Preparation method of silicon-based lithium ion battery negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of complex preparation process, uncontrollable, particle agglomeration, etc., and achieve simple operation, The effect of high safety and wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

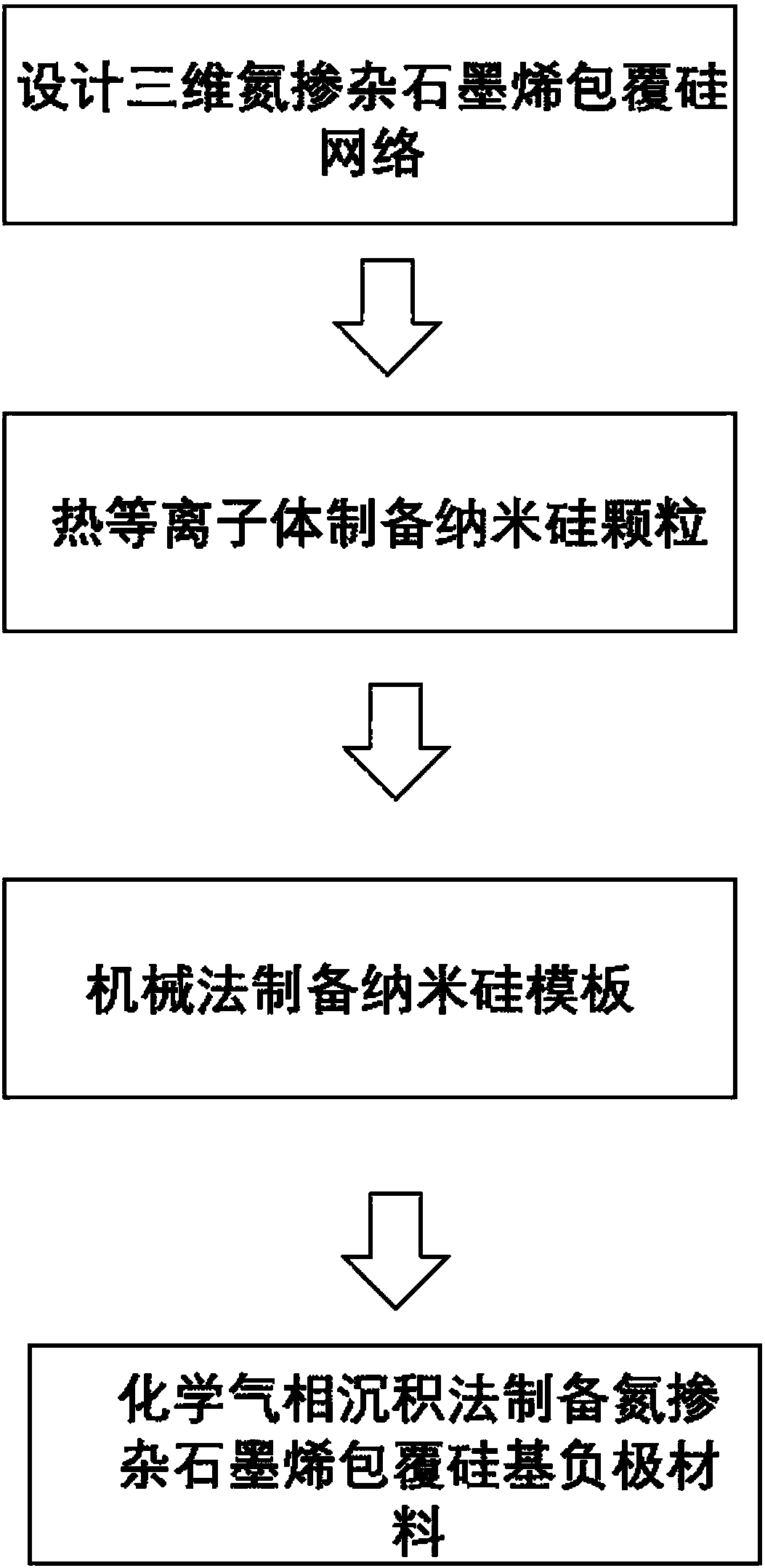

[0046] figure 1 A processing flow chart of a method for preparing a negative electrode material of a nitrogen-doped graphene-coated silicon-based lithium-ion battery by a chemical vapor deposition method provided in an embodiment of the present invention includes the following processing steps;

[0047] Step 1: Design a 3D nitrogen-doped graphene-coated silicon network.

[0048] figure 2 A schematic diagram of a nitrogen-doped graphene-coated silicon three-dimensional network designed for the present invention, and a diagram of the stress release process during lithiation.

[0049] Nitrogen doping can cause defects on graphene. In the three-dimensional nitrogen-doped graphene-coated silicon network, the redistribution of stress is induced by designing the site dispersion of defects; the stress redistribution refers to stress concentration in The location of the defect, so that the graphene layer is cut at the defect location, thereby releasing the huge stress during the sil...

