A kind of preparation method of porous dicalcium silicate bioactive ceramic support

A technology of dicalcium silicate biological and active ceramics, applied in the field of materials science, can solve the problems of complex molding process, inability to precisely control the scaffold structure, etc., and achieve simple molding process, excellent biodegradation performance and mineralization performance, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

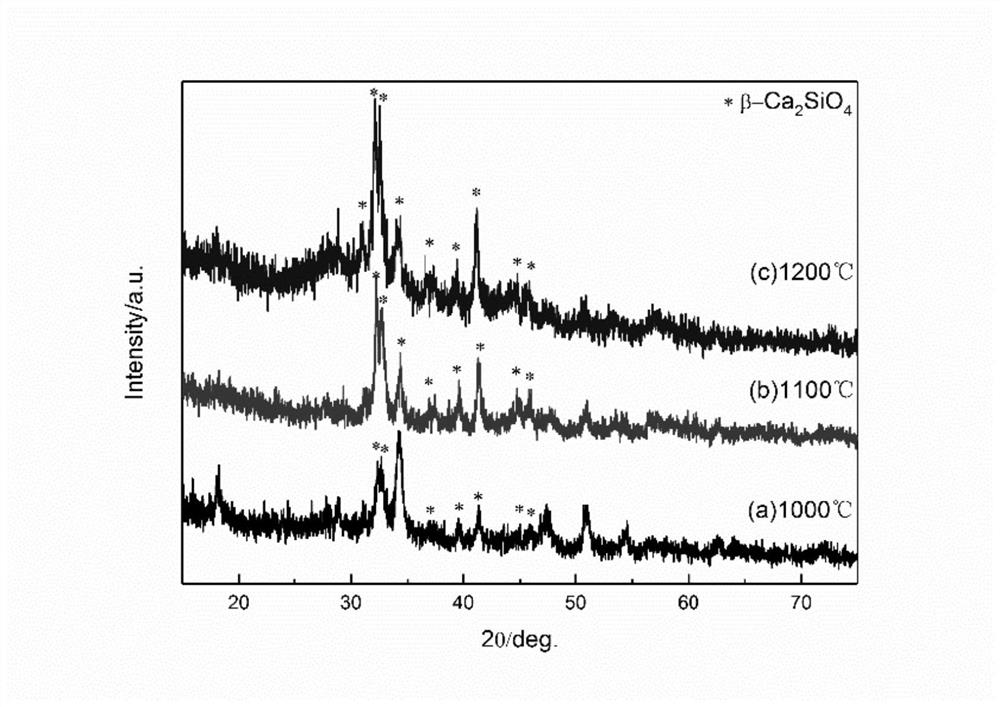

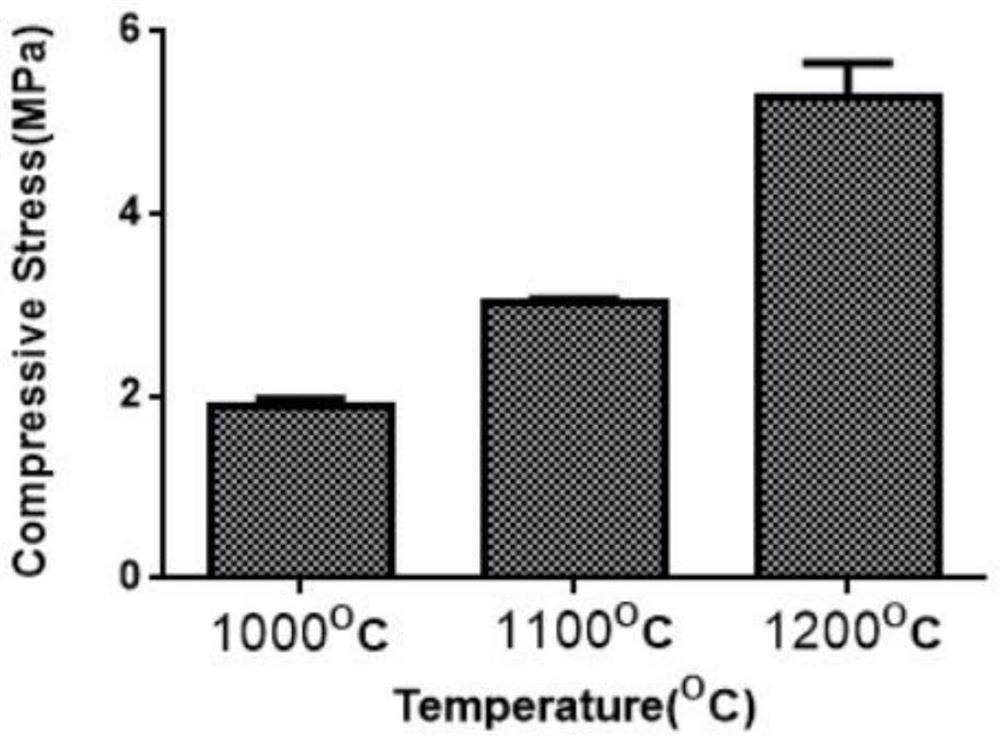

[0021] A kind of porous dicalcium silicate active ceramic support of the present invention and preparation method thereof, comprises the following steps:

[0022] Step one, prepare a silicone resin / isopropanol solution. Mix the silicone resin and isopropanol evenly according to the mass volume ratio of 1.25g / ml, stir quickly and evenly, and then seal and store.

