Preparation method of environment-friendly primer for solid wood furniture

An environmental protection and primer technology, applied in primers, rosin coatings and other directions, can solve problems such as polluted environment, allergic purpura, chromosome damage, etc., and achieve the effects of simple preparation method, improved adhesion and impact resistance, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

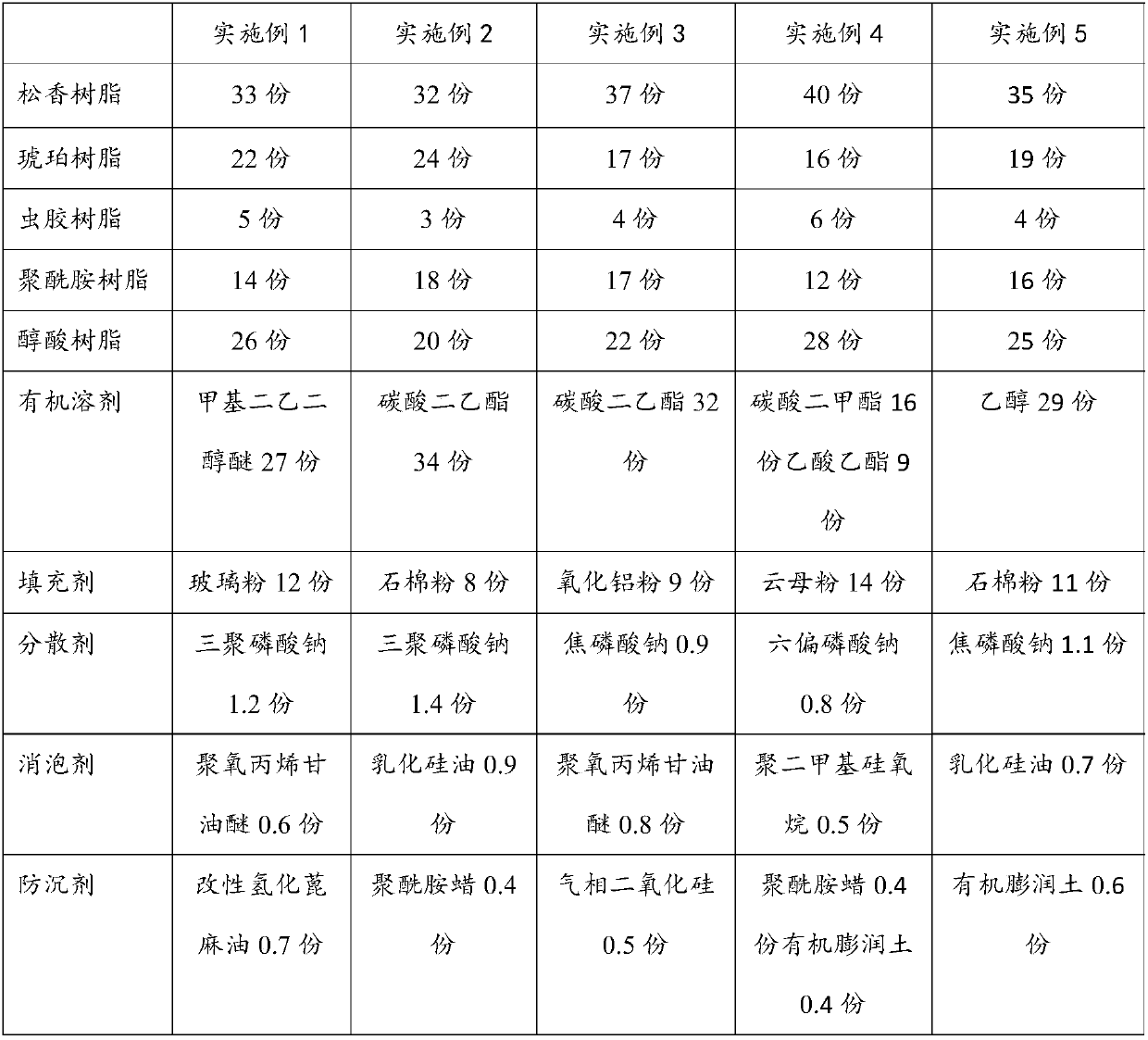

Examples

Embodiment 1

[0033] The preparation method of embodiment 1 solid wood furniture environmental protection primer is:

[0034] Accurately weigh the components of rosin resin, amber resin, shellac resin, polyamide resin, alkyd resin, methyl diethylene glycol ether, glass powder, sodium tripolyphosphate, polyoxypropylene glyceryl ether and modified hydrogenated castor sesame oil;

[0035] Add rosin resin, amber resin and shellac resin to the container filled with methyl diethylene glycol ether, start the stirrer, and the stirring speed is 380r / min, so that the rosin resin, amber resin and shellac resin are completely dissolved;

[0036] Add polyamide resin and alkyd resin to the container, add sodium tripolyphosphate at the same time, place it under microwave frequency of 1600MHz, and microwave for 8 minutes;

[0037] Add glass powder into the container, raise the temperature to 65°C, add polyoxypropylene glyceryl ether, raise the stirring speed to 400r / min, and keep the temperature for 50min...

Embodiment 2

[0040] The preparation method of embodiment 2 solid wood furniture environmental protection primer is:

[0041] Accurately weigh rosin resin, amber resin, shellac resin, polyamide resin, alkyd resin, diethyl carbonate, asbestos powder, sodium tripolyphosphate, emulsified silicone oil and polyamide wax;

[0042] Add rosin resin, amber resin and shellac resin to the container filled with diethyl carbonate, start the stirrer, and the stirring speed is 360r / min, so that the rosin resin, amber resin and shellac resin are completely dissolved;

[0043] Add polyamide resin and alkyd resin to the container, and add sodium tripolyphosphate at the same time, place it under the microwave frequency of 1900MHz, and microwave for 7 minutes;

[0044] Add asbestos powder into the container, raise the temperature to 73°C, add emulsified silicone oil, increase the stirring speed to 450r / min, and keep it warm for 35 minutes;

[0045] After the heat preservation reaction, add the polyamide wax i...

Embodiment 3

[0047] The preparation method of embodiment 3 solid wood furniture environmental protection primer is:

[0048] Accurately weigh the components of rosin resin, amber resin, shellac resin, polyamide resin, alkyd resin, diethyl carbonate, alumina powder, sodium pyrophosphate, polyoxypropylene glyceryl ether and fumed silica;

[0049] Add rosin resin, amber resin and shellac resin to the container filled with diethyl carbonate, start the stirrer, and the stirring speed is 280r / min, so that the rosin resin, amber resin and shellac resin are completely dissolved;

[0050] Add polyamide resin and alkyd resin to the container, add sodium pyrophosphate at the same time, place it under microwave frequency of 2000MHz, and microwave for 4 minutes;

[0051] Add alumina powder into the container, raise the temperature to 75°C, add polyoxypropylene glyceryl ether, raise the stirring speed to 600r / min, and keep the temperature for 30min;

[0052] After the heat preservation reaction, add fu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap