Preparation method and application of low formaldehyde-emission soft melamine formaldehyde foam

A melamine formaldehyde, low formaldehyde release technology, applied in mechanical equipment, internal combustion piston engines, combustion engines, etc., can solve the problems of foam mechanical properties, low formaldehyde release, poor mechanical properties and other problems, achieve excellent mechanical properties, reduce free Formaldehyde content, the effect of increasing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

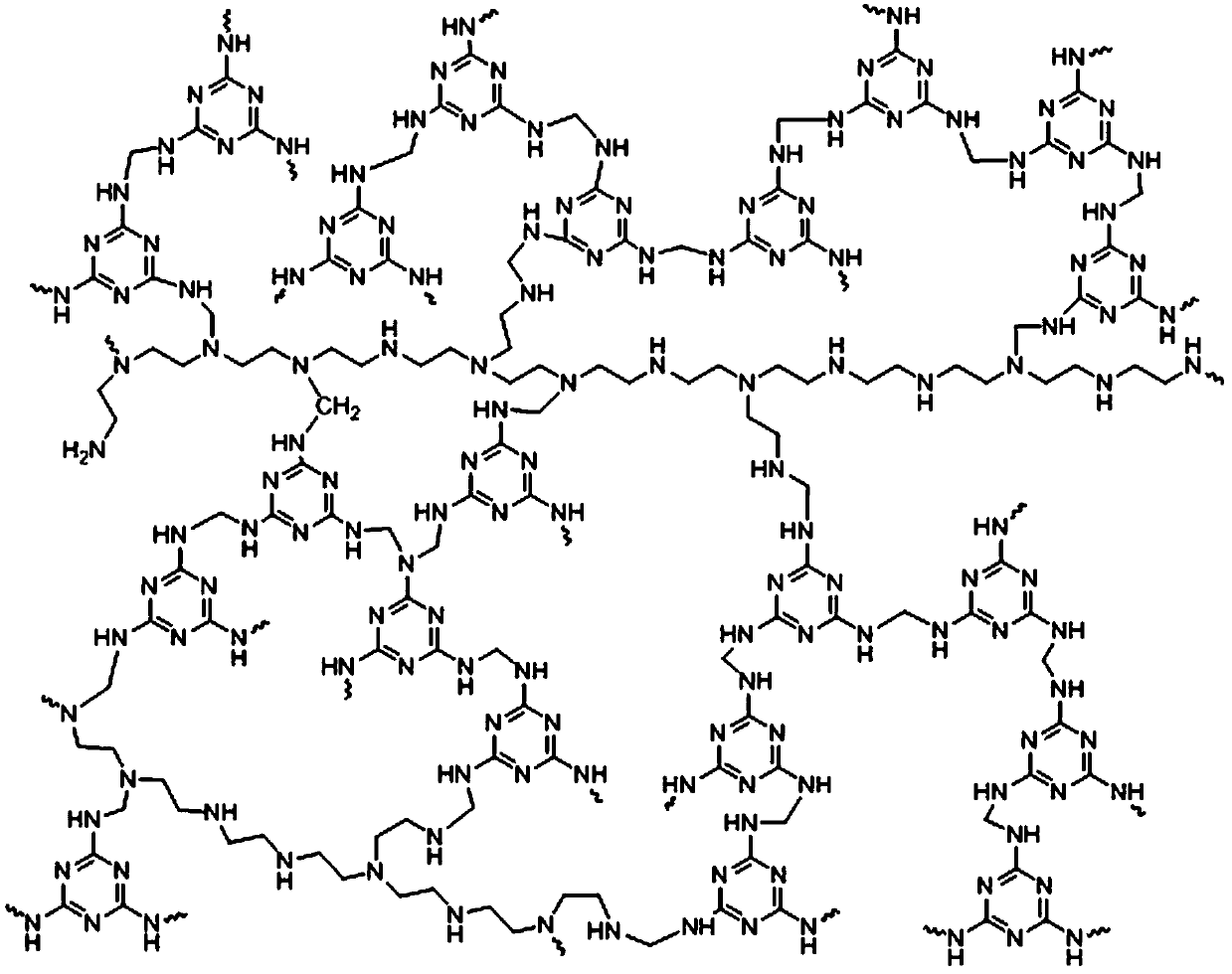

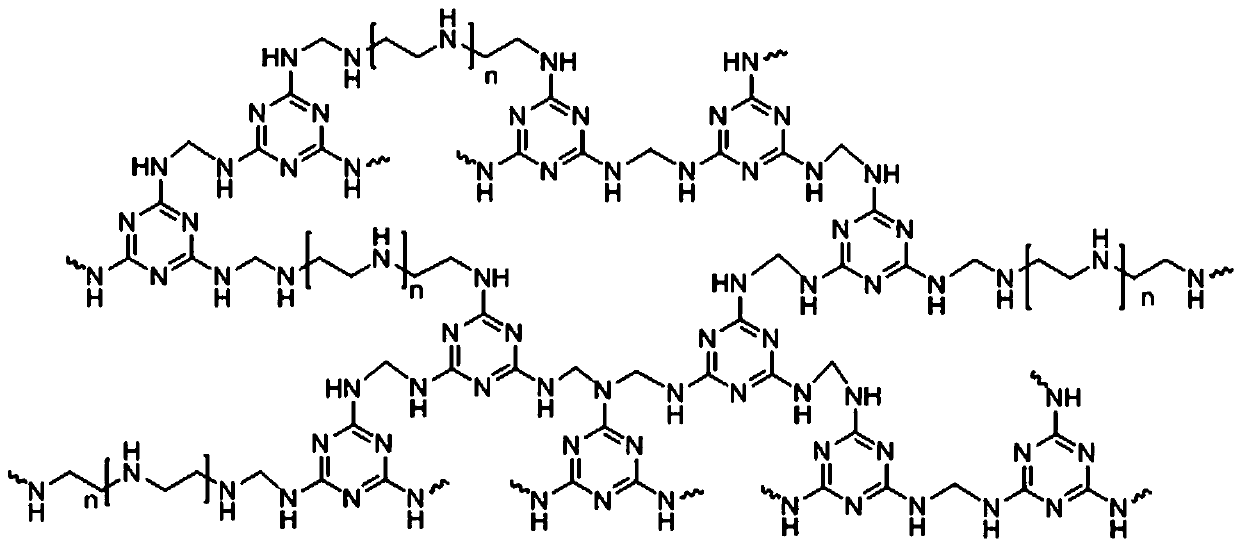

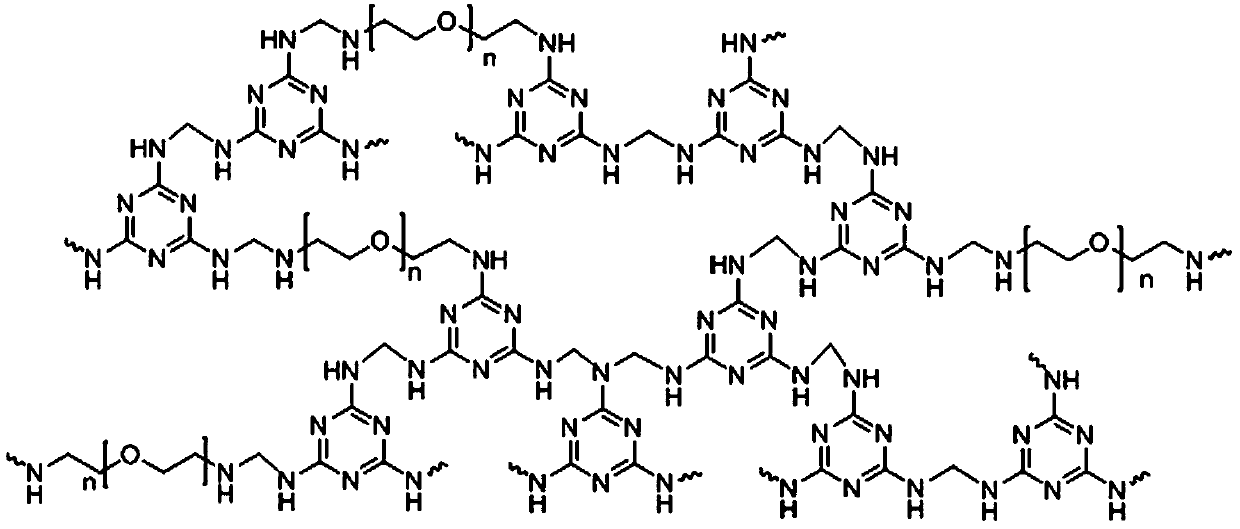

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add melamine and solid paraformaldehyde into the reaction kettle at a molar ratio of 1:2, raise the temperature to 60°C, add catalyst sodium hydroxide aqueous solution to adjust the pH of the system to 8.5 after the solid paraformaldehyde is dissolved, and then raise the temperature to 85 ℃, add 4 parts of polyethylenimine after reacting for 35min, and discharge after the cloud point occurs in the reaction to obtain the modified melamine formaldehyde resin prepolymerization solution; then the modified resin solution obtained (modified melamine formaldehyde resin prepolymerization solution ) into a water bath at 25°C for cooling.

[0039] Add 6 parts of TW-20, 22 parts of n-pentane, and 8 parts of ammonium chloride to 100 parts of the modified melamine formaldehyde resin prepolymerization solution obtained by the above method, and then emulsify for 2 minutes under a high-speed emulsifier, and then pour the emulsion Put it into a mold, place it in a microwave device to fo...

Embodiment 2

