A preparation method for dynamic coating of lithium-rich ternary lithium-ion battery positive electrode material by double-atmosphere roasting

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve problems that affect product rolling density and processing performance, low metal content in carbonate precursors, and low initial Coulombic efficiency of materials, etc. , to achieve the effect of improving cycle performance and coulombic efficiency, improving tap density and processing performance, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

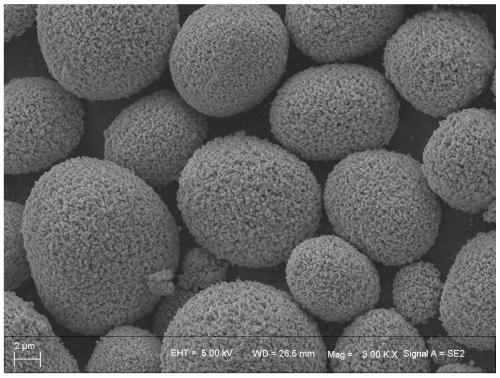

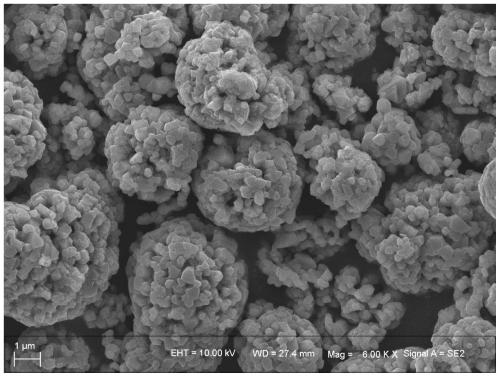

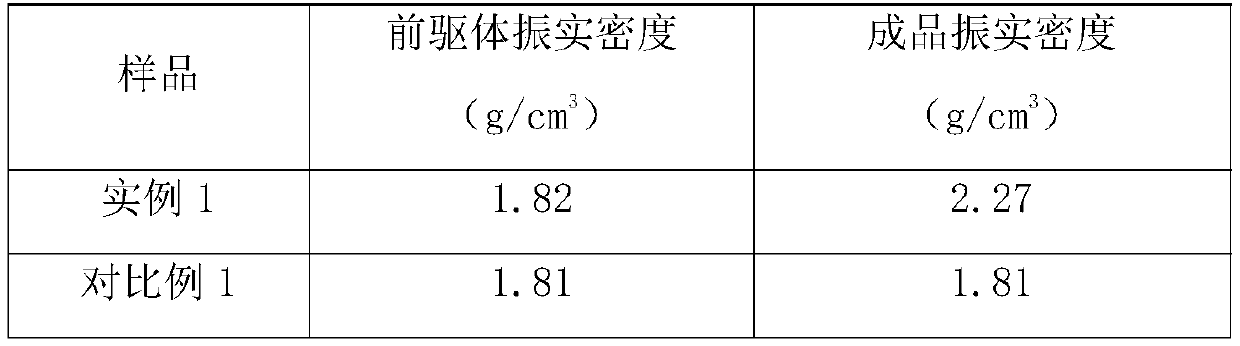

Image

Examples

Embodiment 1

[0030] A method for preparing a positive electrode material of a lithium-rich ternary lithium-ion battery dynamically coated with double-atmosphere roasting, comprising the following steps:

[0031] 1) According to the molar ratio Mn:Ni:Co=0.52:0.26:0.07, take manganese chloride, nickel chloride and cobalt chloride, and prepare a mixed salt solution with a total metal ion concentration of 1mol / L;

[0032] 2) Add ammoniacal liquor to 1mol / L sodium carbonate solution, the concentration of ammoniacal liquor in the solution is 0.25mol / L, marked as mixed alkali solution;

[0033] 3) Step temperature control reaction: under the condition of a stirring speed of 500 rpm, and control the temperature at 10°C; drop a mixed salt solution and a mixed alkali solution into the container, and control the pH of the solution to 7.8; react for 1 hour and raise the reaction temperature to 50 ℃;

[0034] 4) Aging for 6 hours, suction filtration, washing and drying to obtain the nickel-cobalt-mang...

Embodiment 2

[0044] A method for preparing a positive electrode material of a lithium-rich ternary lithium-ion battery dynamically coated with double-atmosphere roasting, comprising the following steps:

[0045] 1) According to the molar ratio Mn:Ni:Co=0.52:0.26:0.07, manganese nitrate, nickel nitrate and cobalt nitrate were weighed to prepare a mixed salt solution with a total metal ion concentration of 2mol / L;

[0046] 2) Add ammoniacal liquor in 2mol / L sodium carbonate solution, the concentration of ammoniacal liquor in the solution is 0.5mol / L, mark as mixed alkali solution;

[0047]3) Step temperature control reaction: under the condition of a stirring speed of 800 rpm, and control the temperature at 20°C;

[0048] Add the mixed salt solution and the mixed alkali solution dropwise into the container to control the pH of the solution to 8.2; react for 3 hours, and raise the reaction temperature to 60°C;

[0049] 4) Aging for 12 hours, suction filtration, washing and drying to obtain t...

Embodiment 3

[0059] A method for preparing a positive electrode material of a lithium-rich ternary lithium-ion battery dynamically coated with double-atmosphere roasting, comprising the following steps:

[0060] 1) According to the molar ratio Mn:Ni:Co=0.52:0.26:0.07, take manganese sulfate, nickel sulfate and cobalt sulfate, and prepare a mixed salt solution whose total concentration of metal ions is 2mol / L;

[0061] 2) Add ammonia water in 2mol / L sodium carbonate solution, the concentration of ammonia water in the solution is 0.25mol / L, marked as mixed alkali solution;

[0062] 3) Step temperature control reaction: under the condition of a stirring speed of 800 rpm, and control the temperature at 10°C;

[0063] Add the mixed salt solution and the mixed alkali solution dropwise to the container to control the pH of the solution to 8.0; react for 1 hour, and raise the reaction temperature to 55°C;

[0064] 4) Aging for 10 hours, suction filtration, washing and drying to obtain the nickel-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com