Submicron emulsion repairing stock solution composition and preparation method thereof as well as cosmetic composition containing submicron emulsion repairing stock solution composition

A technology of sub-microemulsion and composition, which is applied in the directions of cosmetics, cosmetic preparations, drug combinations, etc., can solve problems such as skin problems that cannot be fundamentally solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

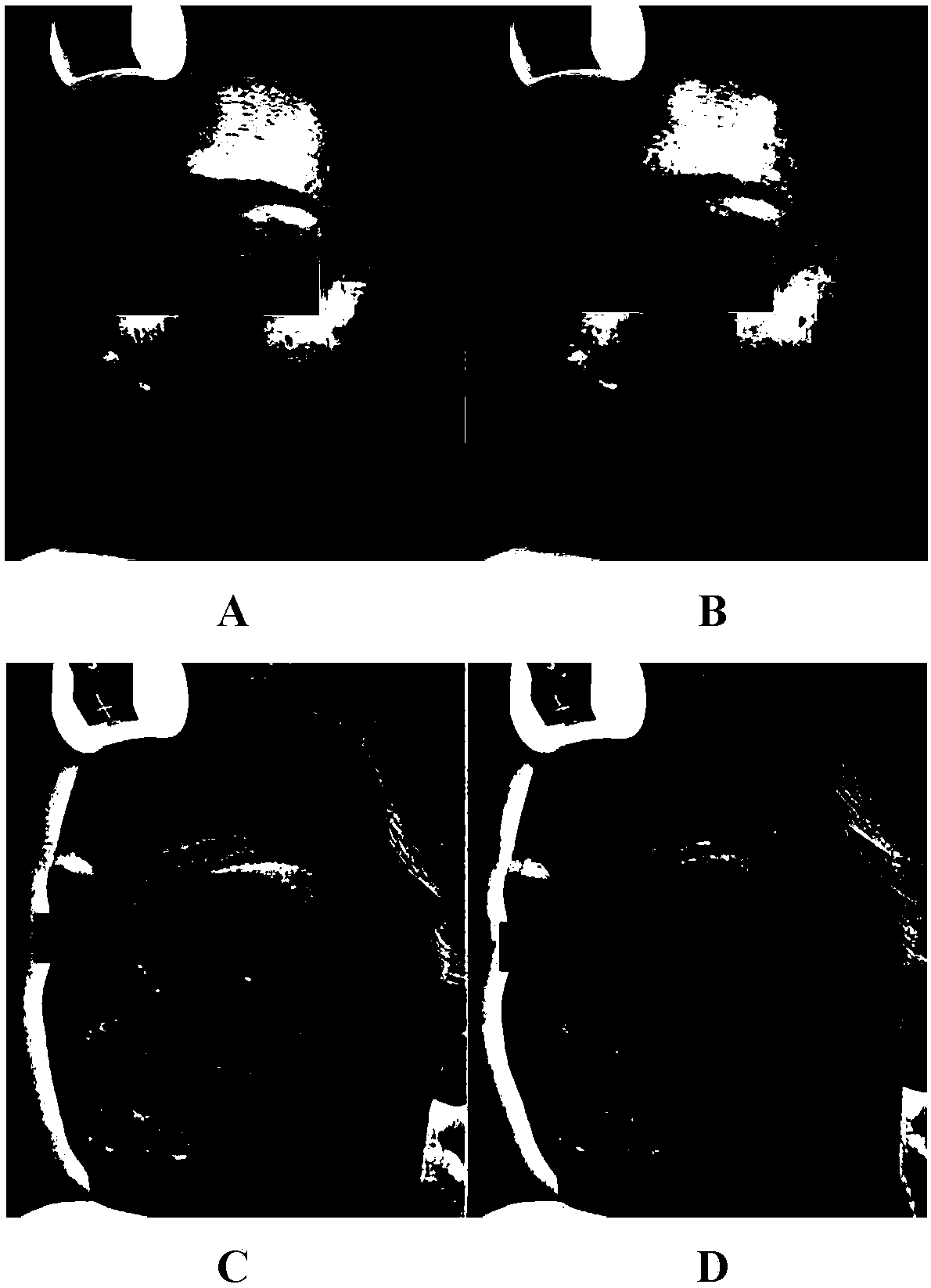

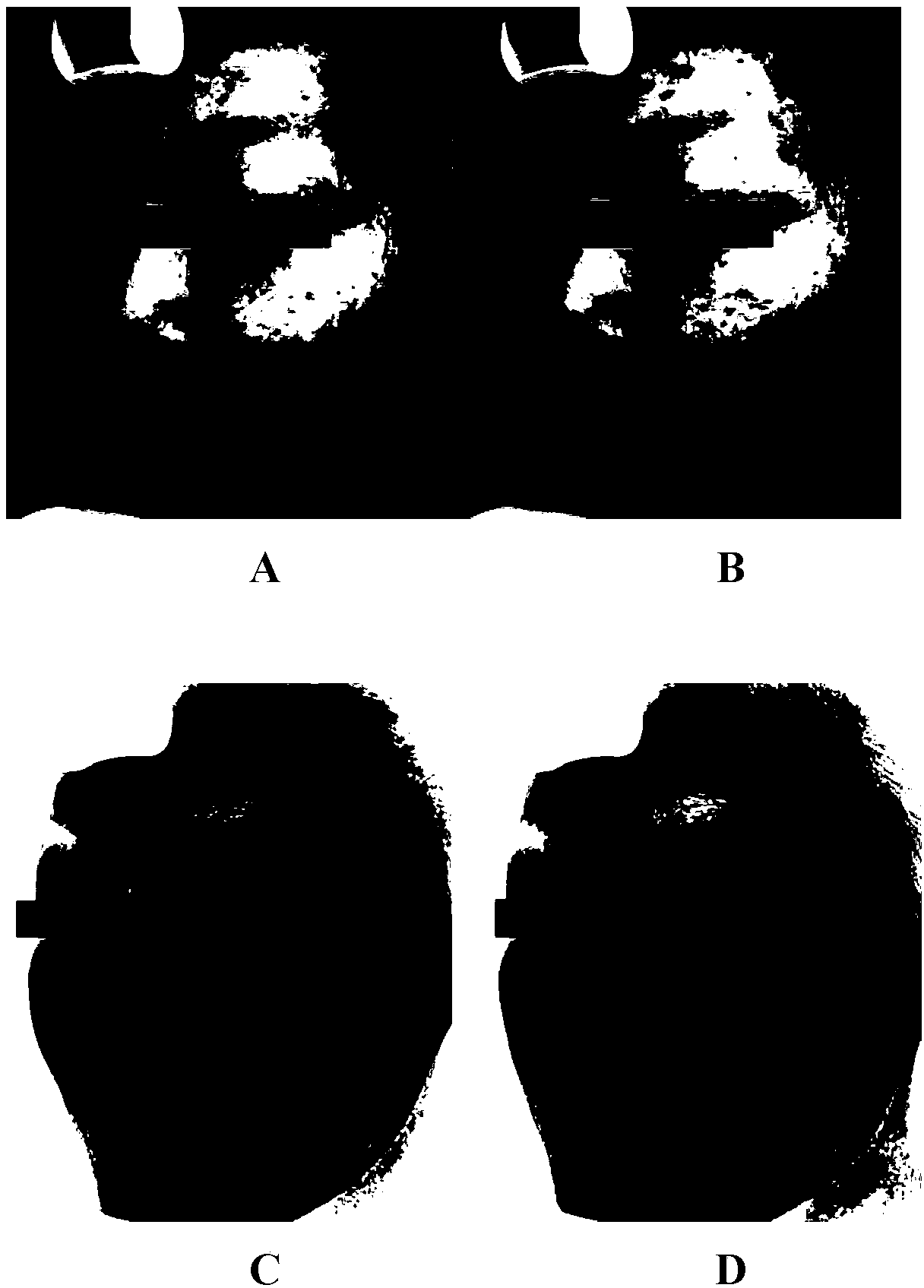

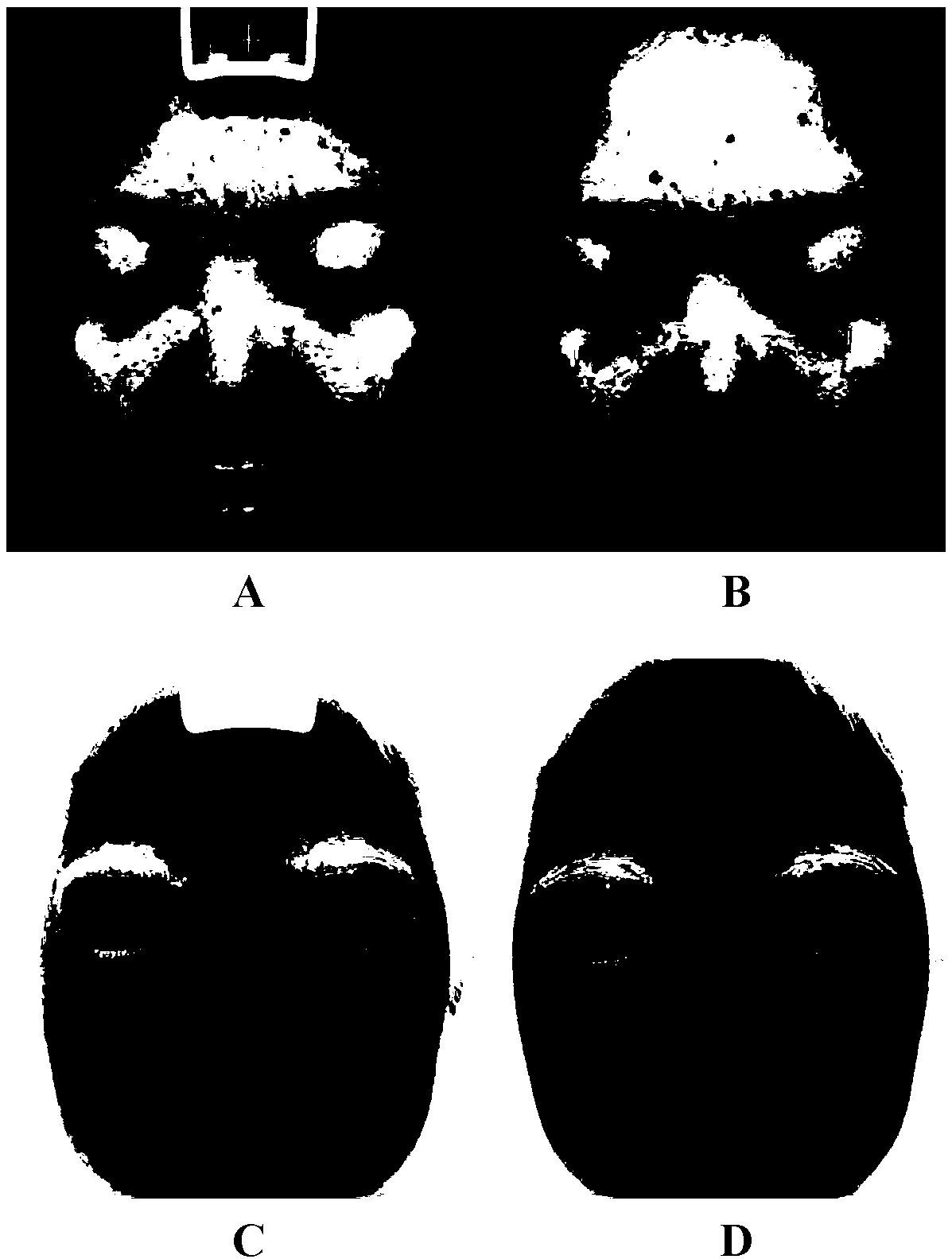

Image

Examples

Embodiment 1

[0078] Embodiment 1 A kind of preparation of submicron emulsion repair stock solution composition

[0079] The invention provides a method for preparing a submicron emulsion repair stock solution composition, the mass percentage of each component is as follows:

[0080]

[0081] Mix hyaluronic acid, hydroxyethylcellulose, propylene glycol / bis(hydroxymethyl)imidazolidinyl urea / methylparaben / iodopropynyl butylcarbamate with appropriate amount of ultrapure water in the prescribed amount Mix and dissolve in glycerin to obtain the water phase; mix mink oil, lecithin, and glyceryl monostearate, heat to 