Manufacturing method of wood veneer and plastic composite interior wall decorative plate

A technology of wood veneer and manufacturing method, which is applied to the jointing of wooden veneers, manufacturing tools, wood processing appliances, etc., which can solve the problems of energy waste, inability to obtain high-quality wood-plastic composite interior wall decoration boards, and waste of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

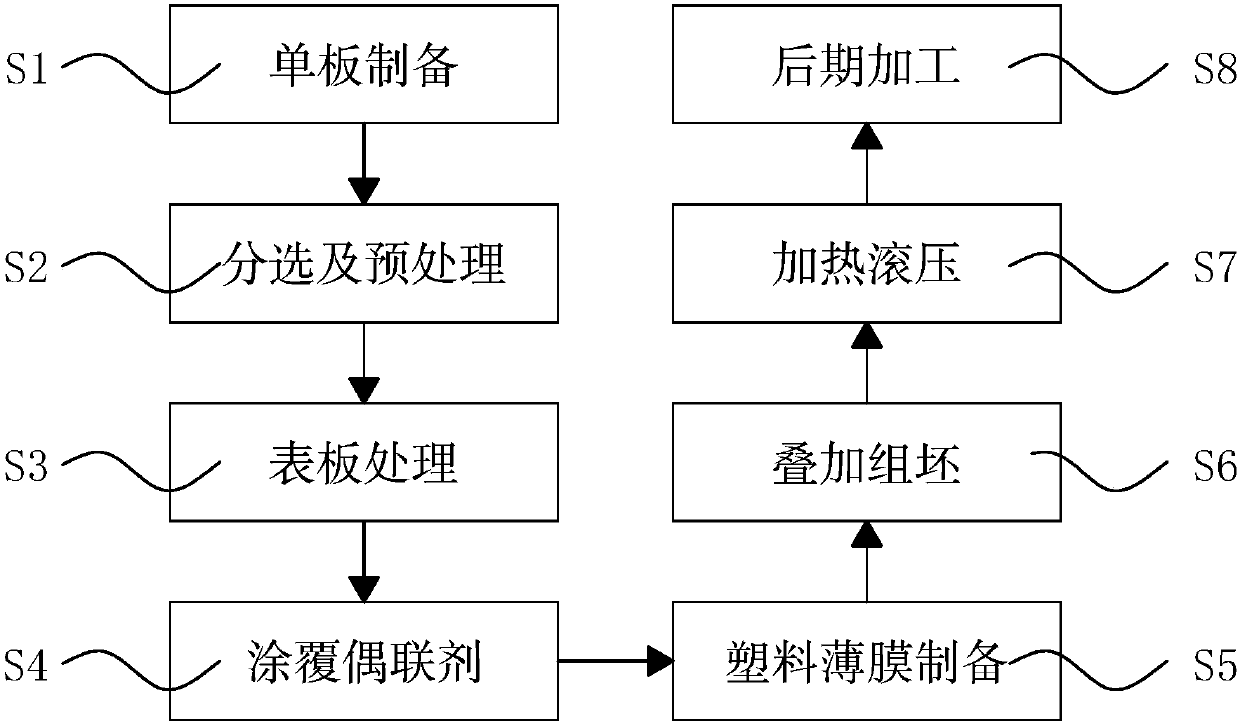

[0019] Embodiment 1: Combining figure 1 Illustrating this embodiment, a method for manufacturing a wood veneer-plastic composite interior wall decorative panel includes the following steps: S1, veneer preparation: processing the veneer to a thickness by rotary cutting or planing; sawing and cutting , cutting, planing, gluing, pressing or sewing in one or a combination of several methods to process the veneer with a fixed width; the thickness of the obtained veneer is 0.5mm ~ 5mm, and the width is 50mm ~ 900mm; S2, Sorting and pre-processing: Sort veneers according to their apparent quality, and select veneers with beautiful surfaces, no decay, no blue stain, no moth-eaten, and no flaws as the boards. The one with better quality is the outer surface; the other veneers are used as the core board; the veneer is pretreated, and the pretreatment is one or more of drying treatment and high temperature heat treatment; S3, surface plate treatment: the surface plate is treated Sanding...

