A kind of preparation method of cationic water-soluble polymer

A water-soluble polymer and cationic technology, applied in chemical instruments and methods, natural water treatment, textile industry wastewater treatment, etc., can solve the problems of low cost, high bridging ability, high flocculation, etc., and achieve good flocculation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

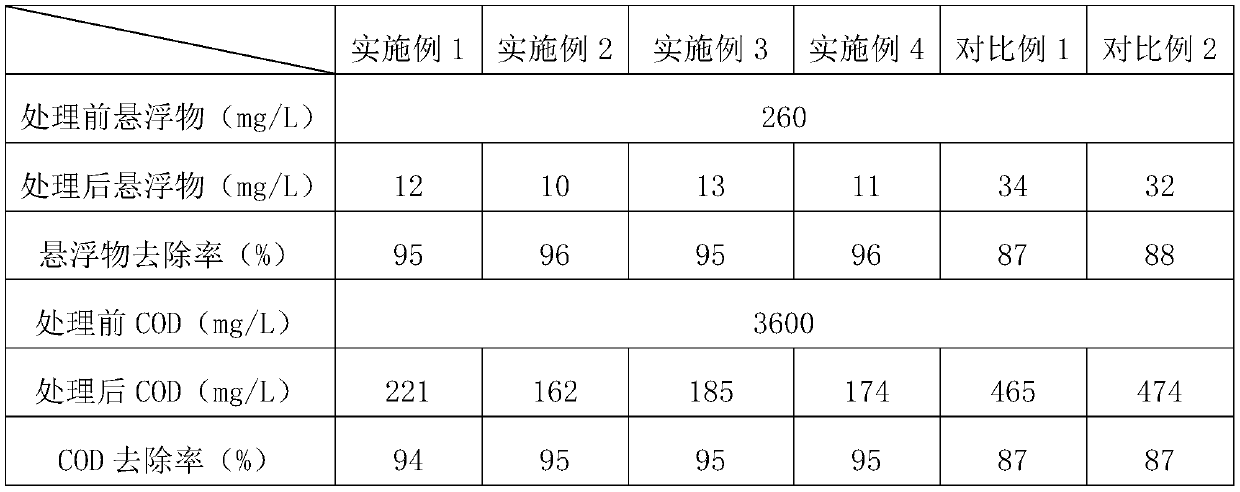

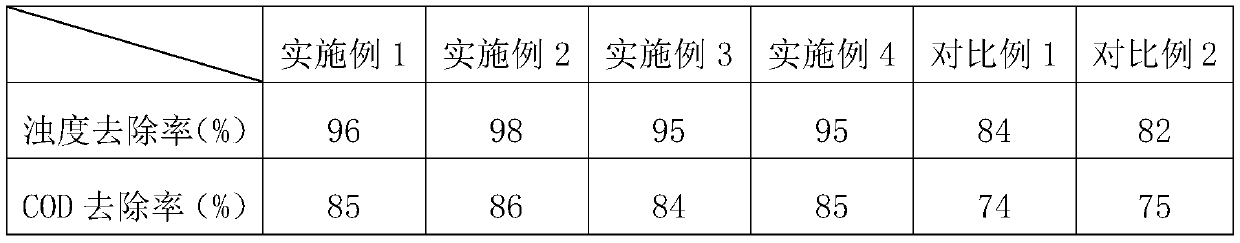

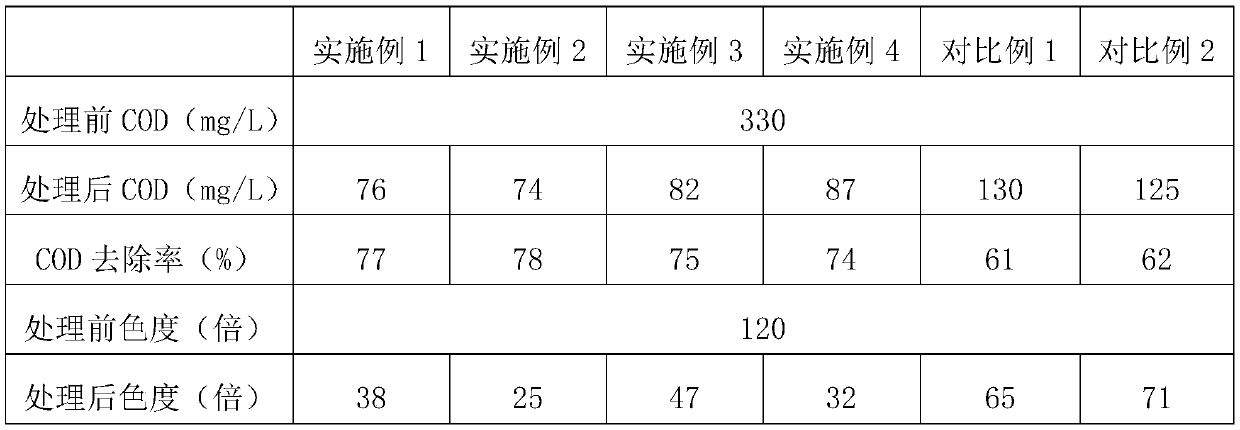

Examples

preparation example Construction

[0020] The present embodiment provides a kind of preparation method of cationic water-soluble polymer, comprising the following steps:

[0021] (1) Synthesis of cationic water-soluble acrylic resin: prepare a mixed solution including acrylic acid, butyl acrylate, β-hydroxyethyl methacrylate, methyl methacrylate and initiator for subsequent use, and put the solvent into a four-neck bottle , heat up to 80-100°C, then add 10-30% mixed solution to the solvent, keep warm for 10-50min, then add the remaining mixed solution dropwise, keep warm for 1-3 hours, then add initiator and solvent, then Insulate and react for 1-3 hours, and finally add methacryloyloxyethyltrimethylammonium chloride dropwise, and insulate for 1-3 hours to prepare a cationic water-soluble acrylic resin;

[0022] (2) Synthesis of cationic water-soluble polymer: mix cationic water-soluble acrylic resin and hexamethoxymethylmelamine in volume ratio of 80-100:10-30 to prepare cationic water-soluble polymer.

[002...

Embodiment 1

