Concentrated combustion type in-situ thermal desorption repairing device for contaminated site

A technology of concentrated combustion and thermal desorption, which is applied in the restoration of polluted soil, grease/oily substance/suspton removal device, flotation water/sewage treatment, etc. issues of complex nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

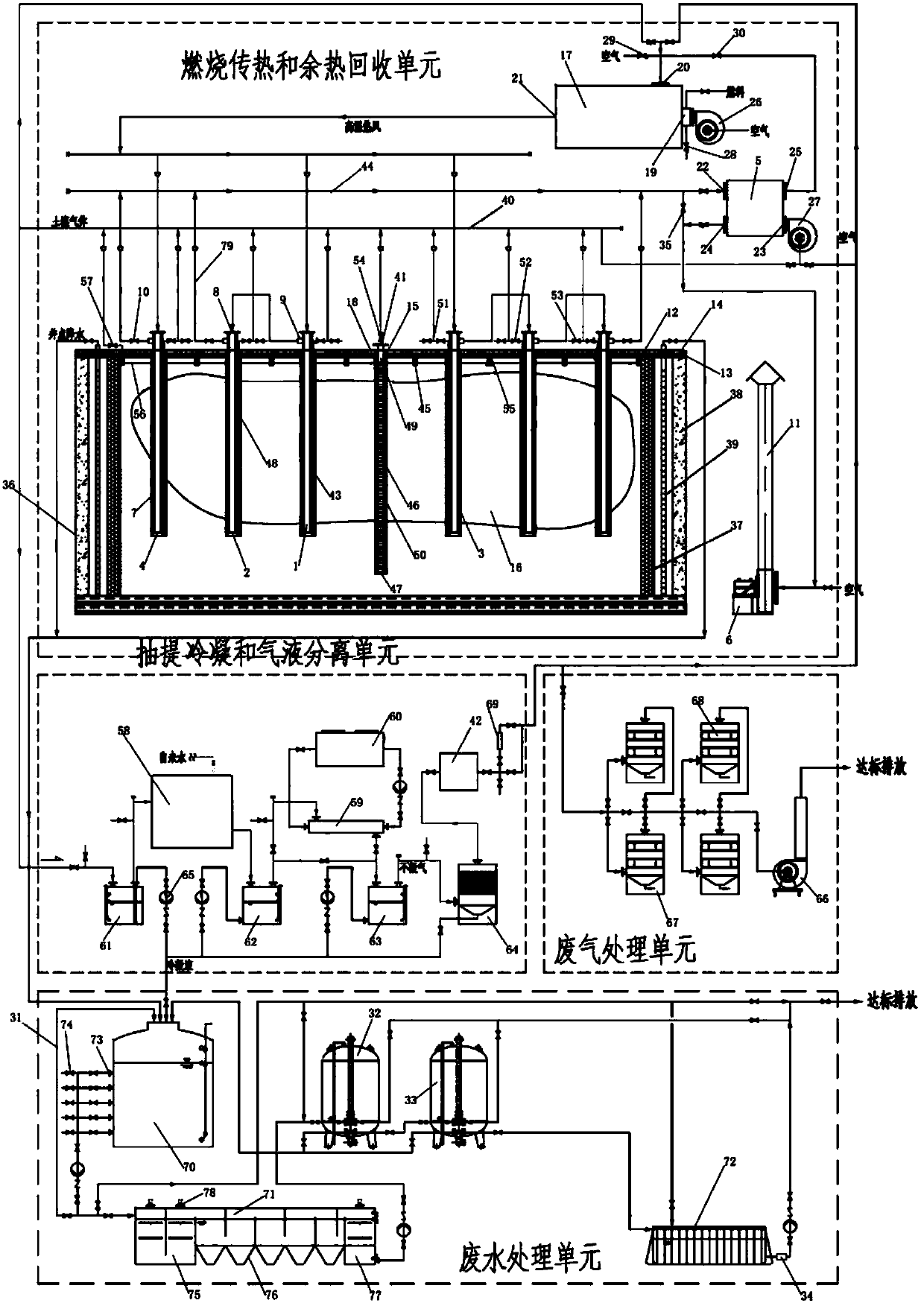

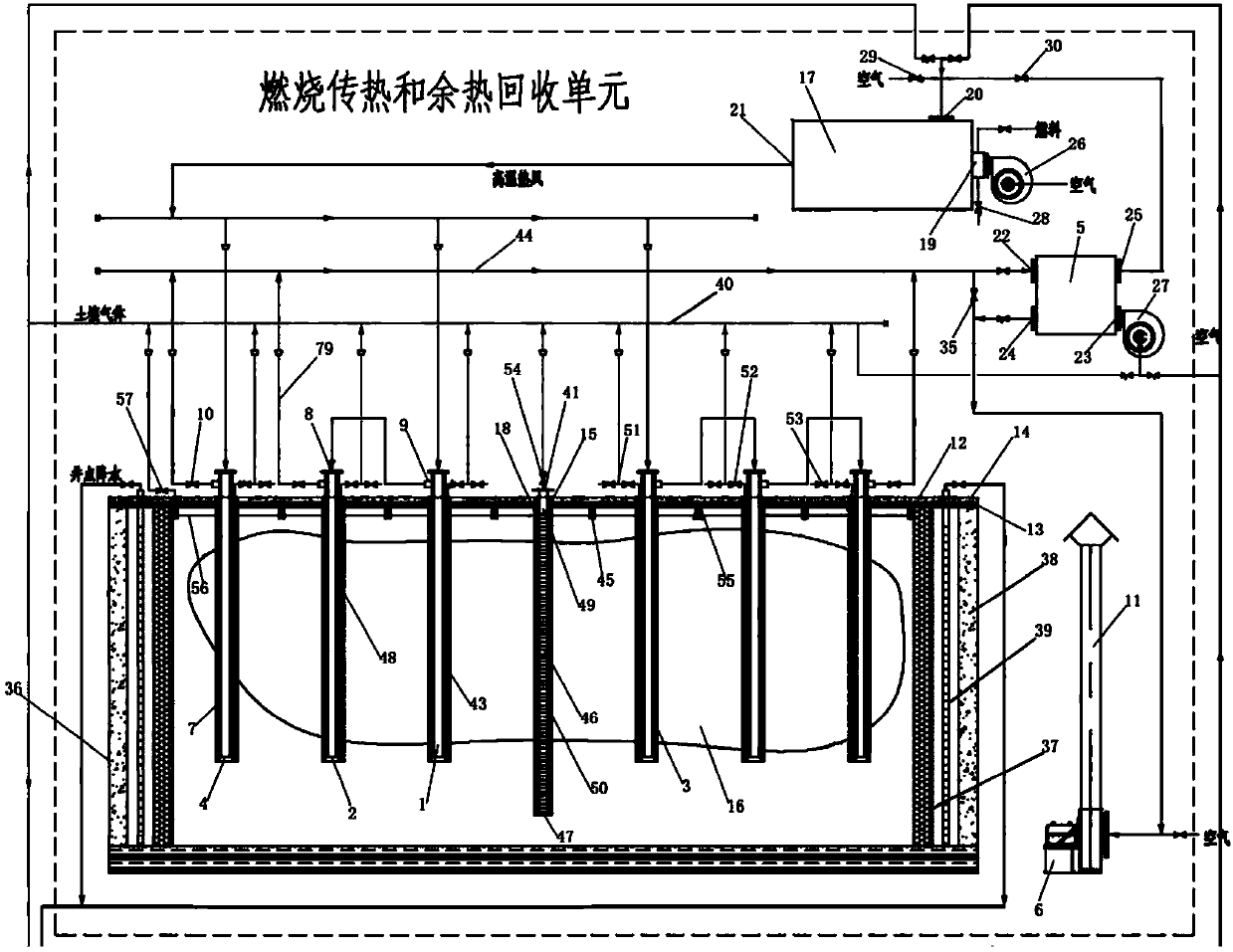

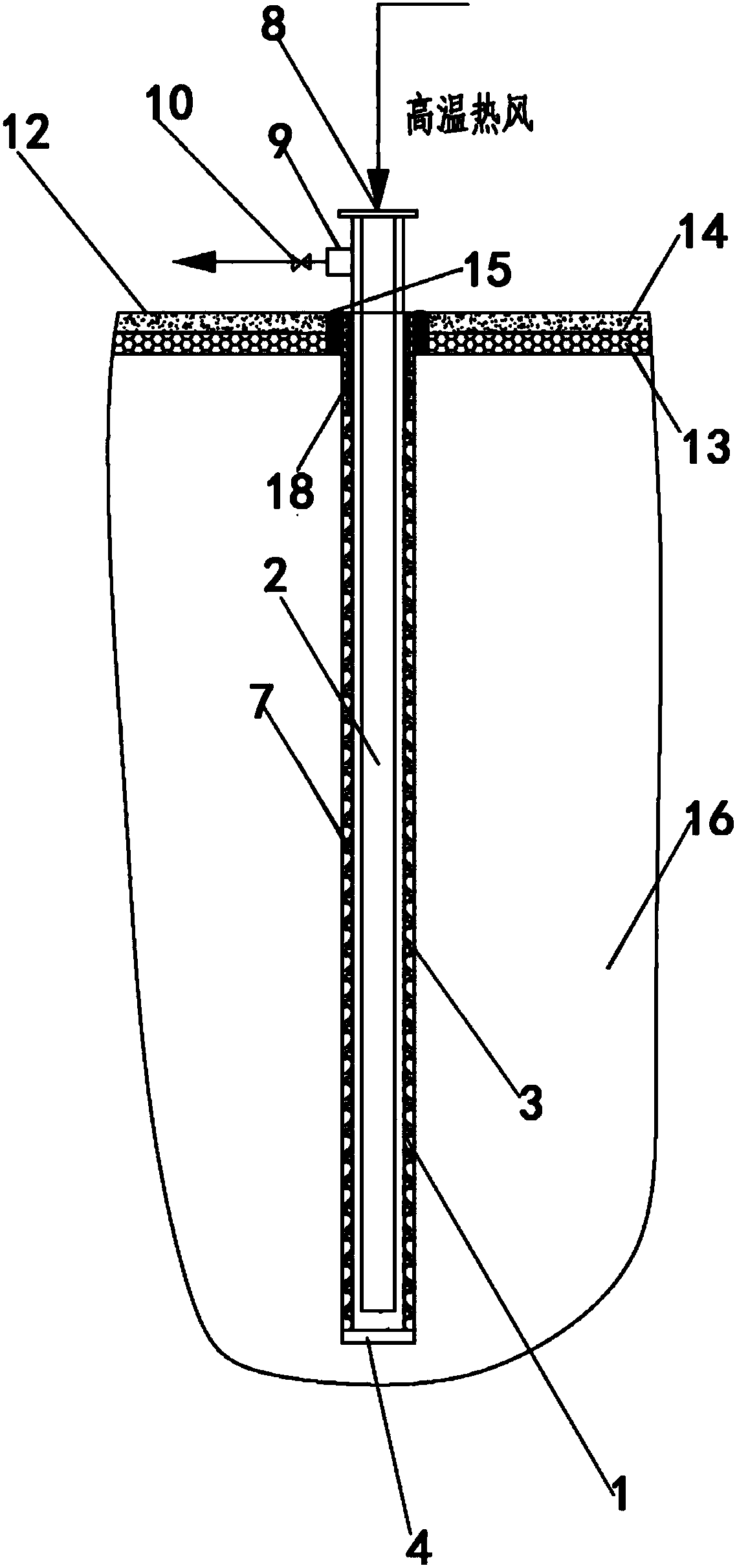

[0044] A centralized combustion in-situ thermal desorption repair device for polluted sites, including combustion heat transfer and waste heat recovery unit, extraction condensation and gas-liquid separation unit, groundwater flow control unit, soil gas control unit, waste gas treatment unit, waste water Processing units and pipelines. The combustion