Polysulfone/natural fiber composite oil absorbing material and preparation method thereof

A technology of natural fibers and oil-absorbing materials, applied in the direction of plant fibers, etc., can solve the problems of polylactic acid temperature sensitivity, harsh processing conditions, and high material brittleness, and achieve the effects of fast absorption speed, easy processing and good oil absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

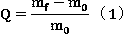

Method used

Image

Examples

Embodiment 1

[0027] Add 5 g of bisphenol A polysulfone into 50 mL of N-methylpyrrolidone, stir magnetically at room temperature for 5 h to fully dissolve; soak 1.5 g of croissant melon fiber in bisphenol A polysulfone solution, and swell for 30 min; After separation, immerse in distilled water, replace with stirring for 2 hours, and repeat 3 times; wash with water and ethanol in sequence, and dry at 20°C to obtain polysulfone / horn squash fiber composite oil-absorbing material. The absorption of soybean oil by the oil-absorbing material is 925% (the absorption of soybean oil by the polysulfone oil-absorbing material obtained without the addition of horn gourd fiber is 510%).

Embodiment 2

[0029] Add 1.5 g of polyethersulfone into 50 mL of dimethylacetamide, stir magnetically at room temperature for 15 h to fully dissolve; soak 1.5 g of chloroform-modified croissant melon fibers in the polyethersulfone solution, and swell for 10 min; After separation, submerged in tap water, replaced with stirring for 5 hours, repeated twice; washed with water and ethanol in sequence, and dried at 40°C to obtain polysulfone / croissia fiber composite oil-absorbing material. The oil-absorbing material has an absorption capacity of 818% for soybean oil.

Embodiment 3

[0031] Add 10 g of polyphenylsulfone to 50 mL of dimethyl sulfoxide, and stir magnetically at room temperature for 1 h; soak 0.5 g of squash fiber in the polyphenylsulfone solution and swell for 60 min; separate the fibers and immerse in the NaCl solution , replaced under stirring for 1 h, repeated 5 times; washed with water and ethanol in sequence, and dried at 60°C to obtain a polysulfone / horia gourd fiber composite oil-absorbing material. The absorption capacity of the oil-absorbing material to soybean oil is 1056%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com