A large-scale graphene film with ultra-high conductivity and a radio frequency microwave device

A technology of graphene film and microwave devices, applied in the field of materials, can solve the problems of limited materials, insufficient conductivity, low conductivity, etc., and achieve the effect of large size, low contact resistance and low plane impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Preparation of flexible graphene film: Print graphene oxide film with a size of 20 μm, the printing thickness is 30 μm, and then undergo hot pressing at 100 ° C to obtain a graphene oxide film;

[0028] 2) Take the graphene oxide film prepared in step 1), put it in a graphite high-temperature furnace, undergo carbonization at 200-600°C and graphitization at a high temperature at 2000-3000°C, and finally further hot-press forming, the temperature of hot-pressing is 50 -200°C, made flexible graphene film;

[0029] 3) get the flexible graphene membrane sample that makes in step 2), test characteristics such as its electrical conductivity, resistivity and magnetic permeability, after measuring, the electrical conductivity of graphene membrane is 1 * 10 6 S / m;

[0030] 4) according to step step 3) the characteristics such as electrical conductivity, magnetic permeability of graphene film are measured, use electromagnetic simulation software design center frequency to be ...

Embodiment 2

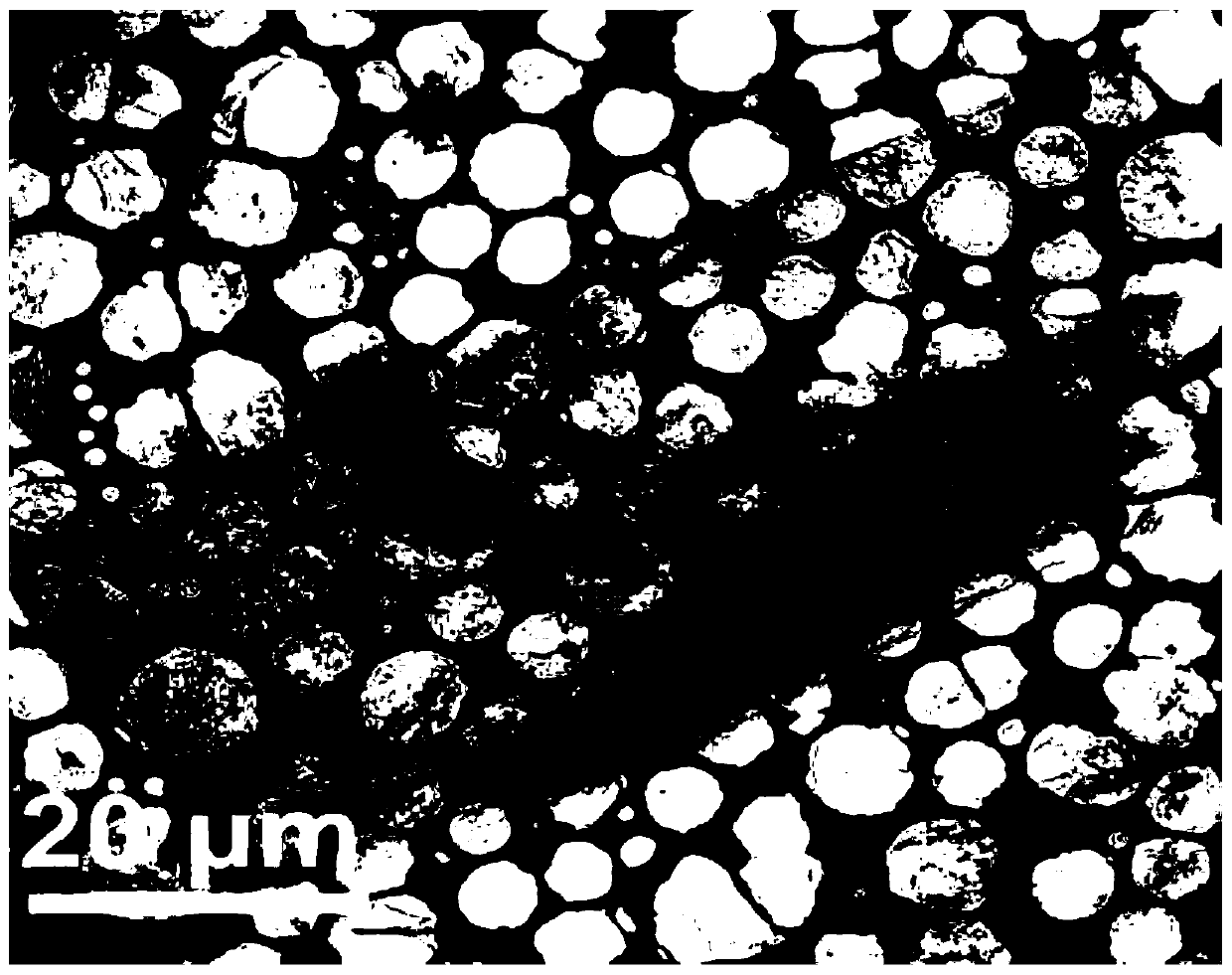

[0034] 1) Preparation of flexible graphene film: Graphene oxide film with a size of 60 μm is printed into a film with a printing thickness of 30 μm, and then hot-pressed at 100°C to obtain a graphene oxide film, and a graphene oxide sample is taken to observe its thickness with a transmission electron microscope. dimensions, the results are attached figure 2 As shown, the size of graphene oxide is 60-70 μm from the figure;

[0035] 2) Take the graphene oxide film prepared in step 1), put it in a graphite high-temperature furnace, undergo carbonization at 200-600°C and graphitization at a high temperature at 2000-3000°C, and finally further hot-press forming, the temperature of hot-pressing is 50 -200°C, made flexible graphene film;

[0036] 3) get the flexible graphene membrane sample that makes in step 2), test characteristics such as its electrical conductivity, resistivity and magnetic permeability, after measuring, the electrical conductivity of graphene membrane is 3.3 ...

