Coating process of automotive upholstery

A technology of automotive interior parts and coating technology, applied in the field of auto parts, can solve problems such as stability, self-thickening, insufficient solid content gloss retention, poor film forming and flexibility, poor water and solvent resistance, etc. , to achieve the effect of coating consumption, good hardness, excellent wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

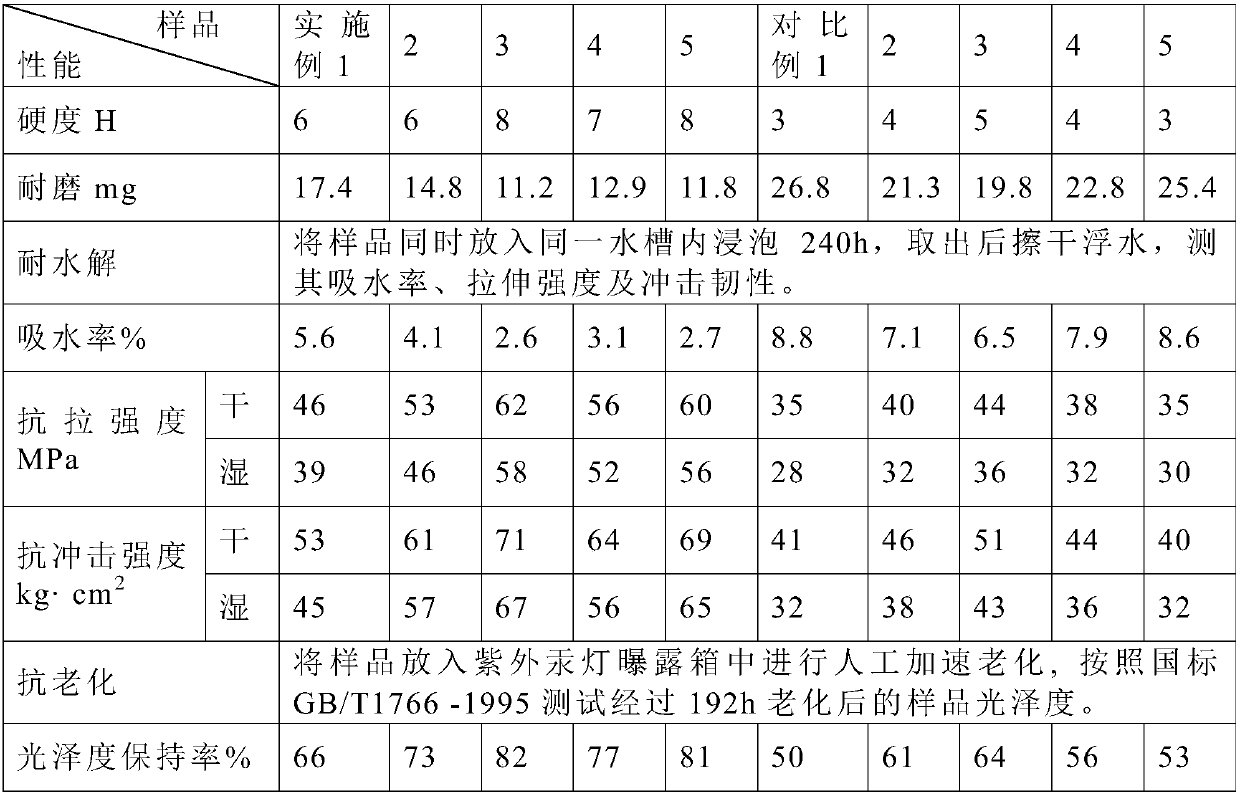

Examples

Embodiment 1

[0035] The coating material of the present embodiment is made up of the component of following parts by weight:

[0036] 16 parts of hydroxyacrylic acid emulsion; 55 parts of polystyrene grafted polyurethane; 12 parts of hydroxymethyl cellulose; 10 parts of cyclodextrin-coated calcium carbonate whiskers, 5 parts of diethylene glycol methyl ether; 12 parts of deionized water. The polystyrene segment accounts for 8% of the total amount of polystyrene-grafted polyurethane. The preparation method of cyclodextrin-coated calcium carbonate whiskers is as follows: disperse cyclodextrin in ethanol, stir at 5000r / min for 20min, then raise the temperature to 80°C, add filler, keep stirring at 500r / min, keep warm for 4h, filter and wash and drying to obtain cyclodextrin-coated calcium carbonate whiskers, wherein the mass ratio of cyclodextrin to calcium carbonate whiskers is 15:1.

[0037] Send the automotive interior parts to be processed into the spray booth. The temperature of the spr...

Embodiment 2

[0039] The coating material of the present embodiment is made up of the component of following parts by weight:

[0040] 16 parts of hydroxyacrylic acid emulsion; 55 parts of polystyrene grafted polyurethane; 12 parts of hydroxymethyl cellulose; 10 parts of cyclodextrin-coated calcium carbonate whiskers, 5 parts of diethylene glycol methyl ether; 12 parts of deionized water. The polystyrene segment accounts for 8% of the total amount of polystyrene-grafted polyurethane. The preparation method of cyclodextrin-coated calcium carbonate whiskers is as follows: disperse cyclodextrin in ethanol, stir at 5000r / min for 20min, then heat up to 80°C, add filler, keep stirring at 500r / min, keep warm for 4h, filter and wash and drying to obtain cyclodextrin-coated calcium carbonate whiskers, wherein the mass ratio of cyclodextrin to calcium carbonate whiskers is 15:1.

[0041] Send the automotive interior parts to be processed into the spray booth. The temperature of the spray booth is 25...

Embodiment 3

[0043] The coating material of the present embodiment is made up of the component of following parts by weight:

[0044]16 parts of hydroxyacrylic acid emulsion; 55 parts of polystyrene grafted polyurethane; 12 parts of hydroxymethyl cellulose; 10 parts of cyclodextrin-coated calcium carbonate whiskers, 5 parts of diethylene glycol methyl ether; 12 parts of deionized water. The polystyrene segment accounts for 8% of the total amount of polystyrene-grafted polyurethane. The preparation method of cyclodextrin-coated calcium carbonate whiskers is as follows: disperse cyclodextrin in ethanol, stir at 5000r / min for 20min, then heat up to 80°C, add filler, keep stirring at 500r / min, keep warm for 4h, filter and wash and drying to obtain cyclodextrin-coated calcium carbonate whiskers, wherein the mass ratio of cyclodextrin to calcium carbonate whiskers is 15:1.

[0045] Send the automotive interior parts to be processed into the spray booth. The temperature of the spray booth is 25°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com