Molybdenum-tungsten oxide pre-finishing scavenging technology

A technology of molybdenum oxide and pre-concentration, which is applied in flotation, chemical instruments and methods, solid separation, etc., and can solve the problems of complex process and high enrichment ratio of concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

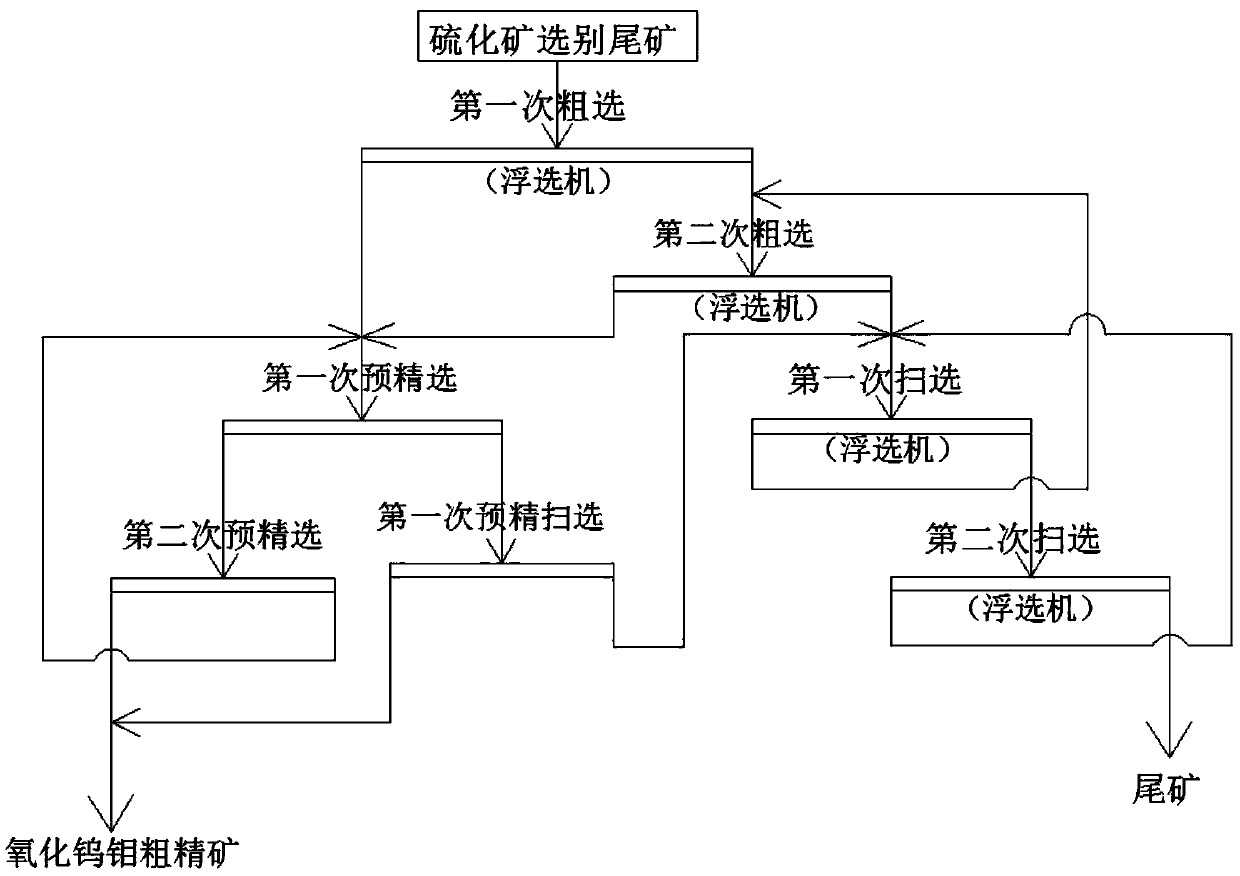

[0042] A kind of molybdenum tungsten oxide pre-finishing sweeping process, comprises the following steps:

[0043] (1) Take the raw molybdenum oxide and tungsten oxide ore to be processed for crushing (conventional crushing method to a particle size of 25-50 mm), ore grinding (commonly used methods for grinding to a mass percentage of particles with a particle size of less than 75 μm is 75-80%), Classification and desliming treatment, and then use common methods to separate sulfide ores, and obtain tailings after sorting sulfide ores;

[0044] The grading treatment is as follows: using a hydrocyclone and performing grading treatment by conventional methods, the sedimentation obtained after grading directly enters the subsequent sulfide ore sorting procedure, and the overflow product obtained after grading is firstly subjected to desliming treatment. The product after mud treatment is mixed with the above-mentioned settling sand and enters the sulfide ore sorting procedure;

...

Embodiment 2

[0061] A kind of molybdenum tungsten oxide pre-finishing sweeping process, comprises the following steps:

[0062] (1) Take the unprocessed molybdenum tungsten oxide raw ore (the grade of tungsten oxide is 0.105-0.115%, and the grade of molybdenum is 0.13-0.16%) for crushing, grinding, grading, and desliming treatment, and then use common methods to separate sulfide ores, After the sorting is completed, the tailings after sorting the sulfide ore are obtained. The molybdenum grade in the tailings is 0.065-0.075%, and the tungsten grade is 0.105-0.115%;

[0063] (2) The tailings that step (1) obtains adopts two flotation machines (GF-1.1) to carry out the rough selection for the first time, the rough selection for the second time successively;

[0064] Specifically: first add tailings, sodium carbonate (420-510) g / t, water glass (870-1000) g / t and EZ-5 (216-264) g into the buffer tank of the first flotation machine / t, mix and stir evenly, after stirring evenly, pass the buffe...

Embodiment 3

[0076] A kind of molybdenum tungsten oxide pre-finishing sweeping process, comprises the following steps:

[0077] (1) Take the unprocessed molybdenum tungsten oxide raw ore (the grade of tungsten oxide is 0.105-0.115%, and the grade of molybdenum is 0.13-0.16%) for crushing, grinding, grading, and desliming treatment, and then use common methods to separate sulfide ores, After the sorting is completed, the tailings after sorting the sulfide ore are obtained. The molybdenum grade in the tailings is 0.07%, and the tungsten grade is 0.11%;

[0078] (2) The tailings that step (1) obtains adopts two flotation machines (GF-1.1) to carry out the rough selection for the first time, the rough selection for the second time successively;

[0079] Specifically: first add tailings, sodium carbonate (420-510) g / t, water glass (870-1000) g / t and EZ-5 (216-264) g into the buffer tank of the first flotation machine / t, mix and stir evenly, after stirring evenly, pass the buffer tank into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com