Preparation method of carbon nitride/zinc titanate/titanium oxide sandwich-like direct Z-shaped heterojunction composite photocatalyst

A zinc titanate and sandwich technology, applied in the field of organic dye pollutants, to achieve the effects of low cost, enhanced absorption range and strength, and improved redox ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

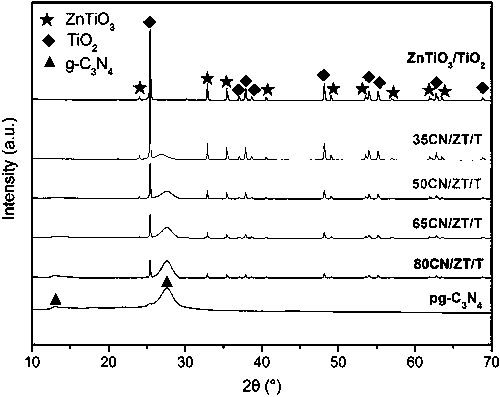

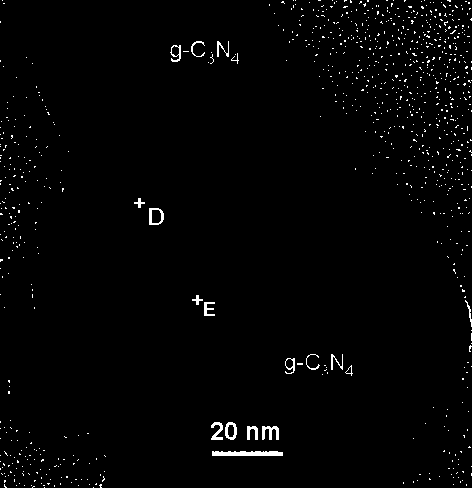

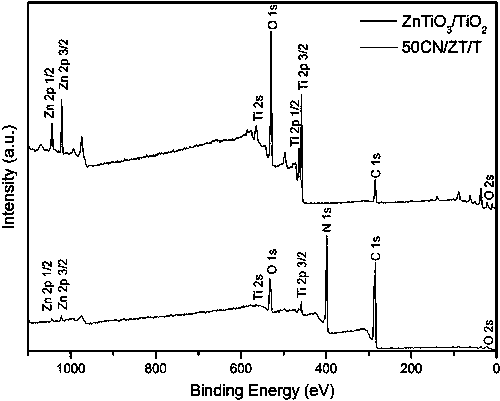

[0023] A method for preparing a carbon nitride / zinc titanate / titanium oxide sandwich direct Z-type heterojunction composite photocatalyst. Firstly, 20 g of urea was dissolved in 30 mL of distilled water to make urea aqueous solution, then the urea aqueous solution was placed in an alumina crucible with a cover, and then placed in a rapid heating electric furnace to raise the temperature to 400 °C at 15 °C / min and keep it for 1 h. Then the temperature was raised to 500 °C at 15 °C / min and kept for 2 h, after natural cooling, it was ground and sieved to obtain pg-C 3 N 4 sample. Add a solution containing 1.5 mol of zinc nitrate to an absolute ethanol solution containing 1 mol of titanium tetrachloride, add ammonia water to adjust the pH to 9.6 while stirring, and then adjust the pH to 8.0 with hydrochloric acid to obtain ZnTiO 3 / TiO 2Precursor suspension, the suspension was placed in a stainless steel hydrothermal reaction kettle and kept at a filling degree of 80%, then tig...

Embodiment 2

[0025] A method for preparing a carbon nitride / zinc titanate / titanium oxide sandwich direct Z-type heterojunction composite photocatalyst. Firstly, 30 g of urea was dissolved in 30 mL of distilled water to make urea aqueous solution, then the urea aqueous solution was placed in an alumina crucible with a cover, and then placed in a rapid heating electric furnace to raise the temperature to 400 °C at 10 °C / min and keep it for 1 h. Then the temperature was raised to 550 °C at 10 °C / min and kept for 2 h, after natural cooling, it was ground and sieved to obtain pg-C 3 N 4 sample. Add a solution containing 2 mol of zinc nitrate to an absolute ethanol solution containing 1 mol of titanium tetrachloride, add ammonia water to adjust the pH to 9.4 while stirring, and then adjust the pH to 7.8 with hydrochloric acid to obtain ZnTiO 3 / TiO 2 Precursor suspension, the suspension was placed in a stainless steel hydrothermal reaction kettle and kept at a filling degree of 80%, then tigh...

Embodiment 3

[0027] A method for preparing a carbon nitride / zinc titanate / titanium oxide sandwich direct Z-type heterojunction composite photocatalyst. Firstly, 15 g of urea was dissolved in 30 mL of distilled water to make urea aqueous solution, then the urea aqueous solution was placed in an alumina crucible with a cover, and then placed in a rapid heating electric furnace to raise the temperature to 400 °C at 10 °C / min and keep it for 1 h. Then the temperature was raised to 450 °C at 10 °C / min and kept for 2 h, after natural cooling, it was ground and sieved to obtain pg-C 3 N 4 sample. Add a solution containing 2.5 mol of zinc nitrate to an absolute ethanol solution containing 1 mol of titanium tetrachloride, add ammonia water to adjust the pH to 9.2 while stirring, and then adjust the pH to 7.8 with hydrochloric acid to obtain ZnTiO 3 / TiO 2 Precursor suspension, the suspension was placed in a stainless steel hydrothermal reaction kettle and kept at a filling degree of 80%, then ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com