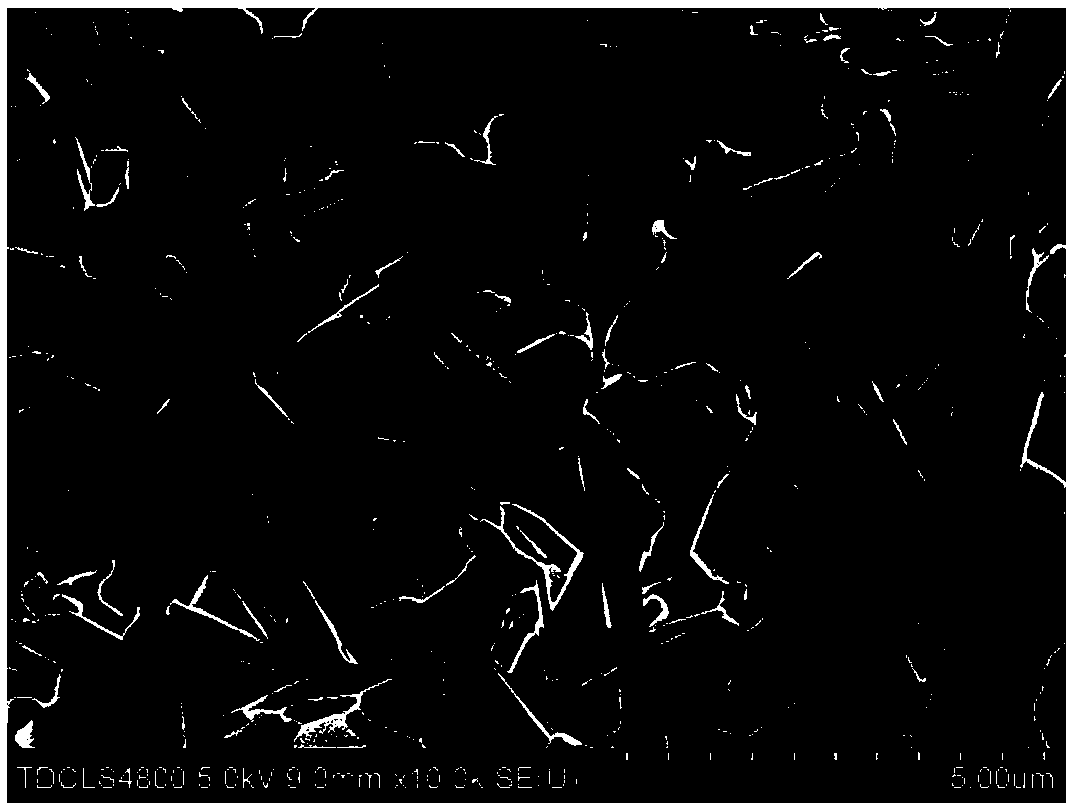

Microscopic layered interlocked nanocrystalline ceramic corundum abrasive and preparation method thereof

A technology of ceramic corundum and nanocrystals, applied in chemical instruments and methods, and other chemical processes, can solve problems such as low toughness and single microscopic morphology, and achieve the effects of improving abrasive performance, reducing firing temperature, and reducing production temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 90.00gAl(NO 3 ) 3 9H 2 O, 6.45g PEG1000 dissolved in water, dubbed Al 3+ A solution with a concentration of 0.35mol / L;

[0026] Slowly add diluted ammonia water dropwise to the above solution, keep stirring, control the pH to 9.2, make it continue to react until it is completely gelled, and then undergo suction filtration and repeated washing to obtain Al(OH) 3 Gel precursor.

[0027] Add 0.15wt% (0.135g) additive to Al(OH) 3 Into the gel precursor, 0.40wt% (0.360g) alumina seeds were added. Using corundum balls, wet ball milling to make it fully mixed; the composition and mass percentage content of the additives are: 55.5% C 16 h 36 o 4 Ti, 22.3% CaF 2 , 11.1% Y (NO 3 ) 3 ·6H 2 O, 11.1% Ce(NO 3 ) 3 ·6H 2 O.

[0028] The ball-milled wet gel was dried at 50°C to obtain a dry gel, and then crushed, granulated, and sieved to obtain sintered precursor particles.

[0029] The precursor particles are calcined at 1400°C, and then sieved to obtain ceramic ...

Embodiment 2

[0032] Take 90.00gAl(NO 3 ) 3 9H 2O, 6.45g PEG1000 dissolved in water, dissolved in water, dubbed Al 3+ A solution with a concentration of 0.40mol / L.

[0033] Slowly add diluted ammonia water dropwise to the above solution, keep stirring, control the pH to 9.4, make it continue to react until it is completely gelled, and then undergo suction filtration and repeated washing to obtain Al(OH) 3 Gel precursor.

[0034] Add 0.30wt% (0.270g) additive to Al(OH) 3 Into the gel precursor, 0.50wt% (0.450g) alumina seeds were added. Using corundum balls, wet ball milling to make it fully mixed; the composition and mass percentage content of the additives are: 45.4% C 16 h 36 o 4 Ti, 27.3% CaF 2 , 7.3% Y (NO 3 ) 3 ·6H 2 O,20%Ce(NO 3 ) 3 ·6H 2 O.

[0035] The wet gel after ball milling was dried at 70° C. to obtain a dry gel, and then crushed, granulated, and sieved to obtain sintered precursor particles.

[0036] The precursor particles are calcined at 1350°C, and then si...

Embodiment 3

[0039] Take 90.00gAl(NO 3 ) 3 9H 2 O, 6.45g PEG1000 dissolved in water, dubbed Al 3+ A solution with a concentration of 0.50mol / L;

[0040] Slowly add diluted ammonia water dropwise to the above solution, keep stirring, control the pH to 9.6, make it continue to react until it is completely gelled, and then undergo suction filtration and repeated washing to obtain Al(OH) 3 Gel precursor.

[0041] Add 0.50wt% (0.450g) additive to Al(OH) 3 Into the gel precursor, 0.40wt% (0.360g) alumina seeds were added. Using corundum balls, wet ball milling to make it fully mixed; the composition and mass percentage content of the additives are: 38.5%C 16 h 36 o 4 Ti, 23.0% CaF 2 , 30%Y (NO 3 ) 3 ·6H 2 O, 8.5% Y (NO 3 ) 3 ·6H 2 O.

[0042] The ball-milled wet gel was dried at 90°C to obtain a dry gel, and then crushed, granulated, and sieved to obtain sintered precursor particles.

[0043] The precursor particles are calcined at 1300°C, and then sieved to obtain ceramic corun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com