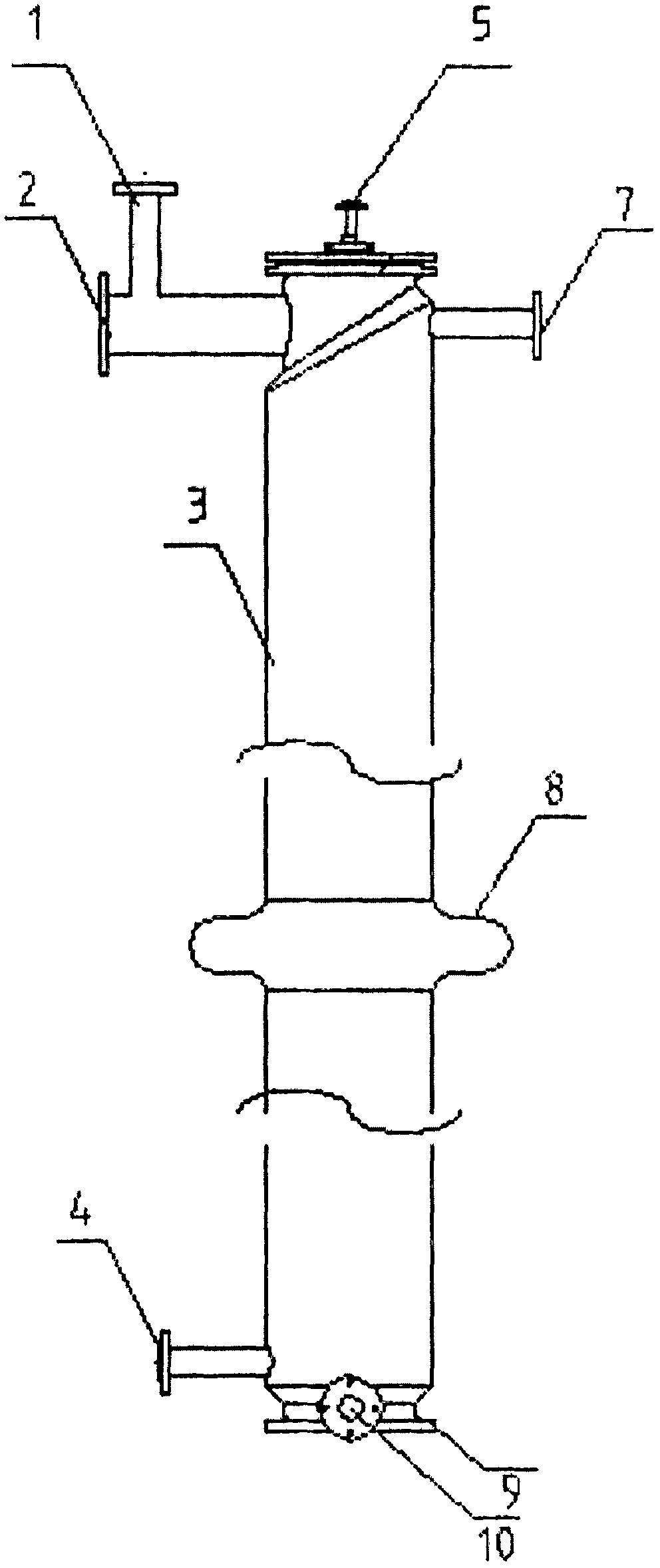

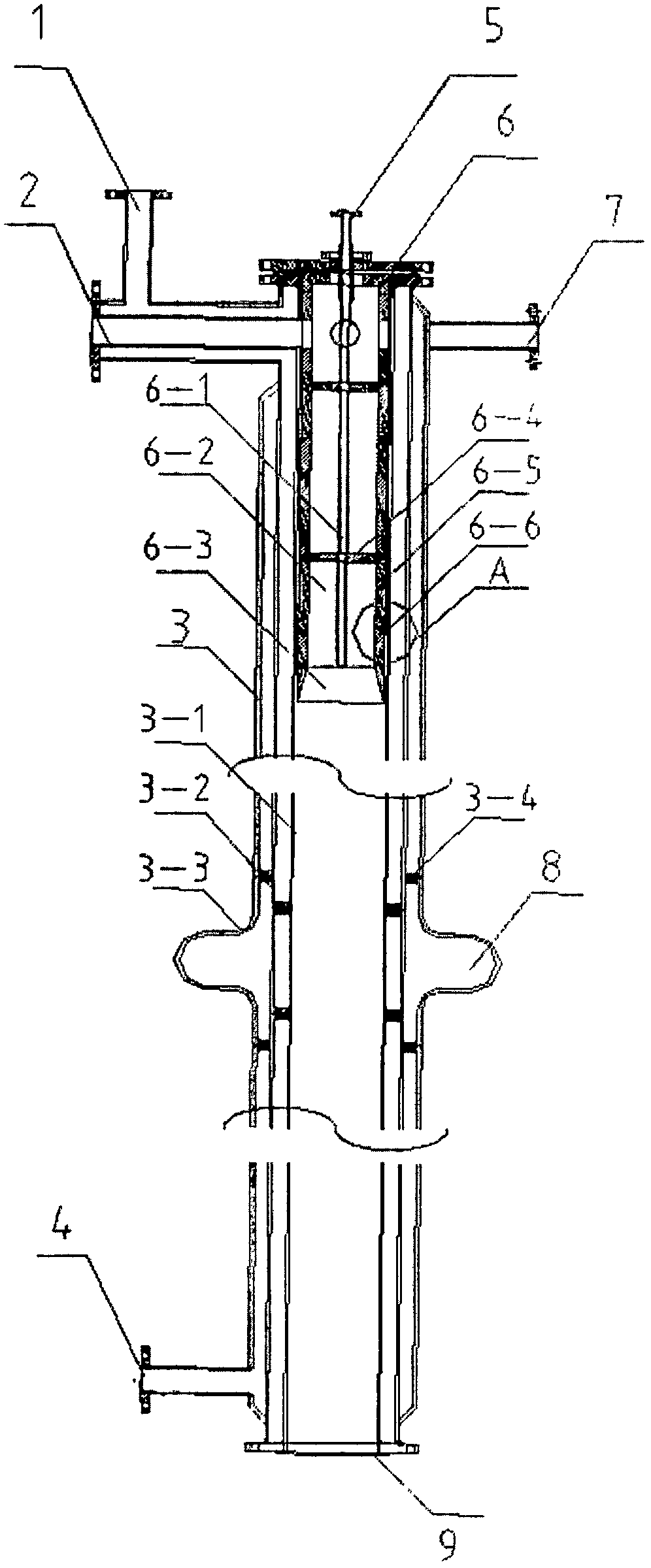

Gas-phase phosgenation reactor and application thereof in synthesis of organic isocyanates

A reactor and phosgenation technology, applied in the field of reactors, can solve the problems of difficult wall thickness detection, inflexible equipment adjustment, equipment fatigue, etc., to improve the flow field shape and reaction conditions, reduce average energy consumption and maintenance Cost, Guarantee Stability and Smooth Outcomes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