specific Embodiment approach 2

[0021] Embodiment 2: Combining figure 1 Describing this embodiment, the method for manufacturing a wood veneer-plastic composite interior wall decorative panel described in this embodiment further includes the step of milling the edge of the slab cooled by the fixed thickness in step S8, and the edge Manual milling, vertical milling and / or double-end milling are used for partial milling, so that at least two long sides of the interior wall decorative panel have corresponding grooves and grooves;

[0022] The technical effect of this embodiment is: by using manual milling, end milling machine and / or double end milling, the interior wall decorative panels have grooves that can be matched with each other; , so that the manufactured interior wall decorative panel products can be directly put into use, which reduces manual intervention and processing errors, and can improve production efficiency; Compatible with each other and not deformed.

specific Embodiment approach 3

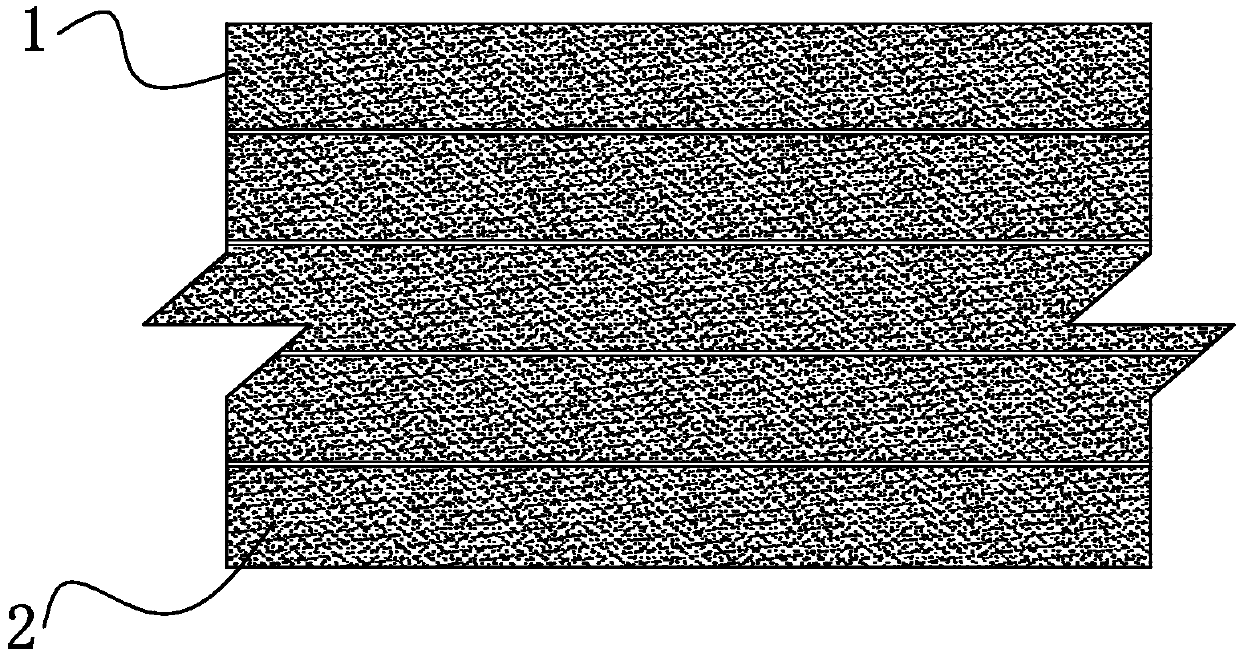

[0023] Embodiment 3: Combiningfigure 1 Illustrating this embodiment, a method for manufacturing a wood veneer-plastic composite interior wall decorative panel described in this embodiment, the obtained interior wall decorative panel is rectangular in plane, and its two long side sides and two short side sides are After milling, the two long side surfaces have corresponding grooves that match each other; the two short side surfaces also have corresponding grooves that match each other; the others are the same as in the specific embodiment 1 or 2.

[0024] The technical effect of this embodiment is: in order to facilitate the construction operation, the interior wall decorative panels used in interior decoration often need to be spliced to obtain a better decorative effect, and the matching grooves are beneficial to the splicing of the interior wall decorative panels. Reduce construction difficulty; grooves on both the long and short sides can not only help to extend the width ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com