A kind of spider silk hydrolyzate and preparation method thereof

A technology for spider silk and hydrolyzate, which is applied in the field of spider silk hydrolyzate and its preparation, can solve the problems of harsh preparation conditions and low amino acid yield, and achieves the effects of simple operation, easy absorption and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

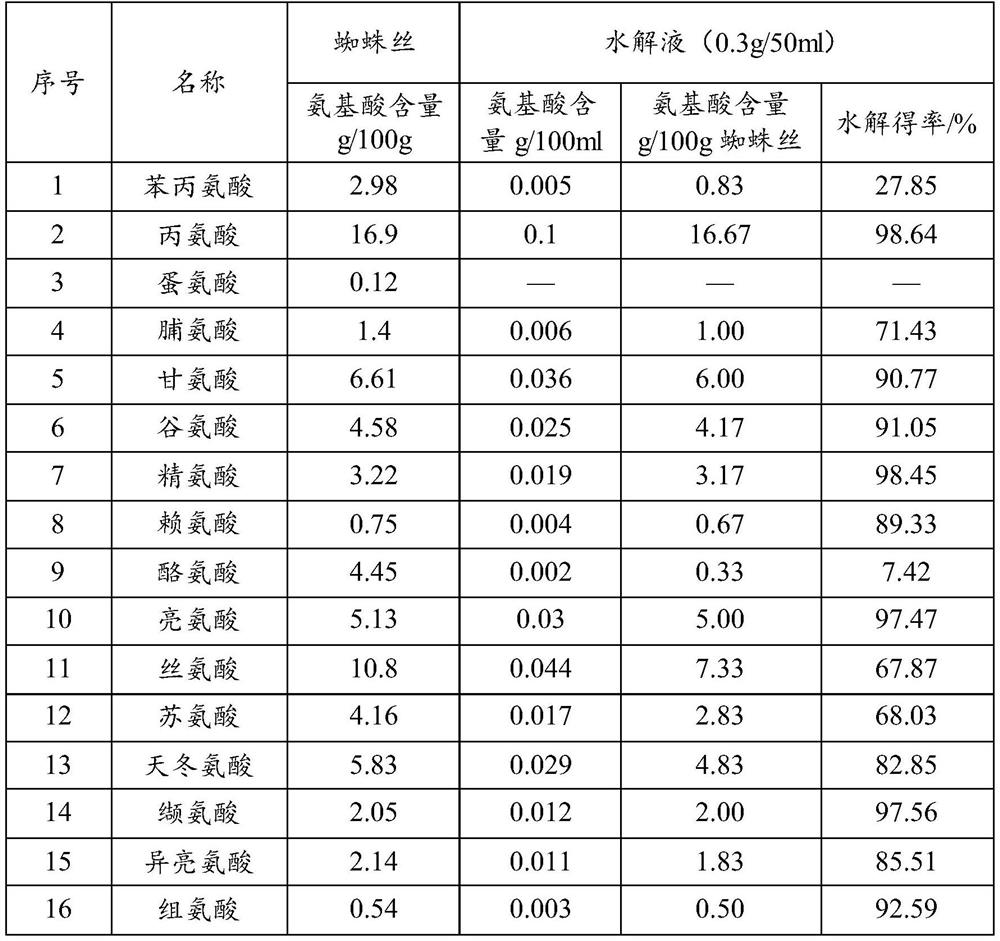

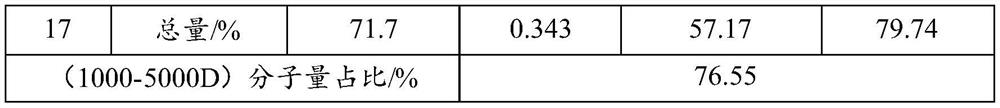

Image

Examples

Embodiment 1

[0049] The preparation of embodiment 1 spider silk hydrolyzate

[0050] The hydrolysis process of the present embodiment spider silk hydrolyzate is:

[0051] (1) Pretreatment: Take 2g of spider silk, rinse it with purified water to remove impurities, and put it in an agate ball mill for crushing until the spider silk has a flocculent or powdery growth length of <1 mm.

[0052] (2) Hydrolysis: Put the pulverized spider silk into a 1L glass container, add 200mL of 20g / L sodium hydroxide solution, and hydrolyze for 5h at a temperature of 80°C.

[0053] (3) Centrifugation: Centrifuge the hydrolyzate at a rotational speed of 15000r / min for 20min.

[0054] (4) Collection: Collect the centrifuged hydrolyzate into a glass container.

[0055] (5) Hydrolysis: hydrolyze the unhydrolyzed spider silk again, the method is the same as (2).

[0056] (6) Neutralization: neutralize with 1mol / L hydrochloric acid solution to pH 4.5.

[0057] (7) Filtration: filter the neutralized hydrolyzate ...

Embodiment 2

[0059] The preparation of embodiment 2 spider silk hydrolyzate

[0060] The hydrolysis process of the present embodiment spider silk hydrolyzate is:

[0061] (1) Pretreatment: Take 2g of spider silk, rinse it with purified water to remove impurities, and put it in an agate ball mill for crushing until the spider silk has a flocculent or powdery growth length of <1 mm.

[0062] (2) Hydrolysis: Put the pulverized spider silk into a 1L glass container, add 200mL of 15g / L sodium hydroxide solution, and hydrolyze for 4.5h at a temperature of 85°C.

[0063] (3) Centrifugation: Centrifuge the hydrolyzate at a rotational speed of 15000r / min for 20min.

[0064] (4) Collection: Collect the centrifuged hydrolyzate into a glass container.

[0065] (5) Hydrolysis: hydrolyze the unhydrolyzed spider silk again, the method is the same as (2).

[0066] (6) Neutralization: neutralize with 1mol / L hydrochloric acid solution to pH 5.0.

[0067] (7) Filtration: filter the neutralized hydrolyzate ...

Embodiment 3

[0069] Example 3 Preparation of spider silk hydrolyzate

[0070] The hydrolysis process of the present embodiment spider silk hydrolyzate is:

[0071] (1) Pretreatment: Take 2g of spider silk, rinse it with purified water to remove impurities, and put it in an agate ball mill for crushing until the spider silk has a flocculent or powdery growth length of <1 mm.

[0072] (2) Hydrolysis: Put the pulverized spider silk into a 1L glass container, add 200mL of 25g / L sodium hydroxide solution, and hydrolyze for 4 hours at a temperature of 90°C.

[0073] (3) Centrifugation: Centrifuge the hydrolyzate at a rotational speed of 15000r / min for 20min.

[0074] (4) Collection: Collect the centrifuged hydrolyzate into a glass container.

[0075] (5) Hydrolysis: hydrolyze the unhydrolyzed spider silk again, the method is the same as (2).

[0076] (6) Neutralization: neutralize with 1mol / L hydrochloric acid solution to pH 5.5.

[0077] (7) Filtration: filter the neutralized hydrolyzate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com