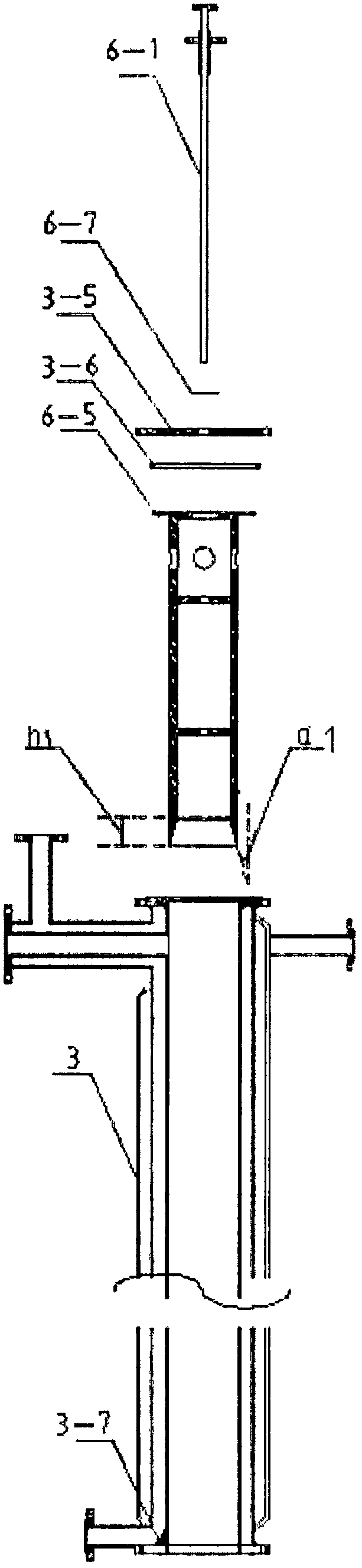

[0047] The length of the mixer bushing is 1100mm, the angle between the inclined surface of the expansion port and the vertical surface is 11.2°, the wall thickness of the mixer bushing is 31.5mm; the thickness of the ring gap between the outer wall of the mixer bushing and the inner wall of the reactor body is 8mm; organic amine and inert The diameter of the gas mixture channel pipe is φ26.7, and the distance between the outlet and the upper edge of the expansion port of the bushing is 45mm.

[0048] After preheating the reactor with 0.8MPa medium-pressure steam, start the molten salt circulation, and control the temperature of the heat-conducting molten salt to 342°C, and circulate the phosgene that is also preheated to 342°C into the reactor, and the flow rate of phosgene is 1650kg / h , adjust the internal pressure of the reactor to an absolute pressure of 78kPa, and after the pressure and phosgene flow are stable, put into the mixed gas of toluene diamine (TDA) and nitrogen ...

Embodiment 2

[0050] The length of the mixer bushing is 1100mm, the angle between the inclined surface of the expansion port and the vertical surface is 11.2°, and the wall thickness is 31.5mm; the thickness of the ring gap between the outer wall of the mixer bushing and the inner wall of the reactor body is 8mm; the mixed gas of organic amine and inert gas The diameter of the channel pipe is φ26.7, and the distance between the outlet and the upper edge of the expansion port of the bushing is 45mm.

[0051] After preheating the reactor with 0.8MPa medium-pressure steam, start the molten salt circulation, and control the temperature of the heat-conducting molten salt to 340°C, and circulate the phosgene that is also preheated to 340°C into the reactor, and the flow rate of phosgene is 1820kg / h , adjust the pressure in the reactor to be an absolute pressure of 83-85kPa, and after the pressure and phosgene flow are stable, drop into 4,4'-diaminodicyclohexylmethane (H 12 Mixed gas of MDA) and n...

Embodiment 3

[0053] The length of the mixer bushing is 920mm, the angle between the inclined surface of the expansion port and the vertical surface is 10.8°, and the wall thickness is 29mm; the thickness of the ring gap between the outer wall of the mixer bushing and the inner wall of the reactor body is 6mm; the mixed gas channel of organic amine and inert gas The diameter of the pipe is φ33.4, and the distance between the outlet and the upper edge of the expansion port of the bushing is 0mm.

[0054] After preheating the reactor with 0.8MPa medium-pressure steam, start the molten salt cycle, and control the temperature of the heat-conducting molten salt at 330-335°C, and circulate the phosgene that is also preheated to 330-335°C into the reactor. 1820kg / h, adjust the pressure inside the reactor to an absolute pressure of 85-90kPa, after the pressure and phosgene flow are stable, put in the mixed gas of isophoronediamine (IPDA) and nitrogen preheated to 330-335°C, of which IPDA The flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com