Embodiment example 2

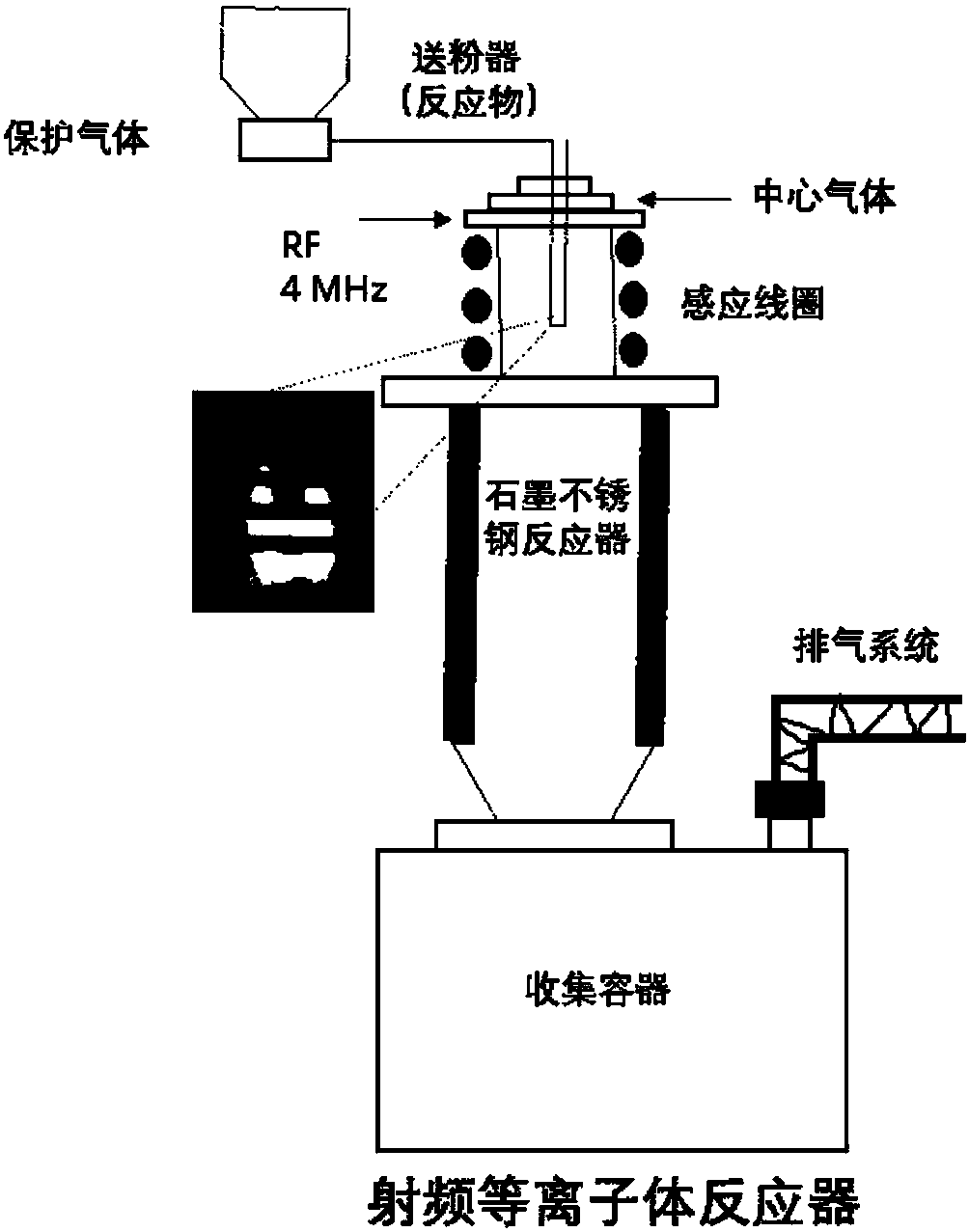

[0061] Implementation Case 2 Step 1: Prepare nano-silicon by thermal plasma method. The specific processing process includes:

[0062] image 3 It is a schematic structural diagram of a nano-silicon material preparation equipment provided in an embodiment of the present invention. Put the silicon-containing powder with a particle size of 20 microns as a raw material into the powder feeder;

[0063] Pass industrial grade gas (argon and methane mixed at 100:1) into the above plasma generator, in which the flow rate of argon as carrier gas is 0.3m3h-1, and the flow rate of argon as edge gas is 4.0m3h-1 , the flow rate of the central gas argon is 6m3h-1.

[0064] Turn on the powder feeder, the powder feeding speed of silicon powder is 4g / min, and other conditions are the same as case 1;

[0065] The finally prepared nanoparticles have a size of 103nm, smooth surface, compact structure and good dispersion. Other steps are the same as Case 1.

[0066] The particle size of the ...

Embodiment example 3

[0067] Implementation case 3 Steps 1 and 3 are the same as implementation case 1.

[0068] In step 2, 500 mg of the above-mentioned nano-silicon powder was weighed, and pressed on a tablet machine under a pressure of 20 kpa to obtain a silicon template.

[0069] Changing the pressure mentioned in this case can change the tap density of the nitrogen-doped graphene-coated silicon network.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com