Method for preparing yttrium oxide transparent ceramic through co-precipitation

A technology of transparent ceramics and yttrium oxide, which is applied in the production field of transparent ceramics, can solve problems such as unstable batches, poor repeatability, and unstable performance of transparent ceramics, and achieve high yield, simple operation, and controllable experimental results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

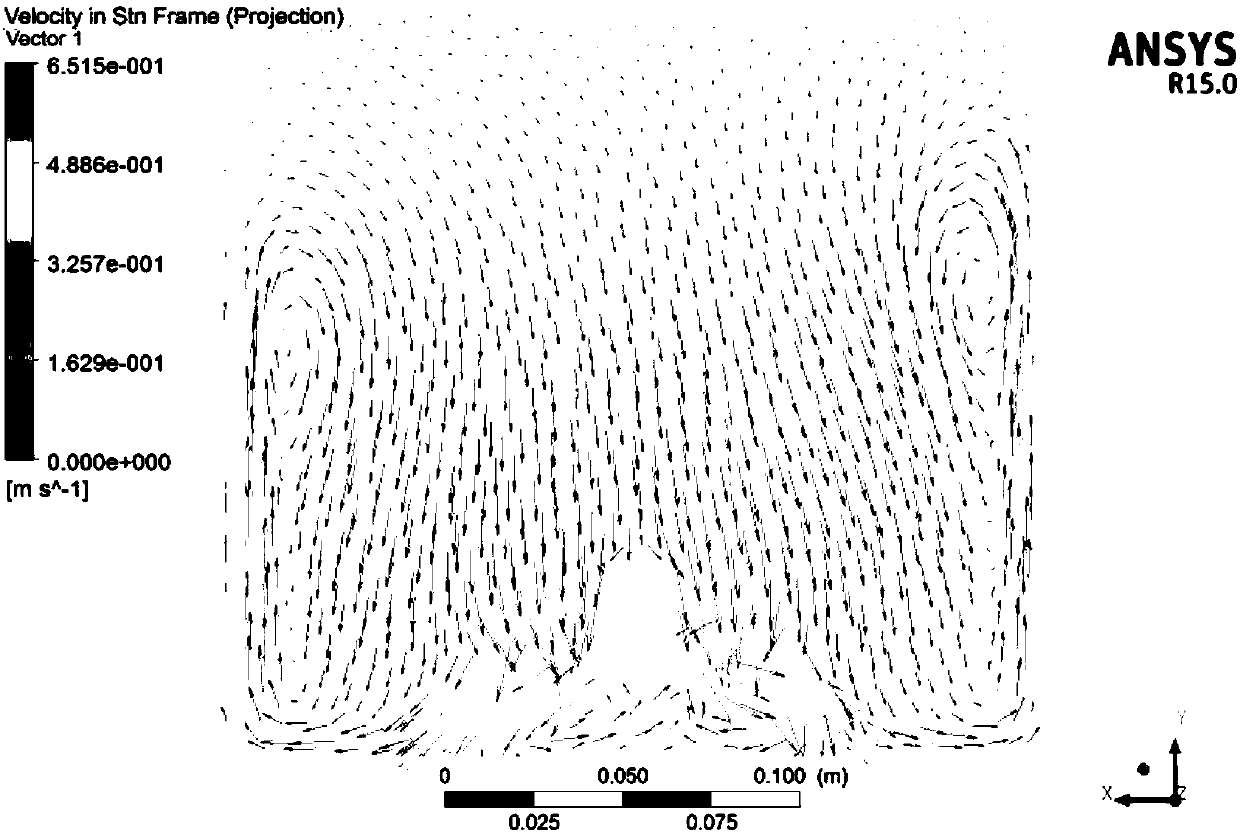

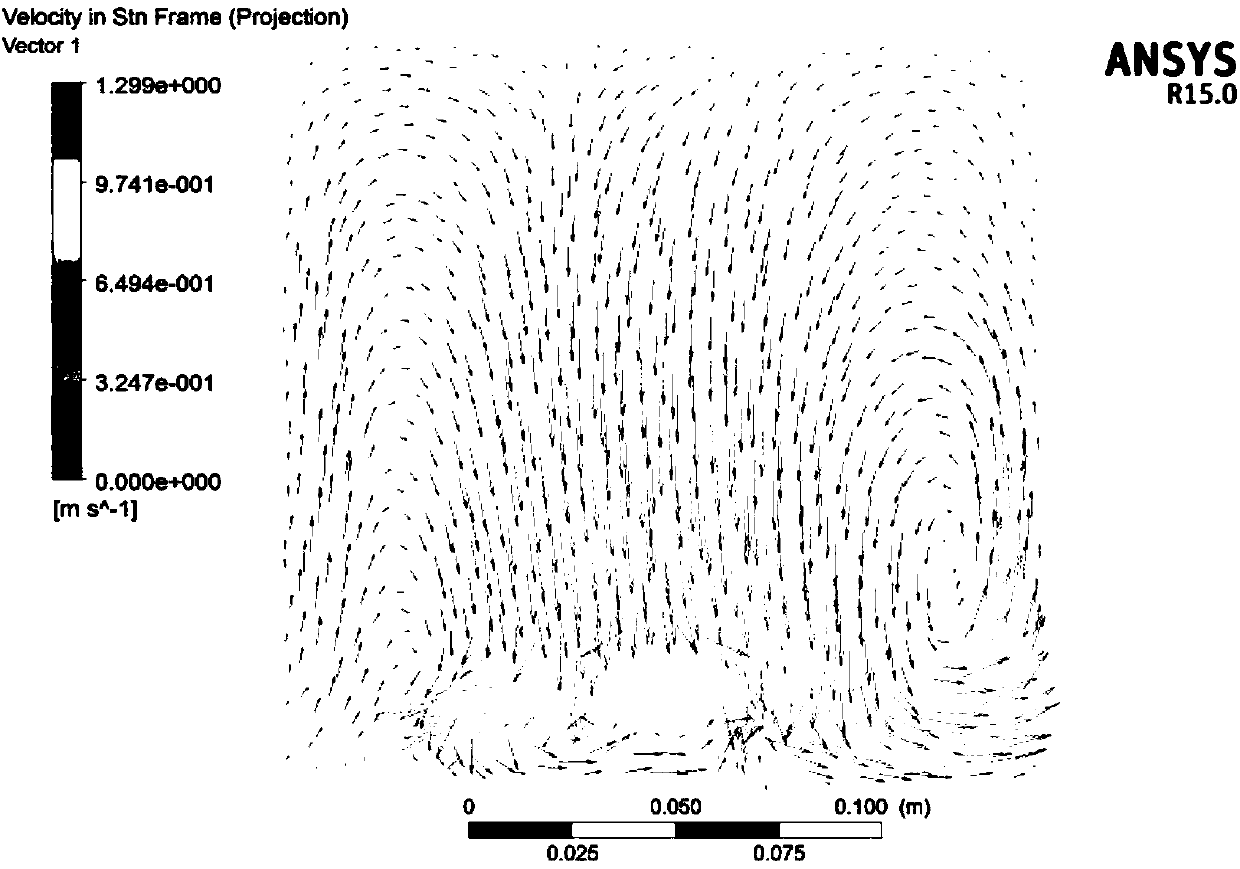

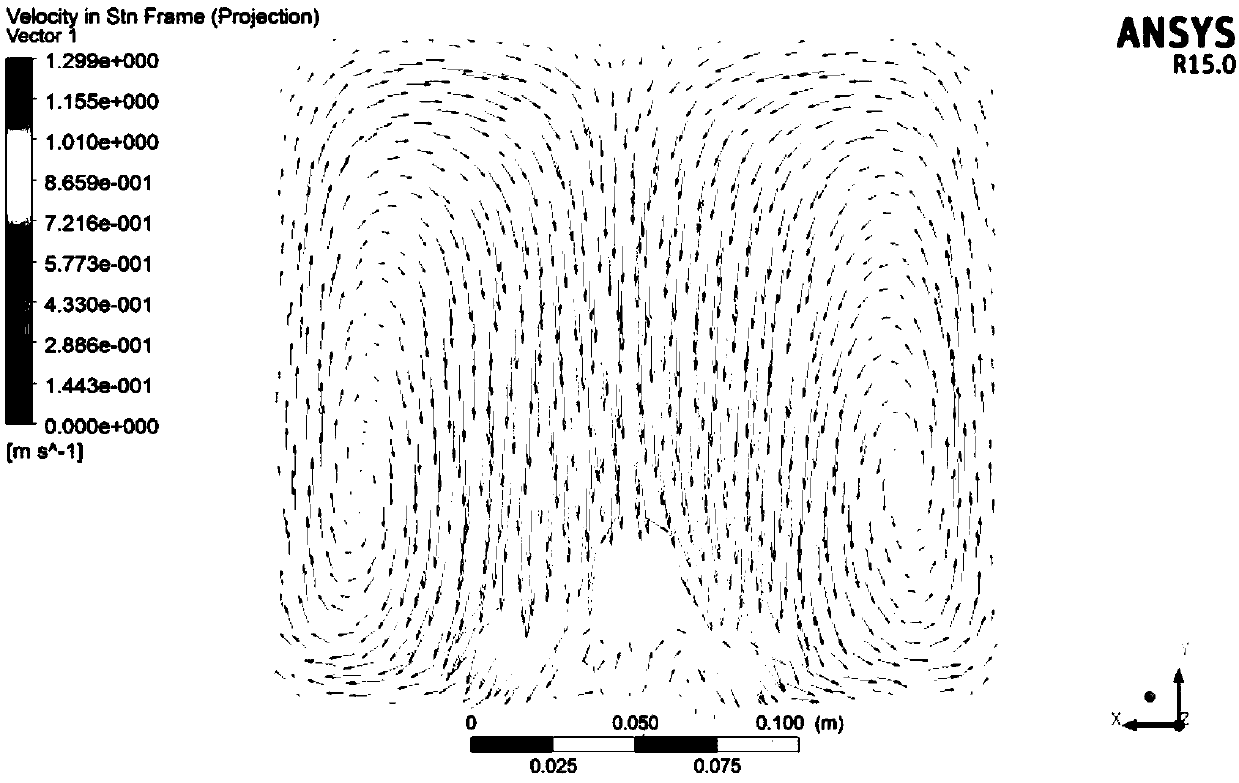

[0020] Firstly, the yttrium nitrate solution and the composite precipitant solution of ammonia water and ammonium bicarbonate are configured; then, the precipitant solution is pumped into the yttrium nitrate solution, and the agitator is stirred during the co-precipitation process. When the pH value at the end of the reaction is between 8 and 9, stop pumping and stirring; after the solution is allowed to stand for aging, deionization and ethanol are sequentially added for suction filtration, drying, and calcination to obtain nanometer Y 2 o 3 Powder. then Y 2 o 3 After dry pressing and cold isostatic pressing of the powder, bisque firing, vacuum sintering, annealing, and grinding and polishing are carried out to obtain Y 2 o 3 Transparent ceramics, the main content of which is that during the co-precipitation reaction, the stirring rate of the reaction solution is strictly and precisely controlled, and the specific steps are as follows:

[0021] 1) Co-precipitation reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com