Embodiment 3

[0041] 1) Preparation of flexible graphene film: Print a large-scale graphene oxide film with a size of 100 μm, the printing thickness is 30 μm, and then undergo hot pressing at 100 ° C to obtain a large-scale graphene oxide film;

[0042]2) Take the graphene oxide film prepared in step 1), put it in a graphite high-temperature furnace, undergo carbonization at 200-600°C and graphitization at a high temperature at 2000-3000°C, and finally further hot-press forming, the temperature of hot-pressing is 50 -200℃, a large size flexible graphene film was prepared, as attached figure 1 shown;

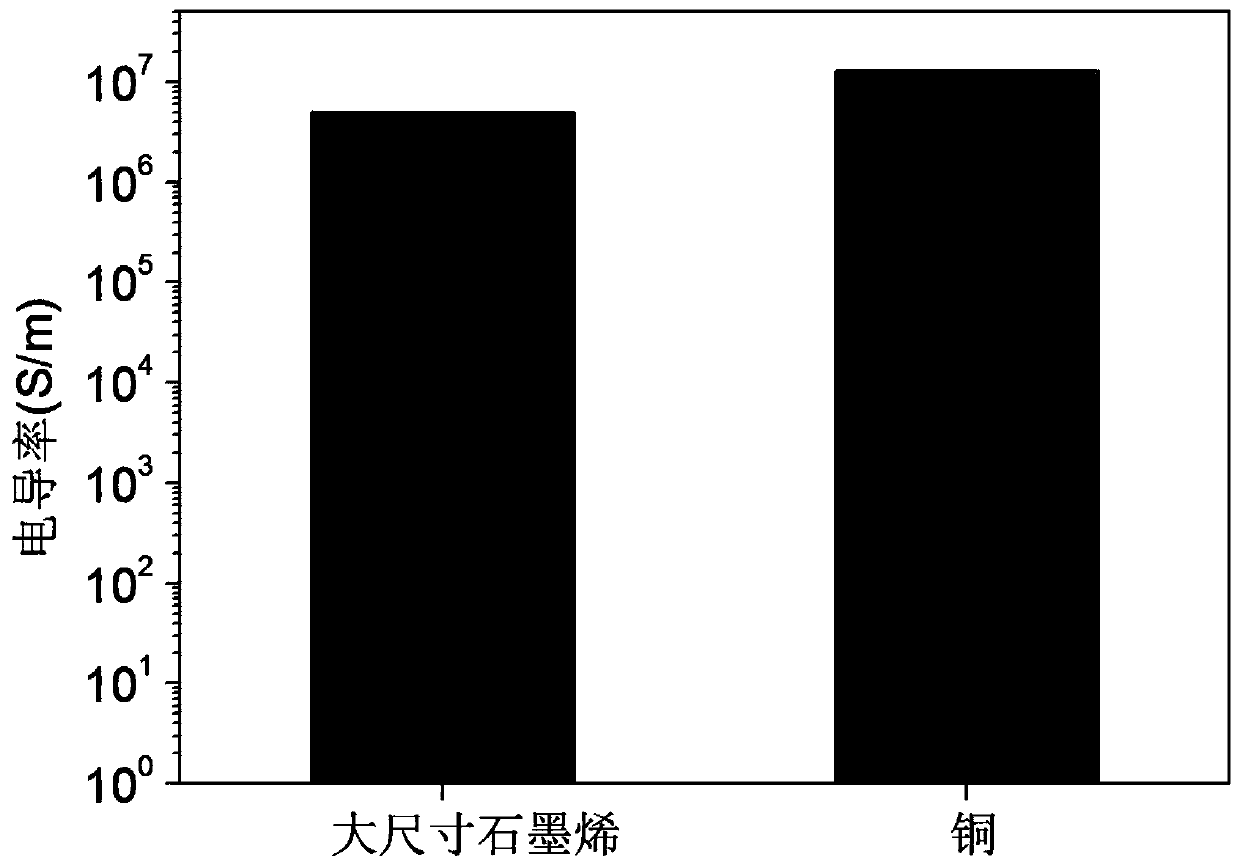

[0043] 3) Get the flexible graphene membrane sample that makes in step 2), test characteristics such as its electrical conductivity, electrical resistivity and magnetic permeability, large-scale graphene and copper electrical conductivity contrast figure as attached image 3 As shown, it can be seen from the figure that the conductivity of large-scale graphene is 5 × 10 6 S / m, similar to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com