High-temperature resistant sealant for inverted COBs (chip on board) and preparation method of high-temperature resistant sealant

A technology of high temperature resistance and encapsulation glue, which is applied in the direction of adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problems of easy hardening of encapsulation glue, poor high temperature resistance, easy cracking, etc., and achieve good high temperature resistance , Strong anti-yellowing property, less addition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

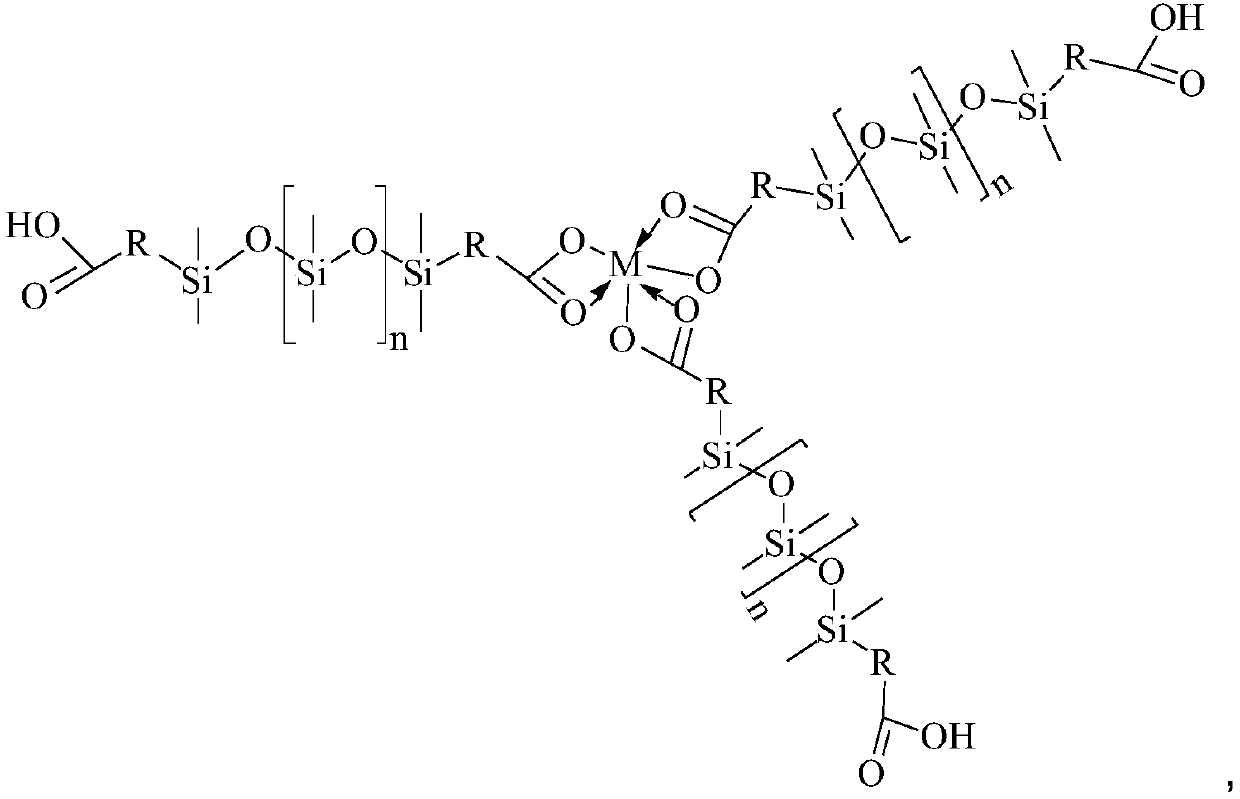

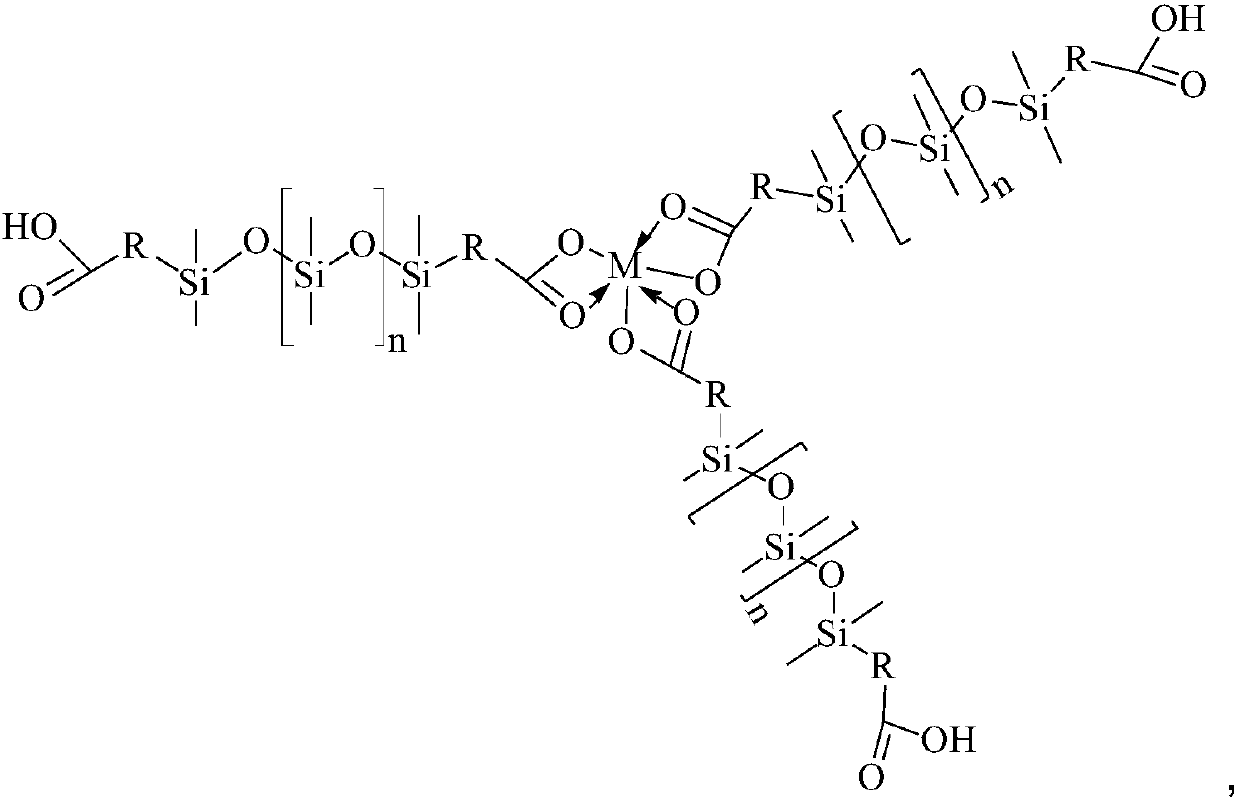

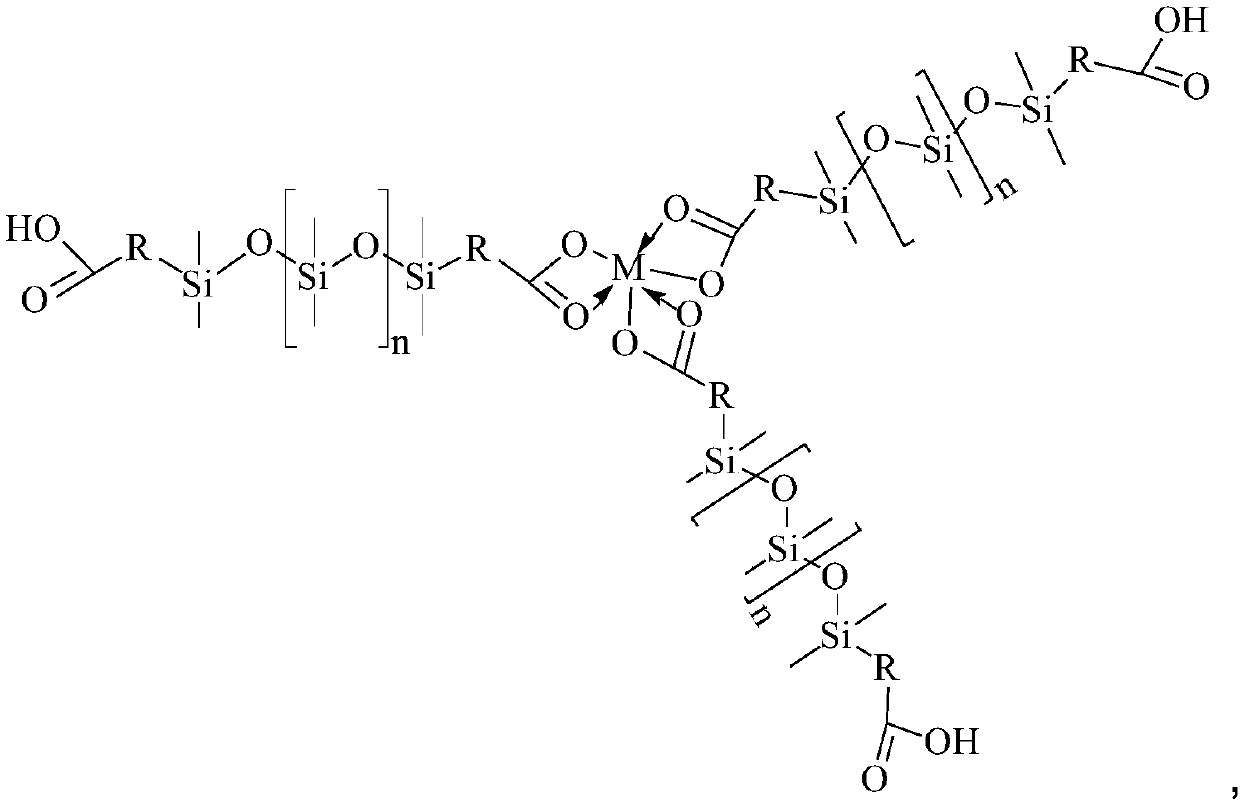

[0033] Example 1 Preparation of Lanthanum Metal Complex

[0034] The preparation method of the lanthanum metal complex comprises: adding 0.2212g lanthanum acetate and 30ml methanol in a three-neck flask (water bath) equipped with a constant pressure dropping funnel, stirring rapidly for 0.5h, slowly adding 0.3216g dicarboxysilane oil dropwise, Stir at 25 °C for 10 h. Rotary steam at 65°C under normal pressure to remove methanol until there is no boiling matter, add 30ml of ether and stir thoroughly, then filter with suction, and spin at 35°C until there is no boiling matter, and the lanthanum metal complex is obtained. The structural formula is:

