Composite fluorescent biosensor, and preparation method and application thereof

A biosensor and composite fluorescence technology, applied in fluorescence/phosphorescence, material excitation analysis, etc., to achieve good selectivity and stability, good market application prospects, industrial production value, and accurate detection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

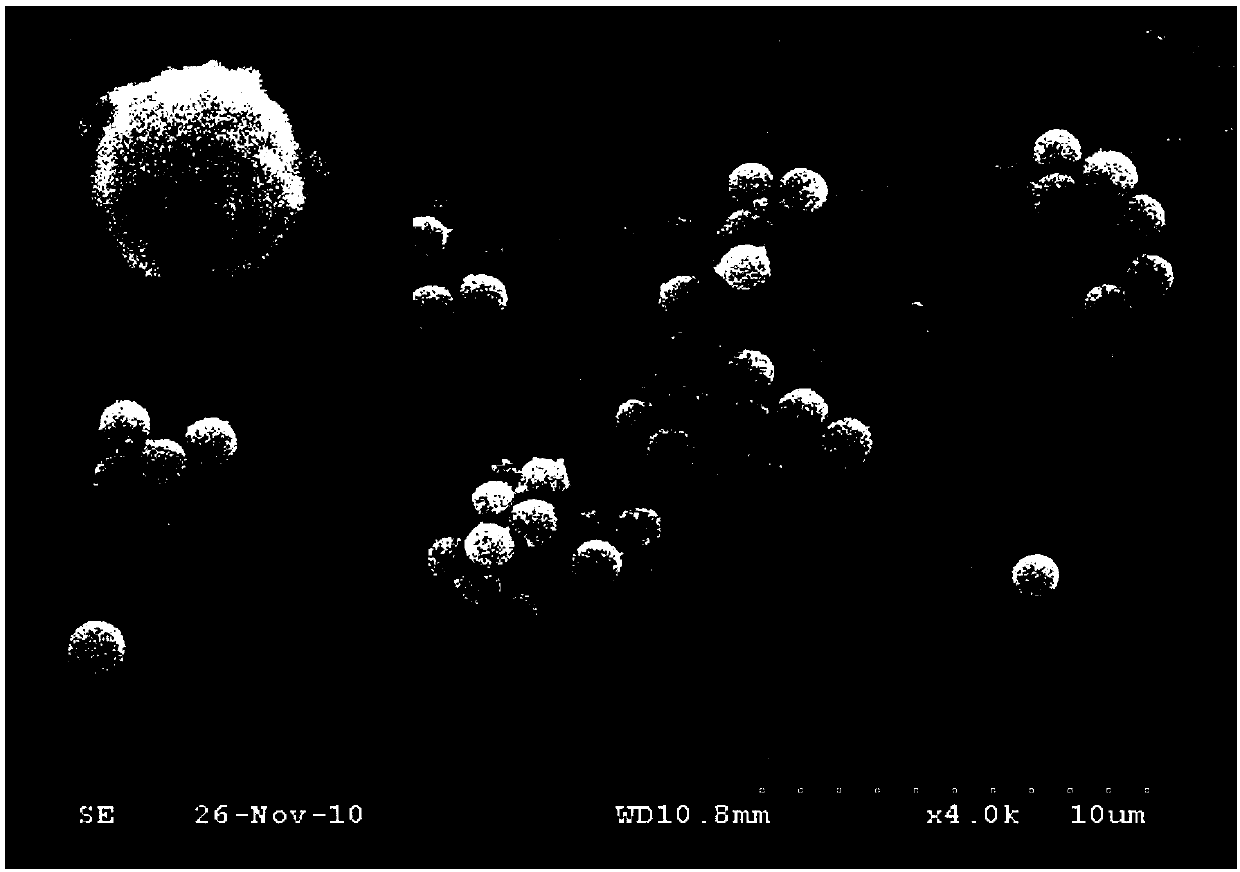

[0046] In a 50mL three-necked flask, mix melamine and formaldehyde solution (concentration: 37%) according to the molar ratio of 1: (3-5), stir mechanically, heat to 60°C in a water bath and react for 20min to obtain prepolymer methylol melamine. Add polyvinyl alcohol as a dispersant in a 250mL three-necked bottle, and dissolve it in 90g of deionized water with mechanical stirring in a water bath. After it is completely dissolved, use acetic acid to adjust the pH value of the system to weak acidity and adjust to the predetermined temperature. Add the prepolymer into the polyvinyl alcohol solution, and stir at the same time, start timing when the system appears white turbidity, stop heating after about 30 minutes of reaction, cool with ice water, and terminate the reaction. The obtained product dispersion system is centrifuged at high speed by a centrifuge to separate the precipitate, remove the supernatant, add deionized water to redisperse, wash and centrifuge three times, and...

Embodiment 2

[0050] In a 50mL three-neck flask, mix melamine and formaldehyde solution (concentration: 37%) according to the molar ratio of 1: (3-5), stir mechanically, heat to 60°C in a water bath and react for 20min to obtain a prepolymer methylolmelamine. Add polyvinyl alcohol as a dispersant in a 250mL three-necked bottle, and dissolve it in 90g of deionized water with mechanical stirring in a water bath. After it is completely dissolved, use acetic acid to adjust the pH value of the system to weak acidity and adjust to the predetermined temperature. Add the prepolymer into the polyvinyl alcohol solution, and stir at the same time, start timing when the system appears white turbidity, stop heating after about 30 minutes of reaction, cool with ice water, and terminate the reaction. The obtained product dispersion system is centrifuged at high speed by a centrifuge to separate the precipitate, remove the supernatant, add deionized water to redisperse, wash and centrifuge three times. The...

Embodiment 3

[0056] In a 50mL three-necked flask, mix melamine and formaldehyde solution (concentration: 37%) according to the molar ratio of 1: (3-5), stir mechanically, heat to 60°C in a water bath and react for 20min to obtain prepolymer methylol melamine. Add polyvinyl alcohol as a dispersant in a 250mL three-necked bottle, and dissolve it in 90g of deionized water with mechanical stirring in a water bath. After it is completely dissolved, use acetic acid to adjust the pH value of the system to weak acidity and adjust to the predetermined temperature. Add the prepolymer into the polyvinyl alcohol solution, and stir at the same time, start timing when the system appears white turbidity, stop heating after about 30 minutes of reaction, cool with ice water, and terminate the reaction. The obtained product dispersion system is centrifuged at high speed by a centrifuge to separate the precipitate, remove the supernatant, add deionized water to redisperse, wash and centrifuge three times. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com