D-(-)-3-phosphoglycerate bonded silica gel grease adsorbent

A technology of phosphoglycerate and phosphoglycerate, which is applied in the field of D--3-phosphoglycerate bonded silica gel oil adsorbent, can solve the problems of reducing the taste and quality of oil, and achieve extended storage period and dosage. The effect of less and more selective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

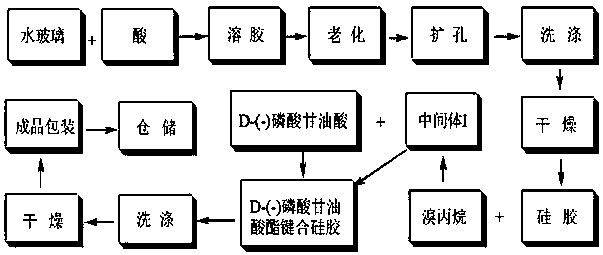

[0022] A D-(-)-3-phosphoglycerate bonded silica gel grease adsorbent, comprising the following steps:

[0023] (1) Using water glass and sulfuric acid as raw materials, silica gel is obtained through gelation, acidification treatment, aging, washing, pore expansion, and drying;

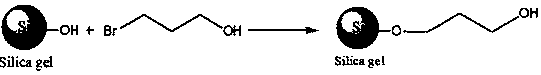

[0024] (2) Reaction of silica gel with 3-bromopropanol to obtain intermediate I: 4.1 g of silica gel prepared in step (1) was placed in a reaction kettle, and 2 mL of 3-bromo-propanol and 50-70 mL of isopropanol were added as solvents , add a catalyst with a mass of 0.01% of silica gel, heat, stir and reflux for 7 hours under the protection of nitrogen, wash with absolute ethanol after the reaction, and then dry to obtain intermediate I, which is 3-siloxane-1 - propanol;

[0025] The synthetic route is:

[0026]

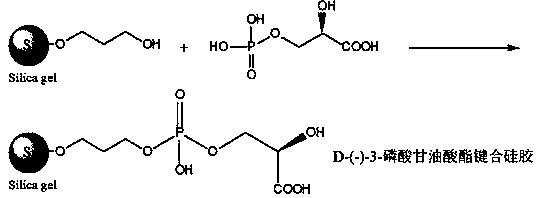

[0027] (3) Reaction of intermediate I with D-(-)-3-phosphoglycerate to obtain D-(-)-3-phosphoglycerate chiral molecular bonded grease silica gel: take 0.72g of D-(-)- 3-Phosphoglycerat...

Embodiment 2

[0038] A D-(-)-3-phosphoglycerate bonded silica gel grease adsorbent, comprising the following steps:

[0039] (1) Using water glass and sulfuric acid as raw materials, silica gel is obtained through gelation, acidification treatment, aging, washing, pore expansion, and drying;

[0040] (2) Reaction of silica gel with 3-bromopropanol to obtain intermediate I: 4.3 g of silica gel prepared in step (1) was placed in a reaction kettle, 4 mL of 3-bromo-propanol and 70 mL of isopropanol were added as solvents, and A catalyst with a mass of 0.03% silica gel was heated and stirred under the protection of nitrogen for 9 hours. After the reaction, it was washed with absolute ethanol, and then dried to obtain intermediate I, which was 3-siloxane-1-propane alcohol;

[0041] The synthetic route is:

[0042]

[0043] (3) Reaction of intermediate I with D-(-)-3-phosphoglycerate to obtain D-(-)-3-phosphoglycerate chiral molecular bonded grease silica gel: Take 0.74g of D-(-)- 3-Phosphogly...

Embodiment 3

[0054] A D-(-)-3-phosphoglycerate bonded silica gel grease adsorbent, comprising the following steps:

[0055] (1) Using water glass and sulfuric acid as raw materials, silica gel is obtained through gelation, acidification treatment, aging, washing, pore expansion, and drying;

[0056] (2) Reaction of silica gel with 3-bromopropanol to obtain intermediate I: 4.2 g of silica gel prepared in step (1) was placed in a reaction kettle, 3 mL of 3-bromo-propanol and 60 mL of isopropanol were added as solvents, and A catalyst with a mass of 0.02% silica gel was heated and stirred under the protection of nitrogen for 8 hours. After the reaction, it was washed with absolute ethanol, and then dried to obtain intermediate I, which was 3-siloxane-1-propane alcohol;

[0057] The synthetic route is:

[0058]

[0059] (3) Reaction of intermediate I with D-(-)-3-phosphoglycerate to obtain D-(-)-3-phosphoglycerate chiral molecular bonded grease silica gel: take 0.73g of D-(-)- 3-Phosphog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com