[0035]

[0036] Where M is a lanthanide transition metal, R is -(CmH 2 m)-, m is an integer of 3-10; n is an integer of 5-30.

Embodiment 2

[0037] Example 2 High temperature resistant encapsulant for flip-chip COB

[0038] High-temperature-resistant encapsulant for flip-chip COB, including components A and B of equal mass; component A includes the following raw materials in parts by mass: 100 parts of vinyl silicone oil, 0.15 parts of platinum catalyst, 4 parts of tackifier, 1 part of thermal agent; component B includes the following raw materials in parts by mass: 60 parts of vinyl MQ silicone resin, 45 parts of crosslinking agent, and 0.05 parts of inhibitor. The vinyl content in vinyl silicone oil is 0.4%, the viscosity is 10000mPa·s, the M / Q of vinyl MQ silicone resin is 0.8, the vinyl content is 2.4%, and the platinum series catalyst is chloroplatinic acid-tetramethyldiethylene base disiloxane complex, the content of platinum is 4000ppm, the tackifier is γ-methacryloxypropyltrimethoxysilane, and the heat resistant agent is the lanthanum metal complex prepared in Example 1, The crosslinking agent is terminal ...

Embodiment 3

[0043] Example 3 High temperature resistant encapsulant for flip-chip COB

[0044] High-temperature-resistant encapsulant for flip-chip COB, including components A and B of equal mass; component A includes the following raw materials in parts by mass: 95 parts of vinyl silicone oil, 0.12 parts of platinum catalyst, 3 parts of tackifier, 0.8 parts of thermal agent; component B includes the following raw materials in parts by mass: 55 parts of vinyl MQ silicone resin, 44 parts of crosslinking agent, and 0.4 parts of inhibitor. The vinyl content in vinyl silicone oil is 0.3%, the viscosity is 20000mPa·s, the M / Q of vinyl MQ silicone resin is 0.8, the vinyl content is 2.4%, the platinum series catalyst is the alcohol solution of chloroplatinic acid, platinum The content is 5000ppm, the tackifier is vinyltrimethoxysilane, the heat-resistant agent is the lanthanum metal complex prepared in Example 1, the crosslinking agent is hydrogen-containing silicone oil at the terminal, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com