Composite photocatalyst and its preparation method and application

A technology of catalyst and compound light, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc., which can solve the problems of biodegradation, fetal teratogenicity, and human health etc. to achieve the effects of increasing the specific surface area and surface active sites, reducing reaction costs, and excellent photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

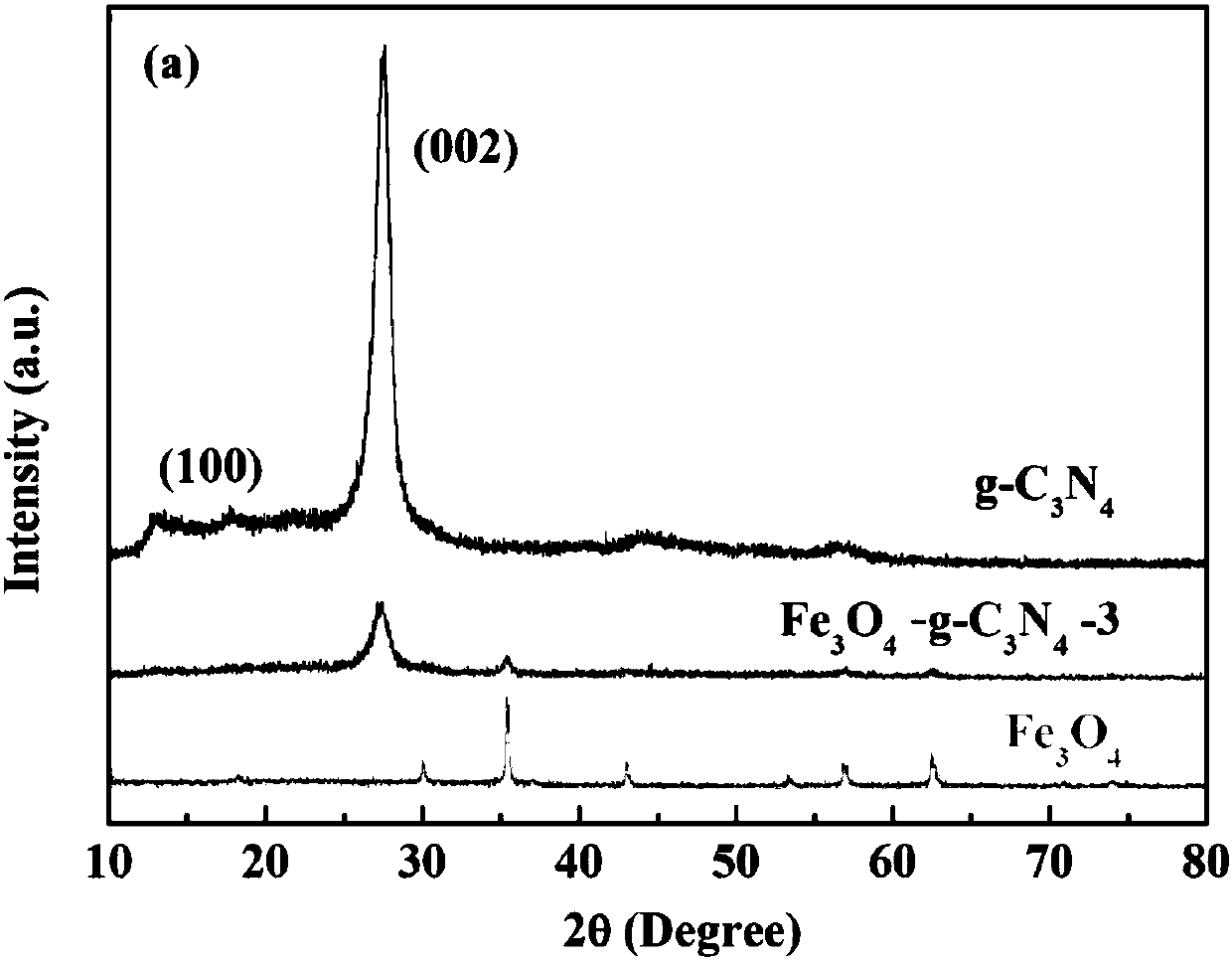

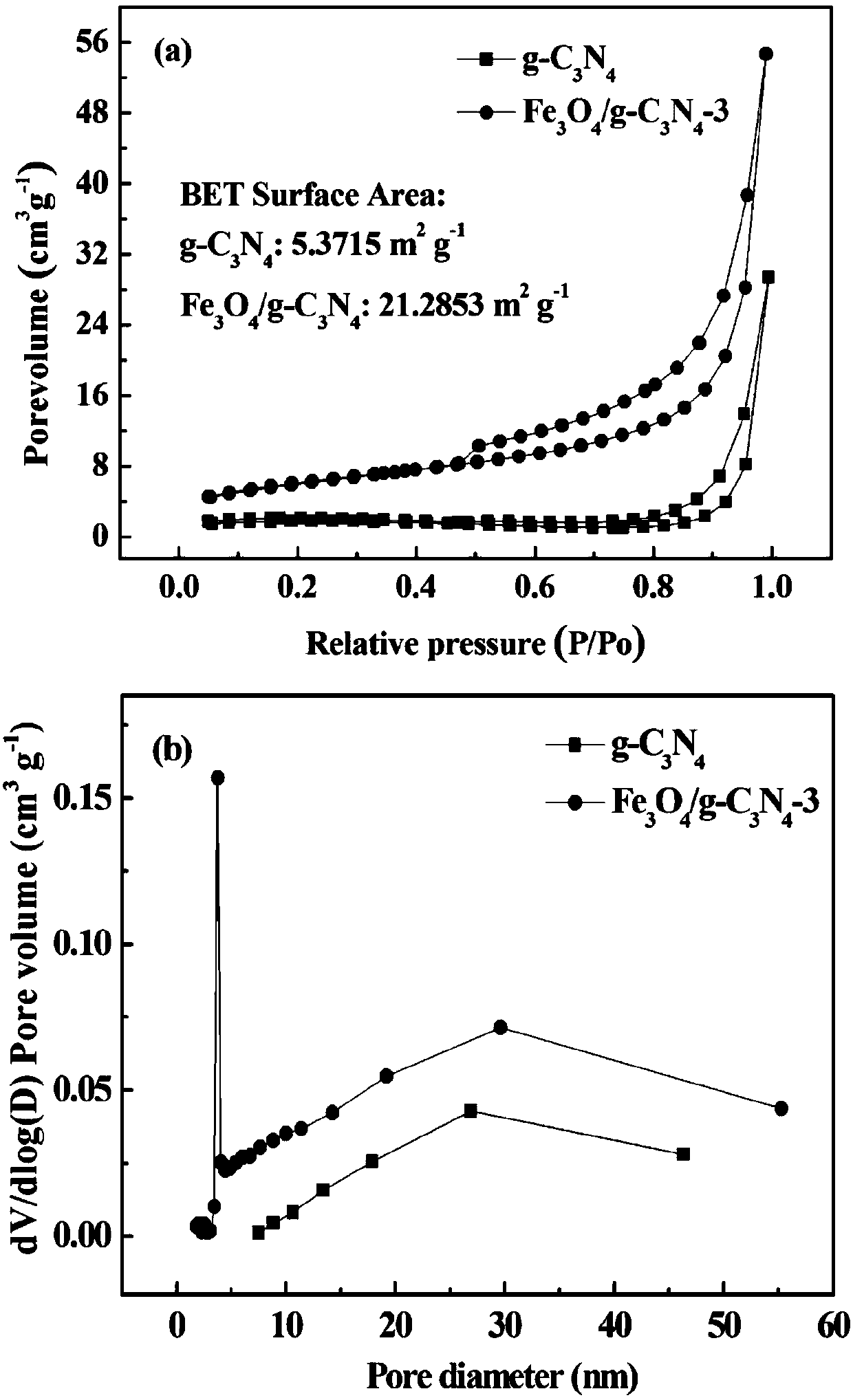

[0031] Example 1: 10wt% Fe 3 o 4 / g -C 3 N 4 Preparation of Mesoporous Composite Photocatalyst

[0032] 1. Preparation of g-C 3 N 4 catalyst of light

[0033] 1. Put melamine into an open crucible and heat at 2°C min -1 The heating rate is from room temperature to 550°C and kept for 4h.

[0034] 2. After cooling to room temperature, take out the yellow solid and grind it to powder with an agate mortar to obtain mesoporous g-C 3 N 4 catalyst of light.

[0035] 2. Preparation of 10wt% Fe 3 o 4 / g -C 3 N 4 Mesoporous Composite Photocatalyst

[0036] 1. Weigh 0.1750g of ferric chloride hexahydrate and dissolve it in 35mL of ethylene glycol and stir to obtain solution A.

[0037] 2. Add 3.6 g of sodium acetate to solution A to form solution B.

[0038] 3. Add 0.5g of g-C to solution B 3 N 4 , magnetically stirred for 12 h to form solution C.

[0039] 4. Transfer the solution C to a reaction kettle, and react in an oven at 200° C. for 6 hours.

[0040] 5. After n...

Embodiment 2

[0041] Example 2: 15wt% Fe 3 o 4 / g -C 3 N 4 Preparation of Mesoporous Composite Photocatalyst

[0042] 1. Preparation of g-C 3 N 4 catalyst of light

[0043] 1. Put melamine into an open crucible and heat at 2°C min -1 The heating rate is from room temperature to 550°C and kept for 4h.