heat transfer and waste heat recovery unit includes a hot blast stove 17, an air-gas heat exchanger 5, a blower, an induced draft fan 6, an exhaust pipe 11, and a group of heating wells. The extraction condensing and gas-liquid separation unit includes extraction well group, heat exchange condensing equipment, gas-liquid separation equipment, demist tower 64 and vacuum pump 42; extraction well group includes several extraction well pipes 41, and extraction well pipe 41 includes vertical Some vertical well type extraction wells 43 installed in the polluted site, and some horizontal well type extraction wells 45 horizontally install...

Embodiment 2

[0064] A centralized combustion in-situ thermal desorption repair device for polluted sites, including combustion heat transfer and waste heat recovery unit, extraction condensation and gas-liquid separation unit, groundwater flow control unit, soil gas control unit, waste gas treatment unit, waste water Processing units and pipelines. The combustion heat transfer and waste heat recovery unit includes a hot blast stove 17, an air-gas heat exchanger 5, a blower, an induced draft fan 6, an exhaust pipe 11, and a group of heating wells. The extraction condensing and gas-liquid separation unit includes extraction well group, heat exchange condensing equipment, gas-liquid separation equipment, demist tower 64 and vacuum pump 42; extraction well group includes several extraction well pipes 41, and extraction well pipe 41 includes vertical Some vertical well type extraction wells 43 installed in the polluted site, and some horizontal well type extraction wells 45 horizontally install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com