Slot-nanometer flower composite capillary core structure and fabrication method thereof

A nano-flower and capillary core technology is applied in the field of heat transfer, which can solve the problems of early reaching of the heat transfer limit of a flat heat pipe, drying up of the evaporation area, and limiting heat transfer performance, etc., and achieving a simple and easy preparation method and good surface durability. , the effect of easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

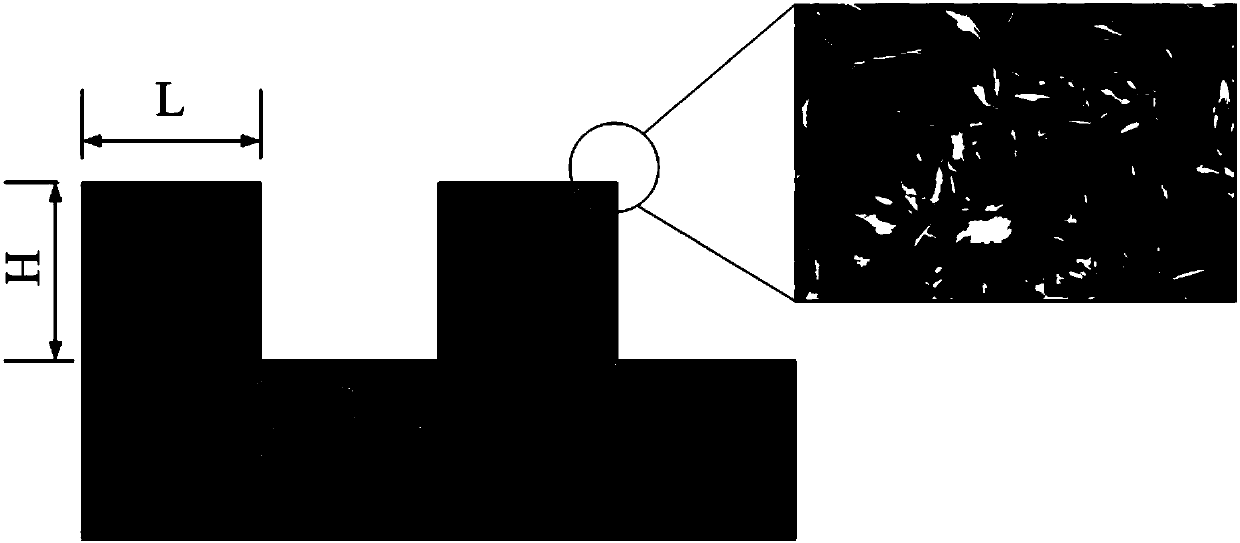

[0022] combine figure 1 , the capillary core of the composite structure of the present invention prepares a uniform nanoflower structure on the rectangular channel structure. The groove depth H, groove width D, and groove spacing L of the channel structure are all in the range of 0.3mm to 0.7mm, and the specific dimensions are adjusted according to the physical properties of the working fluid in the flat heat pipe. In the nanoflower structure, the thickness of the nanosheets is about 100 nm, the width of the nanosheets is 1 μm, and holes with a size of 1-2 μm are formed between the nanosheets.

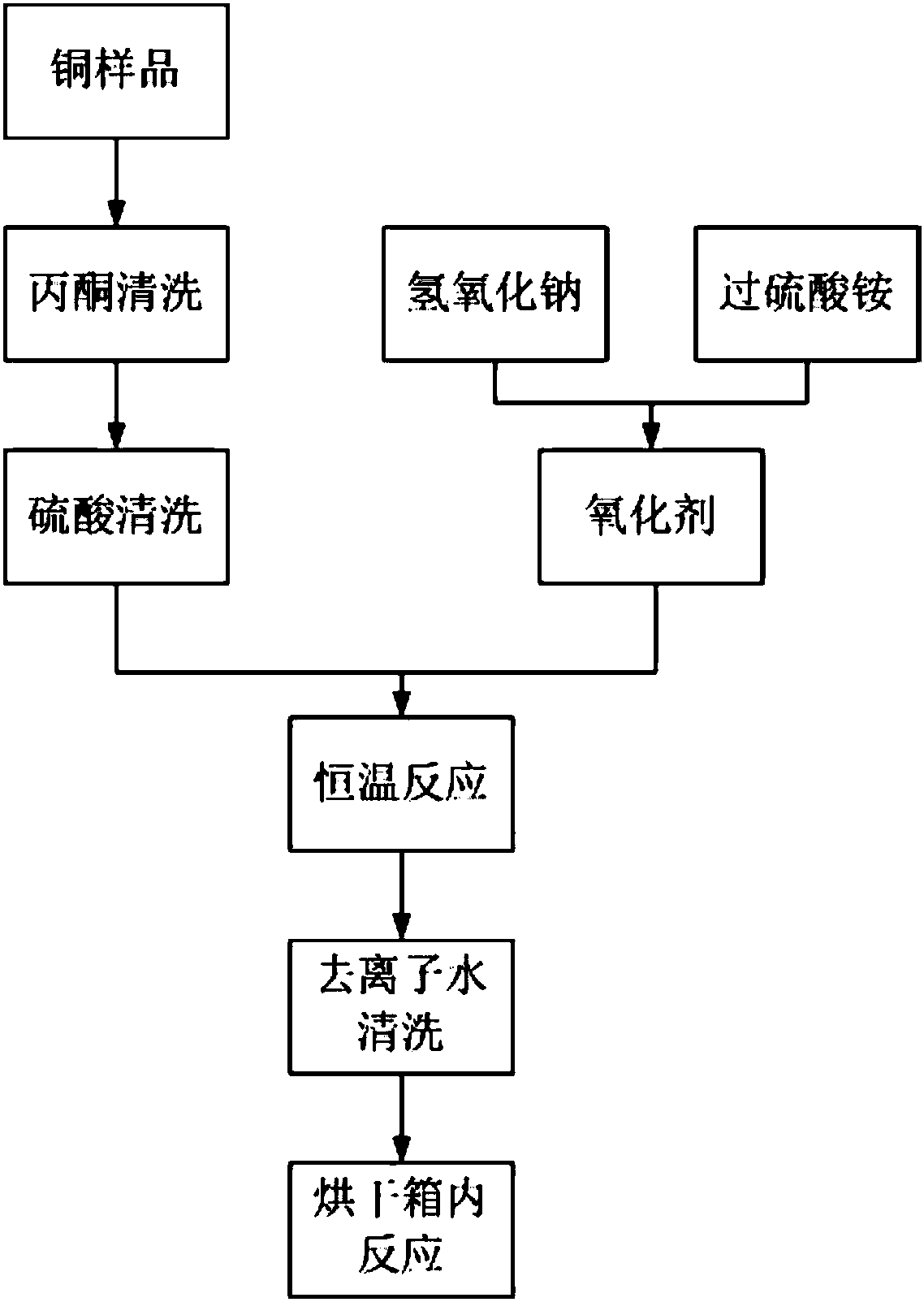

[0023] combine figure 2 , the method for preparing novel channel-nanoflower composite structure capillary core of the present invention, comprises the following steps:

[0024] In the first step, the copper sample is cut by wire, and channel structures of different sizes ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com