Earlier-stage dispersion processing method for electrode raw materials of lithium ion battery

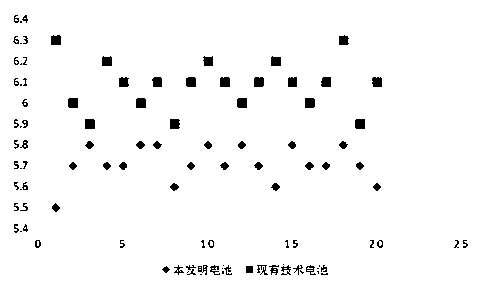

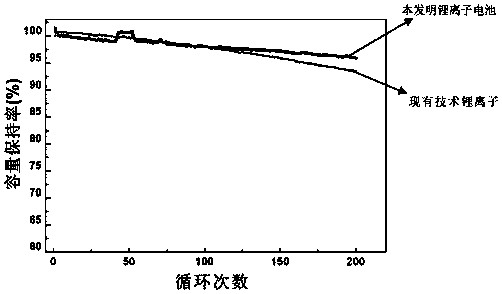

A lithium-ion battery, dispersion treatment technology, applied in the field of lithium-ion batteries, can solve the problems of re-agglomeration, general dispersion performance, battery capacity loss, etc., and achieve the effect of simple operation steps, good dispersion quality, and high-quality agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

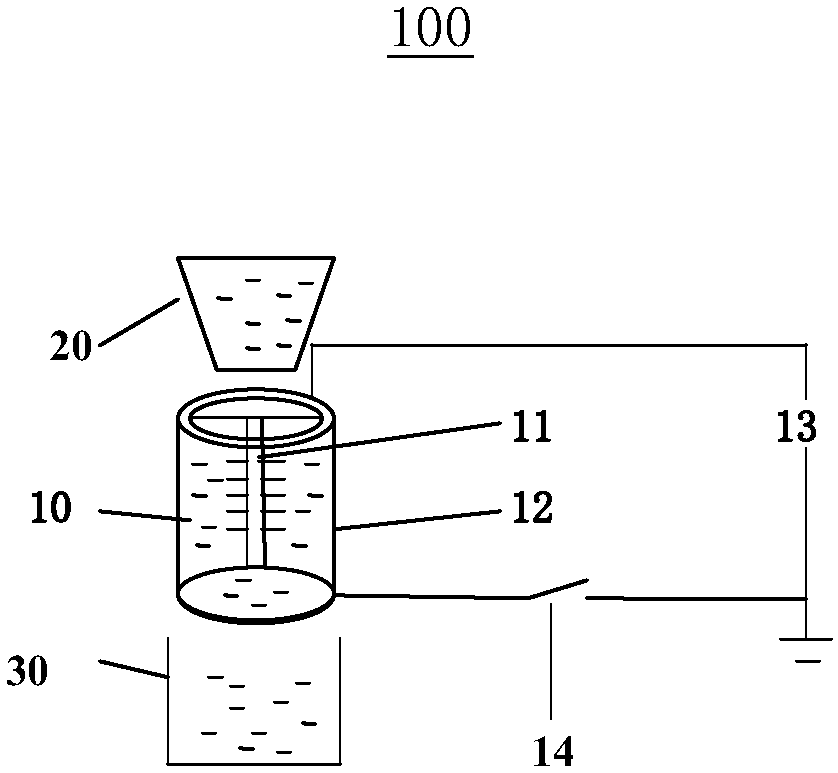

[0027] Embodiment 1, the early stage dispersion treatment method of lithium ion battery electrode raw materials of the present invention comprises the following steps:

[0028] (1) Weighing: Weigh a certain amount of LFP powder;

[0029] (2) Electrostatic dispersion: pass the weighed powder through a set of electrostatic dispersion device to charge the powder with the same charge: firstly, the above weighed powder is vibrated and dispersed by the feeder and then enters the electrostatic dispersion chamber. In this embodiment, the vibration frequency of the vibration motor used is 30 Hz; then the powder entering the electrostatic dispersion chamber is charged with the same charge by the charging device in the electrostatic dispersion chamber and then enters the powder collection chamber. During this process, The voltage of the adjustable high-voltage power supply is 10KV;

[0030] (3) Ingredients: the powder after electrostatic dispersion treatment, glue solution and NMP solve...

Embodiment example 2

[0033] Implementation case 2, the early stage dispersion treatment method of lithium ion battery electrode raw materials of the present invention comprises the following steps:

[0034] (1) Weighing: Weigh LFP powder, KS-6 powder and SP powder with a certain mass ratio;

[0035] (2) Electrostatic dispersion: Mix the weighed powders and pass a set of electrostatic dispersion device to charge the powders with the same charge: firstly, the weighed powders are vibrated and dispersed by the feeder and then enter the electrostatic dispersion bin , in this embodiment, the vibration frequency of the vibration motor used is 55Hz; then the powder entering the electrostatic dispersion chamber is charged with the same charge by the charging device in the electrostatic dispersion chamber and then enters the powder collection chamber. Among them, the voltage of the adjustable high-voltage power supply is 45KV;

[0036] (3) Ingredients: The powder after electrostatic dispersion treatment, p...

Embodiment 3

[0040] Embodiment 3, the early stage dispersion treatment method of lithium ion battery electrode raw materials of the present invention comprises the following steps:

[0041] (1) Weighing: Weigh KS-6 and SP powders according to a certain mass ratio;

[0042](2) Electrostatic dispersion: Mix the weighed powders and pass a set of electrostatic dispersion device to charge the powders with the same charge: firstly, the weighed powders are vibrated and dispersed by the feeder and then enter the electrostatic dispersion bin , in this embodiment, the vibration frequency of the vibration motor used is 80Hz; then the powder entering the electrostatic dispersion bin is charged with the same charge by the charging device in the electrostatic dispersion bin and then enters the powder collection bin. Among them, the voltage of the adjustable high-voltage power supply is 80KV;

[0043] (3) Ingredients: the powder after electrostatic dispersion treatment, glue solution and NMP solvent wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com