Epoxidized soybean oil-based anti-mildew agent and preparation method and application thereof, and epoxidized decorative tile grout

A technology of epoxidized soybean oil and epoxidized soybeans, which is applied in the direction of botany equipment and methods, applications, biocides, etc., can solve the problems of easy migration and overflow of polymer materials, poor toughness of epoxy resin, and harm to human health, etc., to achieve Improve thermal shock and mold resistance, improve migration resistance, and toughen the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

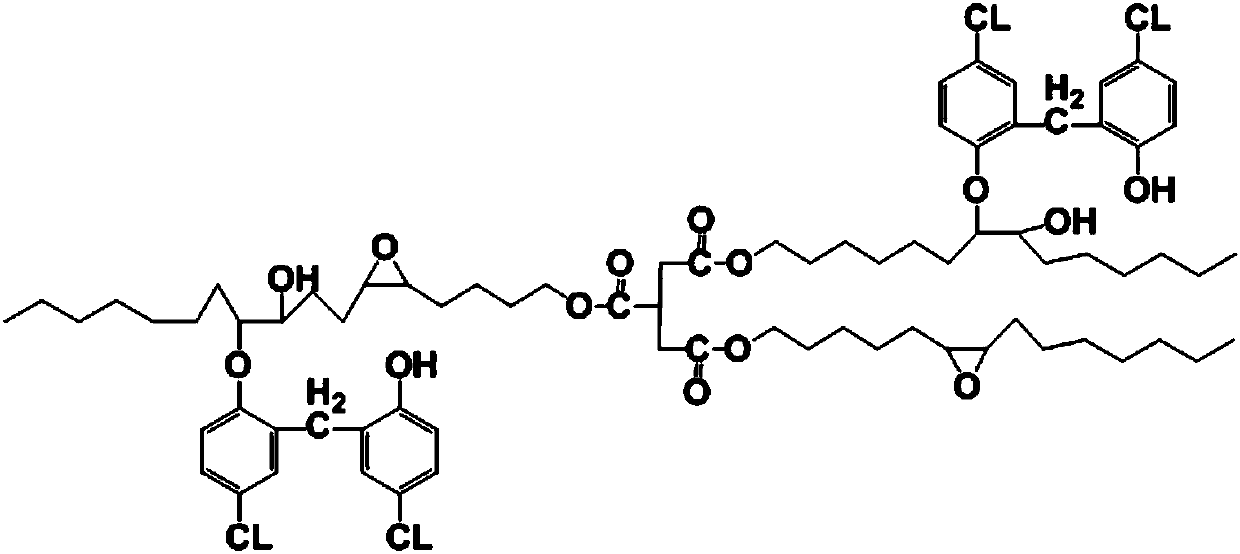

[0062] a. Add 100g epoxidized soybean oil into the reaction kettle with stirring device, condensation reflux device and liquid dripping device, and heat the oil bath to 80°C under the protection of nitrogen;

[0063] b, add 320g ethanol-diluted 2,2'-dihydroxy-5,5'-dichlorodiphenylmethane (concentration is 10wt%) in the reactor, the basic catalyst is KOH, the epoxy large The weight ratio of soybean oil to the basic catalyst is 1:0.05; after reacting at 90°C for 6 hours, the solvent is recovered under reduced pressure, cooled to room temperature and discharged to obtain the epoxy soybean oil-based antifungal agent.

[0064] The structure of gained epoxy soybean oil base fungicide is as follows:

[0065]

[0066] The carbon nuclear magnetic resonance spectrum of the soybean oil-based antifungal agent shows that: 158.1ppm is the displacement peak of the benzene ring carbon connected to the ether oxygen group, 67ppm is the displacement peak of the alkyl carbon connected to the h...

preparation example 2

[0068] a. Add 100g epoxidized soybean oil into the reaction kettle with stirring device, condensation reflux device and liquid dripping device, and heat the oil bath to 80°C under the protection of nitrogen;

[0069] b. Add 640g ethanol-diluted 2,2'-dihydroxy-5,5'-dichlorodiphenylmethane (concentration is 10wt%) in the reactor, basic catalyst KOH, the epoxidized soybean oil The weight ratio to the basic catalyst is 1:0.05; after reacting at 90°C for 6 hours, the solvent is recovered under reduced pressure, cooled to room temperature and discharged to obtain the epoxy soybean oil-based antifungal agent.

preparation example 3

[0071] a. Add 100g epoxidized soybean oil into the reaction kettle with stirring device, condensation reflux device and liquid dripping device, and heat the oil bath to 60°C under the protection of nitrogen;

[0072] b, add 320g ethanol-diluted 2,2'-dihydroxy-5,5'-dichlorodiphenylmethane (concentration is 10wt%) in the reactor, the basic catalyst is KOH, the epoxy large The weight ratio of soybean oil to the basic catalyst is 1:0.05; after reacting at 80°C for 6 hours, the solvent is recovered under reduced pressure, cooled to room temperature and discharged to obtain the epoxy soybean oil-based antifungal agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com