[0042] Add melamine and solid paraformaldehyde into the reaction kettle at a molar ratio of 1:2.5, raise the temperature to 60°C, add catalyst sodium hydroxide aqueous solution to adjust the pH of the system to 8.5 after the solid paraformaldehyde is dissolved, then raise the temperature to 85°C , add 10 parts of polyethylenimine after reacting for 40min, when the cloud point occurs in the reaction, the material is discharged to obtain the modified melamine formaldehyde resin prepolymerization liquid; then the modified resin liquid (modified melamine formaldehyde resin prepolymerization liquid) obtained Cool in a water bath at 25°C.

[0043] Add 6 parts of TW-80, 22 parts of isopentane, and 10 parts of hydrochloric acid to 100 parts of the modified melamine-formaldehyde resin prepolymerization solution obtained by the above method, and then emulsify for 2 minutes under the high-speed emulsifier, and then pour the emulsion into the mold placed in a microwave device for foaming ...

Embodiment 3

[0046] Add melamine and solid paraformaldehyde into the reaction kettle at a molar ratio of 1:3, raise the temperature to 60°C, add catalyst sodium hydroxide aqueous solution to adjust the pH of the system to 8.5 after the solid paraformaldehyde is dissolved, then raise the temperature to 85°C , add 15 parts of polyethylenimine after reacting for 40min, when the cloud point occurs in the reaction, the material is discharged to obtain the modified melamine formaldehyde resin prepolymerization liquid; then the modified resin liquid (modified melamine formaldehyde resin prepolymerization liquid) obtained Cool in a water bath at 25°C.

[0047] Add 8 parts of TW-40, 23 parts of petroleum ether, and 12 parts of sulfuric acid to 100 parts of the modified melamine-formaldehyde resin prepolymerization solution obtained by the above method, and then emulsify for 2 minutes under the high-speed emulsifier, and then pour the emulsion into the mold , placed in a microwave device for foaming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com