ZnFe2O4 nitrogen-doped nanometer fiber composite electrode material and preparation method thereof

A technology of nanofibers and composite electrodes, which is applied in the field of ZnFe2O4 nitrogen-doped carbon nanofiber composite electrode materials and its preparation, can solve the problems that the preparation technology of nitrogen-doped carbon nanofiber composite electrode materials has not been reported, etc., to improve the electrochemical performance, The process is simple, the effect of increasing conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add ferric chloride, zinc acetate, and polyacrylonitrile in a molar ratio of 2:1 to 10 mL of dimethylformamide solution in sequence, the weight percentage of polyacrylonitrile in dimethylformamide is 10%, and iron salt The concentration in dimethylformamide is 0.05mol / L. The homogeneously mixed precursor solution was filled into a syringe with a metal needle with a diameter of 0.2 mm. Then, spinning was carried out under the conditions of electrospinning at a voltage of 10 kV, a bolus injection speed of 0.5 mL / min, and a distance of 10 cm between the needle and the receiver to obtain ZnFe 2 o 4 Precursors of nitrogen-doped carbon nanofibers. Finally, the obtained precursor was heated to 250 °C in air for 4 h, heated to 800 °C in argon, carbonized for 2 h, and heated to 250 °C in air for 4 h to obtain ZnFe 2 o 4 Nitrogen-doped carbon nanofiber composite electrode material.

