Method for preparing tributyrin

A technology of tributyrin and tributyric acid, which is applied in the field of tributyrin preparation, can solve the problems of poor catalyst selectivity and low reuse rate, and achieve high selectivity, low production cost and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

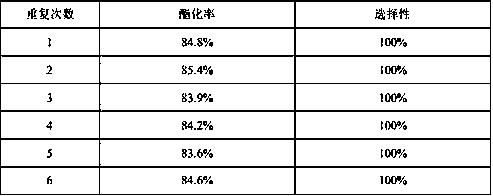

Examples

Embodiment 1

[0023] A kind of preparation method of tributyrin

[0024] First, 75.6g of butyric acid and 25.1g of glycerin were added to the reaction kettle in sequence, and after stirring was started, the reaction temperature was gradually increased to 110°C. Add 3 g of ionic liquid catalyst composed of α-pyrrolidone cation and hydrogen sulfate into the reaction kettle to carry out esterification reaction. After the esterification reaction, the reaction solution was statically stratified for 15 minutes, and the tributyrin product in the upper layer and the ionic liquid catalyst in the lower layer were separated and obtained. The obtained tributyrin product was sequentially washed three times with 3% sodium hydroxide solution in alkali and water, and then a feed grade tributyrin product with a conversion rate of 75.8%, a purity of 95.2%, and an acidity value of 3% could be obtained.

Embodiment 2

[0026] A kind of preparation method of tributyrin

[0027] First, 80g of butyric acid and 25g of glycerin were added to the reactor in sequence, and after stirring was started, the reaction temperature was gradually increased to 110°C. 5 g of ionic liquid catalyst composed of α-pyrrolidone cation and p-toluenesulfonate were added into the reaction kettle to carry out esterification reaction. After the esterification reaction, the reaction solution was statically stratified for 15 minutes, and the tributyrin product in the upper layer and the ionic liquid catalyst in the lower layer were separated and obtained. The obtained tributyrin product was sequentially washed with 3% sodium hydroxide solution in alkali and water for three times, and then a feed grade tributyrin product with a conversion rate of 84.8%, a purity of 96.8%, and an acidity value of 2.6% could be obtained.

Embodiment 3

[0029] A kind of preparation method of tributyrin

[0030] First, 78g of butyric acid and 25g of glycerin were added to the reactor in sequence, and after stirring was started, the reaction temperature was gradually increased to 110°C. Add 3 g of ionic liquid catalyst composed of α-pyrrolidone cation and dihydrogen phosphate into the reaction kettle to carry out esterification reaction. After the esterification reaction, the reaction solution was statically stratified for 15 minutes, and the tributyrin product in the upper layer and the ionic liquid catalyst in the lower layer were separated and obtained. The obtained tributyrin product was sequentially washed three times with 3% sodium hydroxide solution in alkali and water, and then a feed grade tributyrin product with a conversion rate of 72.6%, a purity of 92.4%, and an acidity value of 5.8% could be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com