A cross-shaped permanent cool feeling antibacterial regenerated cellulose fiber and its preparation method

A regenerated cellulose, cross-shaped technology, applied in the field of viscose fiber, can solve the problems of poor wearing comfort of the fiber, non-degradable product waste, unsustainable petrochemical raw materials, etc. The effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

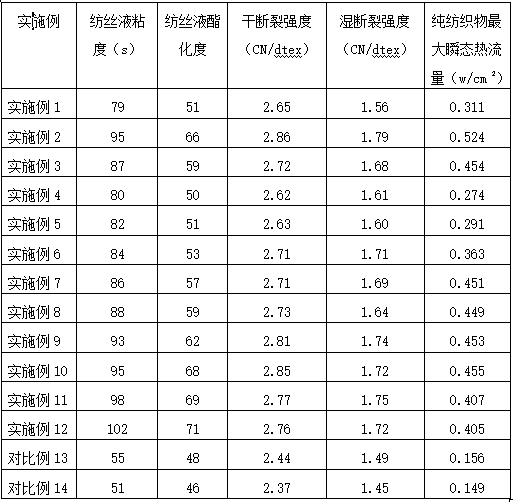

Examples

Embodiment 1

[0033] Example 1 Preparation of a cross-shaped permanent cool feeling antibacterial regenerated cellulose fiber

[0034] 1. Preparation of spinning dope

[0035] After mixing five batches of cotton pulp and bamboo pulp with a degree of polymerization of about 900 and a cellulose content of 95%, they are fully mixed with the impregnating lye, and soaked in a 238±1g / L, 50°C sodium hydroxide alkali solution for 60 minutes. Alkali cellulose is made by pressing; the alkali cellulose is crushed and aged, the aging temperature is 22°C, and the aging time is 1h; then it is mixed with CS 2 Mix for yellowing reaction, yellowing temperature is 18°C, yellowing time is 60 minutes, and the amount of carbon disulfide added to methyl cellulose is 36% during yellowing to generate cellulose xanthate; after initial dissolution of cellulose xanthate in dilute alkali solution Obtain the spinning stock solution, add 4.5% denaturing agent to methyl fiber in the later stage of dissolving, and it is ...

Embodiment 2

[0050] Example 2 Preparation of a cross-shaped permanent cool feeling antibacterial regenerated cellulose fiber

[0051] 1. Preparation of spinning dope

[0052] Five batches of wood pulp and bamboo pulp with a degree of polymerization of 1300 and a cellulose content of 98% are mixed and put into alkaline solution to make alkali cellulose, which is then crushed and aged to yellowing treatment; the yellowing temperature is 18°C , time 60min, carbon disulfide added 44% to methyl cellulose during yellowing to generate cellulose xanthate; cellulose xanthate added 4.5% denaturant to methyl cellulose in the later stage of dissolution, and its composition was 2.5% polyethylene glycol Alcohol and 2% diethylamine; the fully dissolved cellulose sulfonate is filtered through three times, defoamed and matured to obtain the spinning dope. Spinning dope index: methyl fiber: 9.89wt%, alkali content 8.53%, maturity 26ml, esterification degree 66, viscosity 95S.

[0053] 2. Preparation of pe...

Embodiment 3

[0064] Example 3 Preparation of a cross-shaped permanent cooling antibacterial regenerated cellulose fiber

[0065] 1. Preparation of spinning dope

[0066] Five batches of wood pulp and bamboo pulp with a polymerization degree of about 1000 and a cellulose content of 96% are mixed and soaked to make alkali cellulose; the alkali cellulose is then pulverized, aged, yellowed, and yellowed When adding 40% of carbon disulfide to methyl fiber, cellulose xanthate is generated; cellulose xanthate is initially dissolved in dilute alkali solution to obtain spinning stock solution, and 4.5% denaturant of methyl fiber is added in the later stage of dissolution, and its The composition is 1.5% of alkylamine polyethylene glycol and 3% of polyoxyethylene; the spinning stock solution is sequentially subjected to post-dissolution, three filtrations, defoaming, and aging to obtain the spinning stock solution. Spinning dope index: methyl fiber: 9.01wt%, alkali content 7.48%, esterification deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com