Electrolyte for secondary battery and preparation method thereof

A secondary battery and electrolyte technology, applied in the field of electrolyte, can solve the problems of long internal formation time, impervious formation, and poor uniformity of lead-acid batteries, achieve good battery capacity consistency, improve stability, and solve formation time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

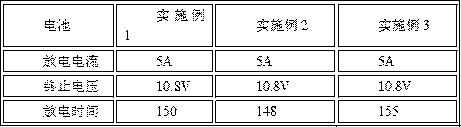

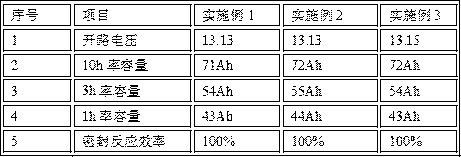

Embodiment 1

[0018] An electrolyte solution for a secondary battery, comprising the following raw materials in parts by weight: 25 parts of acid sulfate, 58 parts of solvent, and 8 parts of additives; Prepared by mixing at a ratio of 2:3; the solvent is water and maleic acid, tetrahydrofurfuryl alcohol, boric acid solution, porphyrin, acrylic acid, dibutyl carbonate, amyl acetate, polyvinylpyrrolidone iodine, triethyl phosphate , one or more compositions in water glass; the additive includes the following raw materials in parts by weight: 4 parts of lithium borate dioxalate, 1 part of ethylene sulfite, 2 parts of sodium chromate, carboxymethyl shell 2 parts polysaccharide, 3 parts sodium selenate, 2 parts potassium clavulanate.

[0019] A method for preparing an electrolyte solution for a secondary battery, comprising the following steps: (1) firstly weigh each raw material according to the above formula, and set aside; (2) then add acid sulfate and a solvent into the reaction kettle in se...

Embodiment 2

[0021] An electrolyte solution for a secondary battery, comprising the following raw materials in parts by weight: 32 parts of acid sulfate, 70 parts of solvent, and 11 parts of additives; the acid sulfate is composed of sodium bisulfate and potassium hydrogen sulfate Prepared by mixing at a ratio of 2:3; the solvent is water and maleic acid, tetrahydrofurfuryl alcohol, boric acid solution, porphyrin, acrylic acid, dibutyl carbonate, amyl acetate, polyvinylpyrrolidone iodine, triethyl phosphate , one or more compositions in water glass; the additive includes the following raw materials in parts by weight: 8 parts of lithium borate dioxalate, 3 parts of ethylene sulfite, 5 parts of sodium chromate, carboxymethyl shell 5 parts polysaccharide, 7 parts sodium selenate, 5 parts potassium clavulanate.

[0022] A method for preparing an electrolyte solution for a secondary battery, comprising the following steps: (1) First, weigh each raw material according to the above formula, and ...

Embodiment 3

[0024] An electrolyte solution for a secondary battery, comprising the following raw materials in parts by weight: 29 parts of acid sulfate, 62 parts of solvent, and 10 parts of additive; Prepared by mixing at a ratio of 2:3; the solvent is water and maleic acid, tetrahydrofurfuryl alcohol, boric acid solution, porphyrin, acrylic acid, dibutyl carbonate, amyl acetate, polyvinylpyrrolidone iodine, triethyl phosphate , one or more compositions in water glass; the additive includes the following raw materials in parts by weight: 6 parts of lithium borate dioxalate, 2 parts of ethylene sulfite, 2.5 parts of sodium chromate, carboxymethyl shell 3 parts polysaccharide, 4.6 parts sodium selenate, 3.1 parts potassium clavulanate.

[0025] A method for preparing an electrolyte solution for a secondary battery, comprising the following steps: (1) firstly weigh each raw material according to the above formula, and set aside; (2) then add acid sulfate and solvent into the reaction kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com