Micro-fluidic chip having three-dimensional graphene interface, and production method thereof

A microfluidic chip, graphene technology, applied in biochemical equipment and methods, enzymology/microbiology devices, tissue cell/virus culture devices, etc. Small contact area, unfavorable cell biological characteristics, etc., to achieve good application prospects, good biocompatibility, and controllable process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

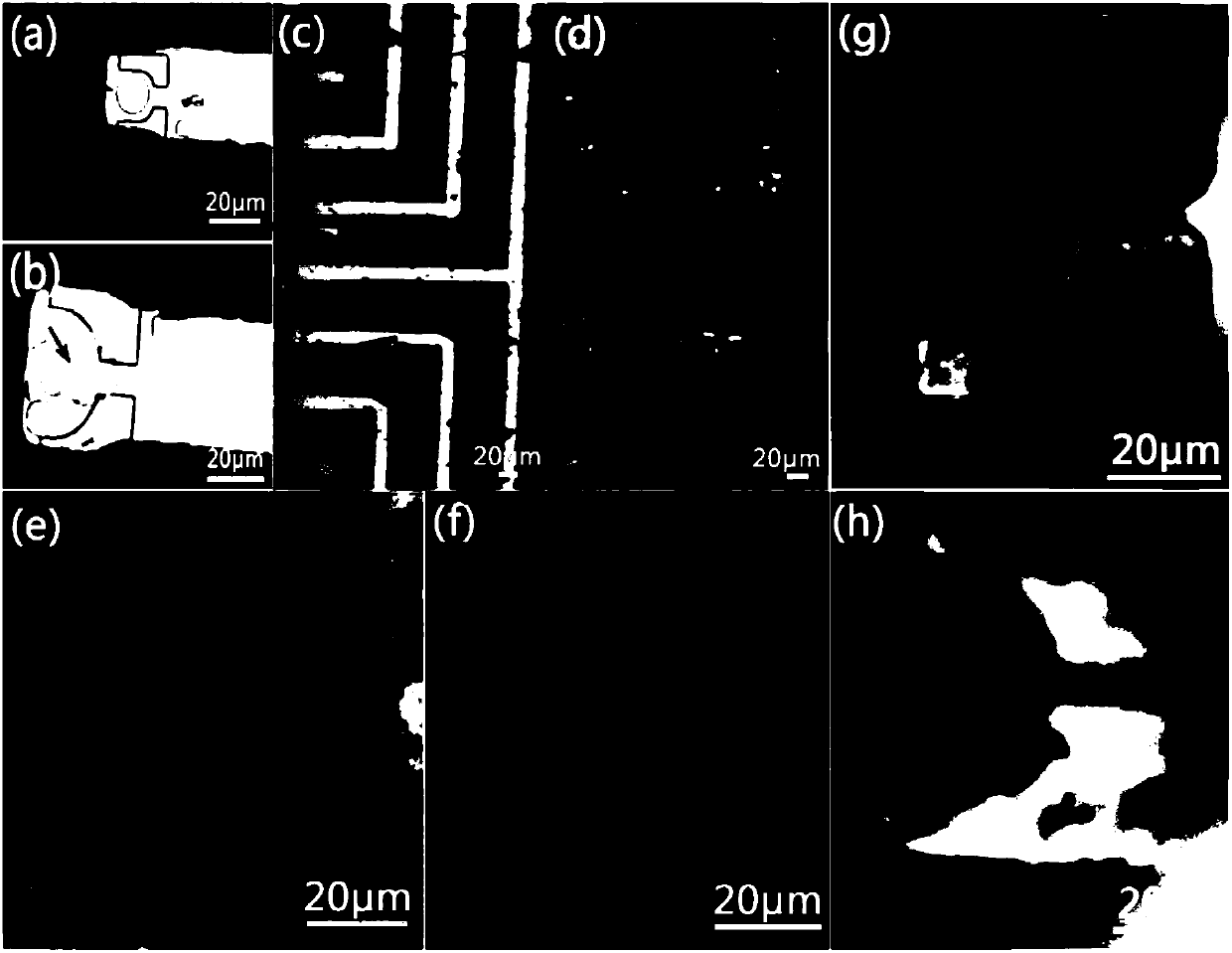

[0041] The object of the present invention is to prepare a microfluidic chip with a three-dimensional graphene interface, the microfluidic chip includes two liquid storage tanks and a test flow channel between the two liquid storage tanks to form an H-shaped PDMS flow channel, And the daughter chip arranged in the test channel 21, such as figure 1 As shown, can also include openable PDMS cover ( figure 1 shaded part); planar structure parts such as figure 2 and 3 As shown, the H-shaped PDMS flow channel can prevent the clogging of the microfluidic chip when the cells are injected. The chiplet includes a central reference electrode 20 and one or more mutually independent cell electrodes symmetrically arranged on both sides of the central reference electrode 20 .

[0042] The chiplet adopts as Figure 4 The cell electrode 10 shown includes an electrode base 11 and a capture groove 12 located on the electrode base 11. The capture groove 12 is composed of a plurality of micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com