Preparation method of copper/graphene composite material

A composite material and graphene technology, applied in the field of materials science, can solve the problems of poor graphene dispersion and interface bonding, and achieve the effects of low cost, convenient operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

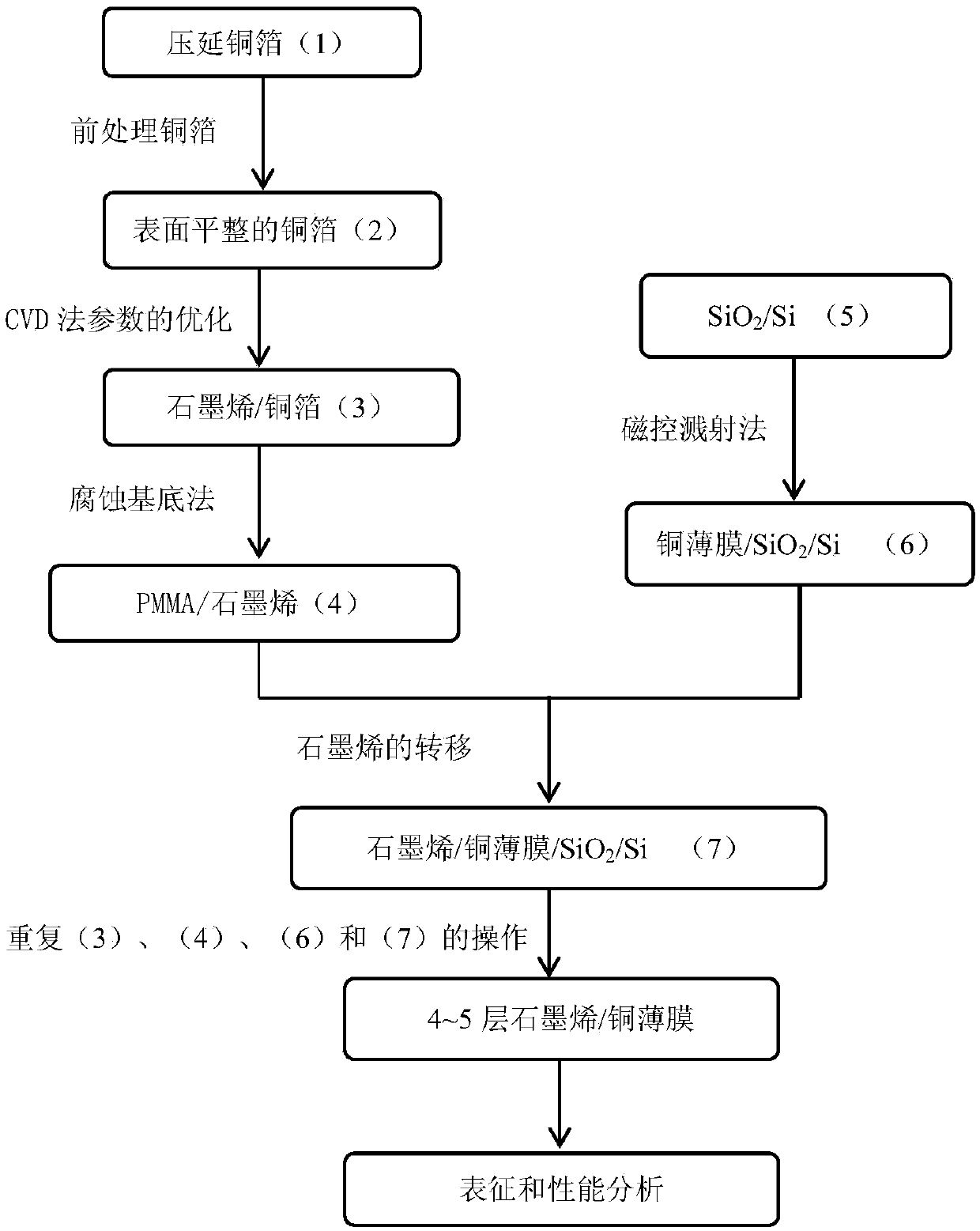

[0024] Such as figure 1 Shown, the invention provides a kind of preparation method of copper / graphene composite material,

[0025] Step 1: Use acetone, ethanol, and deionized water to ultrasonically clean the rolled copper foil with a size of 20mm*20mm*0.03mm for 10 minutes each, then use hydrochloric acid with a volume fraction of 25% to ultrasonically clean the copper foil for 10 minutes, and finally use ethanol Ultrasonic cleaning copper foil three times for 5 minutes each.

[0026] Step 2: Electrochemical polishing is an effective means to improve the quality of the metal surface. In this experiment, the copper foil treated in step 1 was polished. The electrochemical polishing power supply used is an electrochemical workstation, the polishing voltage is 10V, the polishing time is 40s, the sensitivity is selected as 1.0×e-0001, and the ratio of the polishing solution is deionized water: phosphoric acid: ethanol: isopropanol: urea =100mL:50mL:50mL:10mL:1g, the anode is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com