70°C, and cool to 40°C after completely dissolving to obtain the oil phase; stir at room temperature (300 rpm) to Add the water phase to the oil phase continuously at a rate of 0.5ml / min. After the emulsification is complete, add fatty alcohol polyoxyethylene ether and OSA modified starch dissolved in an appropriate amount of water, stir evenly, and obtain submicron Milk: Add olig...

Embodiment 2

[0085] Embodiment 2 Preparation of a kind of submicron emulsion repair stock solution composition

[0086] The invention provides a method for preparing a submicron emulsion repair stock solution composition, the mass percentage of each component is as follows:

[0087]

[0088]

[0089] Mix hyaluronic acid, DH-08, propylene glycol / bis(hydroxymethyl)imidazolidinyl urea / methylparaben / iodopropynyl butylcarbamate with appropriate amount of ultrapure water in glycerin in the prescribed amount Mix and dissolve to obtain a water phase; mix mink oil, soybean lecithin, and polysorbate, heat to 70°C, cool to 40°C after completely dissolving to obtain an oil phase; stir at room temperature (300 rpm) at 0.5ml / min Continuously add the water phase to the oil phase at a constant rate. After the emulsification is complete, add PEG-20, fatty alcohol polyoxyethylene ether and OSA modified starch dissolved in an appropriate amount of water. Stir evenly and obtain submicron Milk: Add olig...

Embodiment 3

[0091] Embodiment 3 Preparation of a kind of submicron emulsion repair stock solution composition

[0092] The invention provides a method for preparing a submicron emulsion repair stock solution composition, the mass percentage of each component is as follows:

[0093]

[0094]

[0095] Mix hyaluronic acid, hydroxyethyl cellulose, propylene glycol / bis(hydroxymethyl)imidazolidinyl urea / methylparaben / iodopropynyl butyl carbamate with appropriate amount of ultrapure water according to the prescribed amount Obtain the water phase; completely dissolve lecithin in ethanol, add isopropyl myristate and stir continuously on a magnetic stirrer until the system is fully uniform to obtain the oil phase; add the water phase to the oil phase under stirring conditions for emulsification The milky mixture is completely obtained, and then the oligopeptide-1, oligopeptide-3, and Cathelicidin-BF are mixed with the obtained milky mixture evenly and passed through a high-pressure micro-flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com