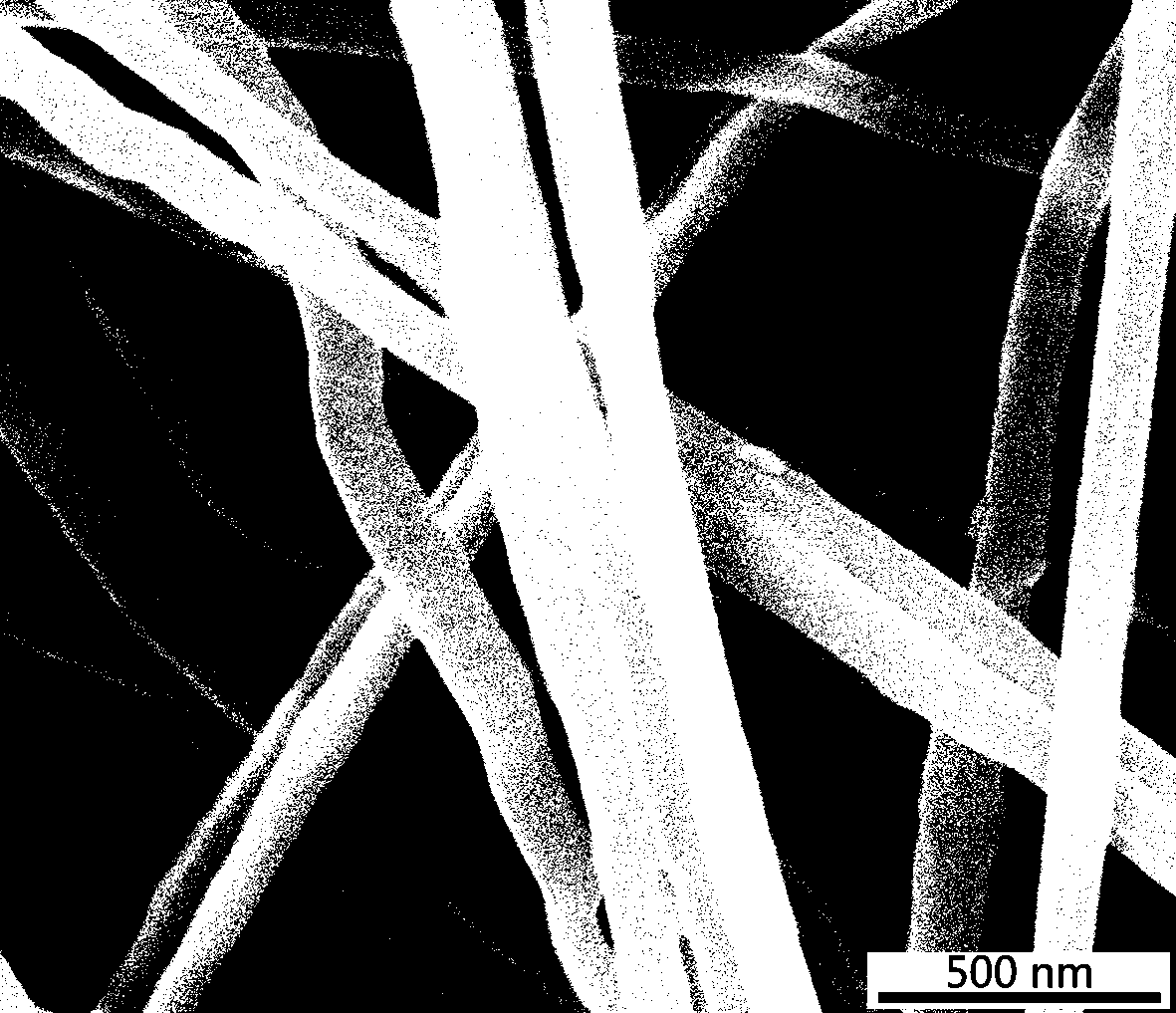

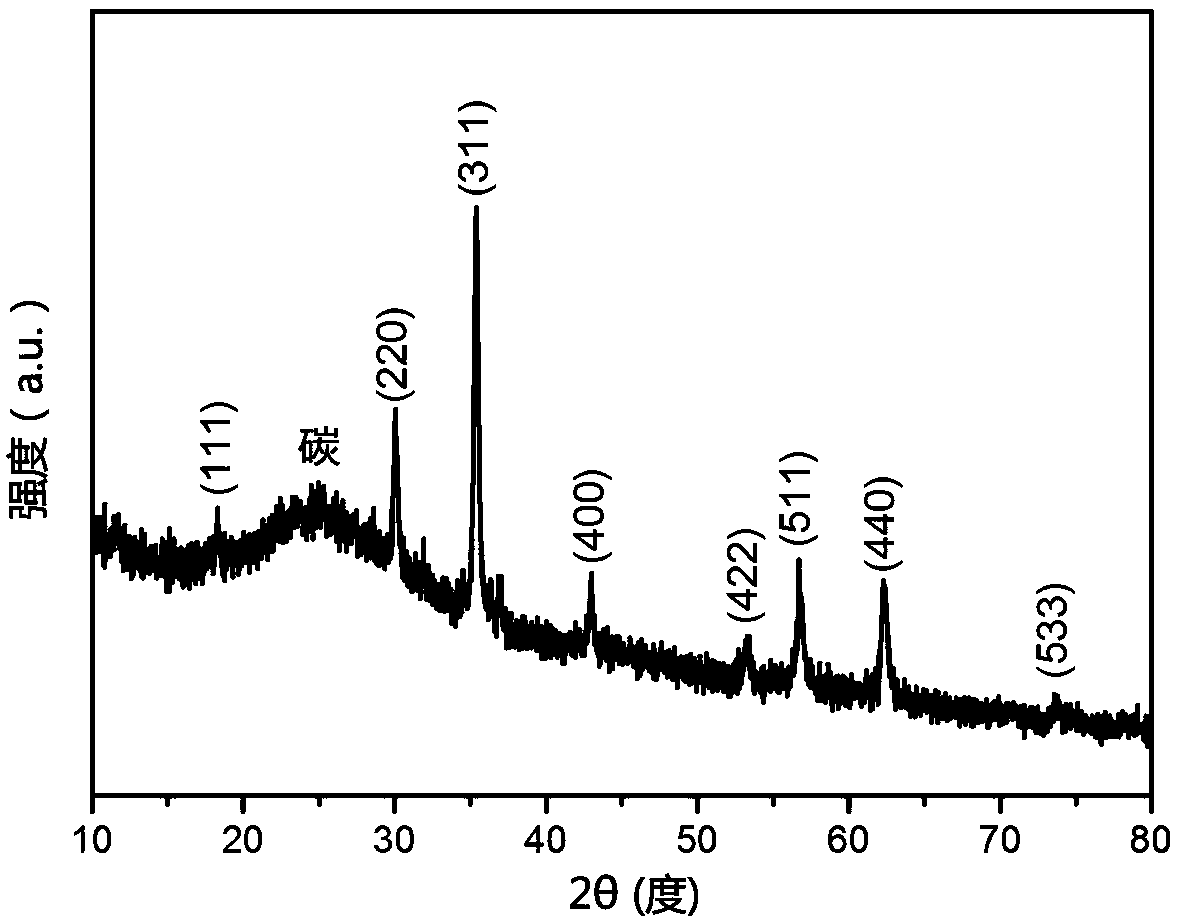

[0030] The prepared ZnFe 2 o 4 The SEM and TEM images of the nitrogen-doped carbon nanofib...

Embodiment 2

[0033]Add ferric chloride, zinc acetate, and polyacrylonitrile in a molar ratio of 2:1 to 10 mL of dimethylformamide solution in turn, the weight percentage of polyacrylonitrile in dimethylformamide is 5%, and the iron salt The concentration in dimethylformamide is 0.1 mol / L. The homogeneously mixed precursor solution was filled into a syringe with a metal needle with a diameter of 0.6 mm. Then, the electrospinning was carried out under the electrospinning conditions of a voltage of 20 kV, a bolus injection speed of 1.5 mL / min, and a distance of 20 cm between the needle and the receiver to obtain ZnFe 2 o 4 Precursors of nitrogen-doped carbon nanofibers. Finally, the obtained precursor was heated to 300 °C in air for 2 h, heated to 500 °C in argon, carbonized for 4 h, and heated to 350 °C in air for 2 h to obtain ZnFe 2 o 4 Nitrogen-doped carbon nanofiber composite electrode material.

Embodiment 3

[0035] Add ferric chloride, zinc acetate, and polyacrylonitrile at a molar ratio of 2:1 to 10 mL of dimethylformamide solution in turn, the weight percentage of polyacrylonitrile in dimethylformamide is 15%, and the iron salt The concentration in dimethylformamide is 0.07mol / L. The homogeneously mixed precursor solution was filled into a syringe with a metal needle with a diameter of 0.4 mm. Then, the electrospinning was carried out under the electrospinning conditions of a voltage of 15 kV, a bolus injection speed of 1 mL / min, and a distance of 15 cm between the needle and the receiver to obtain ZnFe 2 o 4 Precursors of nitrogen-doped carbon nanofibers. Finally, the obtained precursor was heated to 270 °C in air for 3 h, heated to 600 °C in argon, carbonized for 3 h, and heated to 300 °C in air for 3 h to obtain ZnFe 2 o 4 Nitrogen-doped carbon nanofiber composite electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com