[0035]Synthesis of cationic water-soluble acrylic resin: 5.5 mL of methyl methacrylate, 3.5 mL of β-hydroxyethyl methacrylate, 2 mL of acrylic acid, 16 mL of butyl acrylate, and the initiator benzoyl peroxide (BPO) were mixed to obtain mixture. In a four-neck flask equipped with a stirrer, a thermometer, a constant pressure low liquid funnel and a condenser, add 20ml of n-butanol solution, start stirring, heat up the constant temperature water bath to 90°C, first add 20% of the mixed solution dropwise, and keep warm for 30min Finally, add the remaining 80% of the mixed solution dropwise at a constant speed, and the dropwise addition is completed in 2.5-4 hours. After 2 hours of heat preservation, add a certain amount of benzoyl peroxide (BPO) and 5ml n-butanol. 1.25% of the total mass of the body. Finally, keep warm for 2 hours, and then dropwise add methacryloyloxyethyltrimethylammonium chloride, the amount of which accounts for 18% of the total mass of the monomers, keep wa...

Embodiment 2

[0039] Synthesis of cationic water-soluble acrylic resin: 5.5 mL of methyl methacrylate, 4.5 mL of β-hydroxyethyl methacrylate, 5 mL of acrylic acid, 12 mL of butyl acrylate, and the initiator benzoyl peroxide (BPO) were mixed to obtain mixture. Add 45ml of n-butanol solution to a four-necked flask equipped with a stirrer, a thermometer, a constant-pressure low-liquid funnel, and a condenser tube, start stirring, raise the temperature to 90°C in a constant-temperature water bath, first add 10% of the mixed solution dropwise, and keep warm for 30 minutes Finally, add the remaining 90% mixed solution dropwise at a constant speed, and the dropwise addition is completed in 3 hours. After 2 hours of insulation, add a certain amount of benzoyl peroxide (BPO) and 14ml n-butanol. 1.25% of mass. Finally, keep warm for 2 hours, and then dropwise add methacryloyloxyethyltrimethylammonium chloride, the amount of which accounts for 15% of the total mass of the monomers, keep warm for 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com