[0044] 2. After cooling to room temperature, take out the yellow solid and grind it to powder with an agate mortar to obtain mesoporous g-C 3 N 4 catalyst of light.

[0045] 2. Preparation of 15wt% Fe 3 o 4 / g -C 3 N 4 Mesoporous Composite Photocatalyst

[0046] 1. Weigh 0.2625g of ferric chloride hexahydrate and dissolve it in 35mL of ethylene glycol and stir to obtain solution A.

[0047] 2. Add 3.6 g of sodium acetate to solution A to form solution B.

[0048] 3. Add 0.5g of g-C to solution B 3 N 4 , magnetically stirred for 12 h to form solution C.

[0049] 4. Transfer the solution C to a reaction kettle, and react in an oven at 200° C. for 6 hours.

[0050] 5. After n...

Embodiment 3

[0051] Example 3: 20wt% Fe 3 o 4 / g -C 3 N 4Mesoporous Composite Photocatalyst

[0052] 1. Preparation of g-C 3 N 4 catalyst of light

[0053] 1. Put melamine into an open crucible and heat at 2°C min -1 The heating rate is from room temperature to 550°C and kept for 4h.

[0054] 2. After cooling to room temperature, take out the yellow solid and grind it to powder with an agate mortar to obtain mesoporous g-C 3 N 4 catalyst of light.

[0055] 2. Preparation of 20wt% Fe 3 o 4 / g -C 3 N 4 Mesoporous Composite Photocatalyst

[0056] 1. Weigh 0.3501g of ferric chloride hexahydrate and dissolve it in 35mL of ethylene glycol and stir to obtain solution A.

[0057] 2. Add 3.6 g of sodium acetate to solution A to form solution B.

[0058] 3. Add 0.5g of g-C to solution B 3 N 4 , magnetically stirred for 12 h to form solution C.

[0059] 4. Transfer the solution C to a reaction kettle, and react in an oven at 200° C. for 6 hours.

[0060] 5. After naturally cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com