[0023] Step 2, preparing silicone resin / calcium carbonate printing paste. Pass the calcium carbonate powder through a 400-mesh sieve, then take a certain amount of calcium carbonate according to the mass ratio of calcium carbonate and silicone resin of 2.79:1, add the silicone resin / isopropanol solution prepared in step 1, stir quickly and evenly, Then keep it sealed.

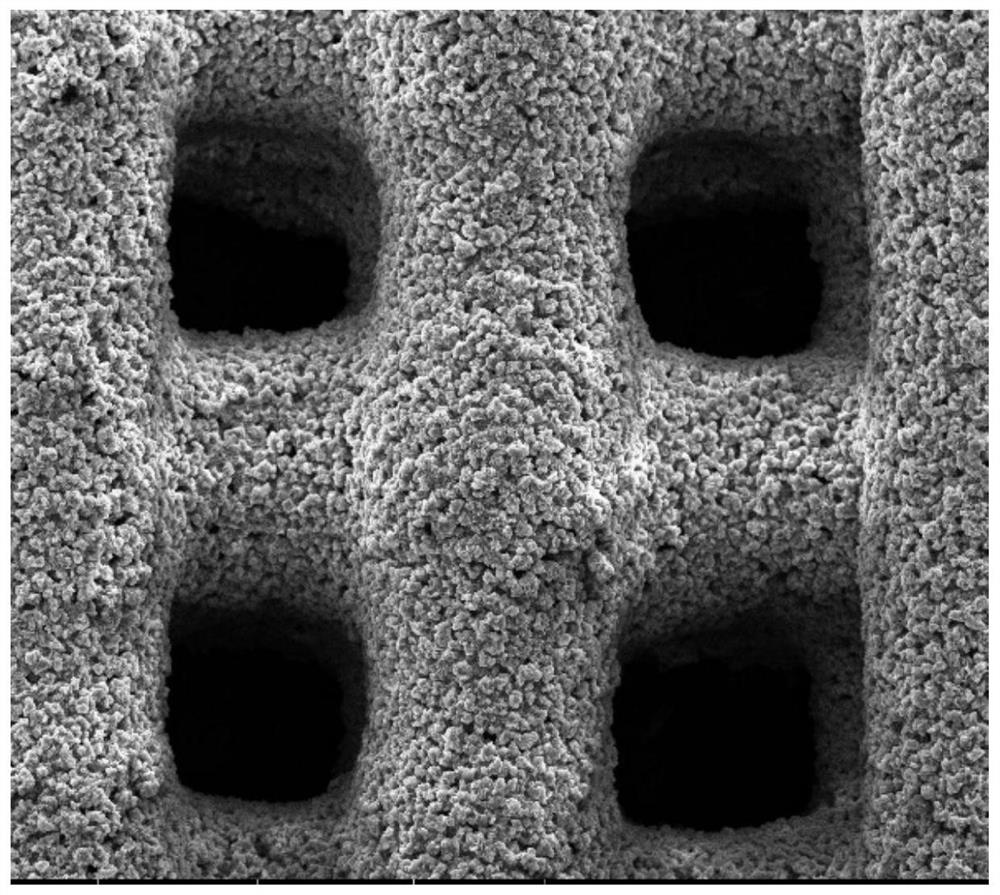

[0024] Step three, designing the external shape and internal structure of the silicone resin / calcium carbonate stent. CAD computer-aided software was used to design the external shape and internal structure of the scaffold. The scaffold model was bl...

Embodiment 2

[0028] A kind of preparation method of porous dicalcium silicate active ceramic support of the present invention, comprises the following steps:

[0029] Step one, prepare a silicone resin / isopropanol solution. Mix the silicone resin and isopropanol evenly according to the mass volume ratio of 1.43g / ml, stir quickly and evenly, and then seal and store.

[0030] Step 2, preparing silicone resin / calcium carbonate printing paste. Pass the calcium carbonate powder through a 400-mesh sieve, then take a certain amount of calcium carbonate according to the mass ratio of calcium carbonate and silicone resin of 2.79:1, add the silicone resin / isopropanol solution prepared in step 1, stir quickly and evenly, Then keep it sealed.

[0031] Step three, designing the external shape and internal structure of the silicone resin / calcium carbonate stent. Using CAD computer-aided software to design the external shape and internal structure of the scaffold, the scaffold model is block (8×8×8mm)...

Embodiment 3

[0035] A kind of preparation method of porous dicalcium silicate active ceramic support of the present invention, comprises the following steps:

[0036] Step one, prepare a silicone resin / isopropanol solution. Mix the silicone resin and isopropanol evenly according to the mass volume ratio of 1.67g / ml, stir quickly and evenly, and then seal and store.

[0037] Step 2, preparing silicone resin / calcium carbonate printing paste. Pass the calcium carbonate powder through a 200-mesh sieve, then take a certain amount of calcium carbonate according to the mass ratio of calcium carbonate and silicone resin of 2.79:1, add the silicone resin / isopropanol solution prepared in step 1, stir quickly and evenly, Then keep it sealed.

[0038]Step three, designing the external shape and internal structure of the silicone resin / calcium carbonate stent. Using CAD computer-aided software to design the external shape and internal structure of the scaffold, the scaffold model is block (8×8×8mm),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com