Barium titanate piezoelectric ceramic support for bone tissue engineering and preparation method thereof

A technology of bone tissue engineering and piezoelectric ceramics, applied in the field of materials science, can solve problems such as the inability to precisely control the internal structure and pore connectivity of the scaffold, and achieve improved biological performance, good biological activity and piezoelectricity, and molding process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

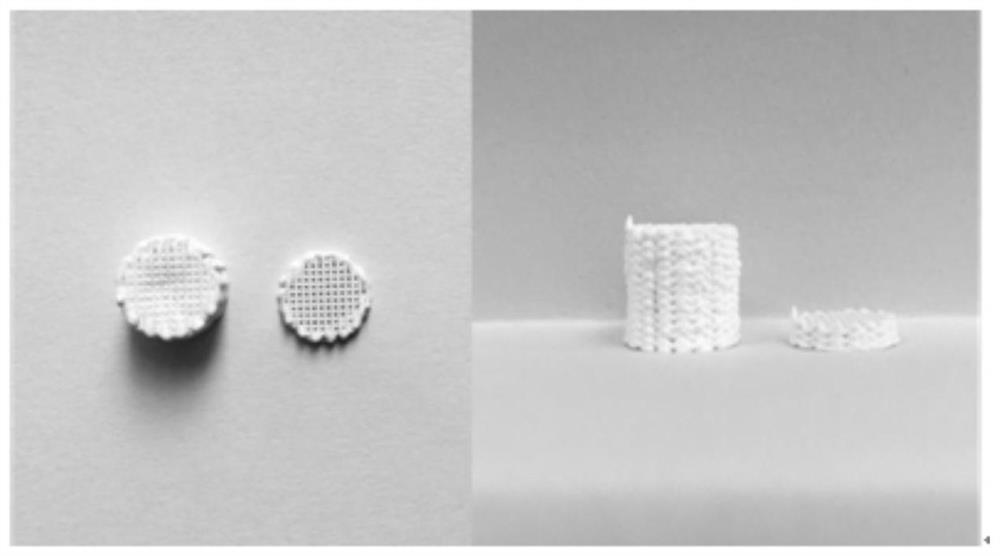

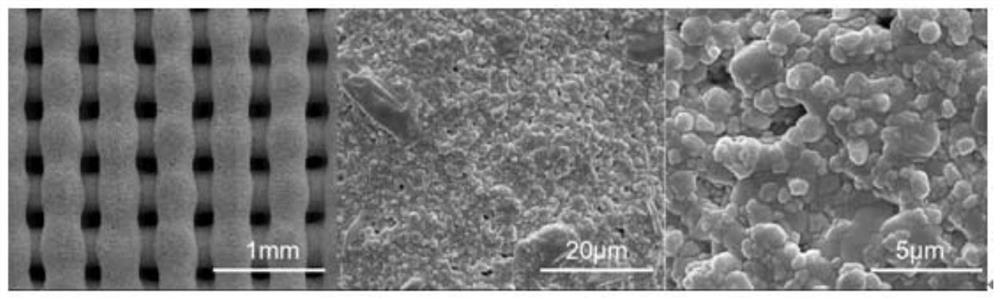

[0030] A barium titanate piezoelectric ceramic support for bone tissue engineering, the specific steps are:

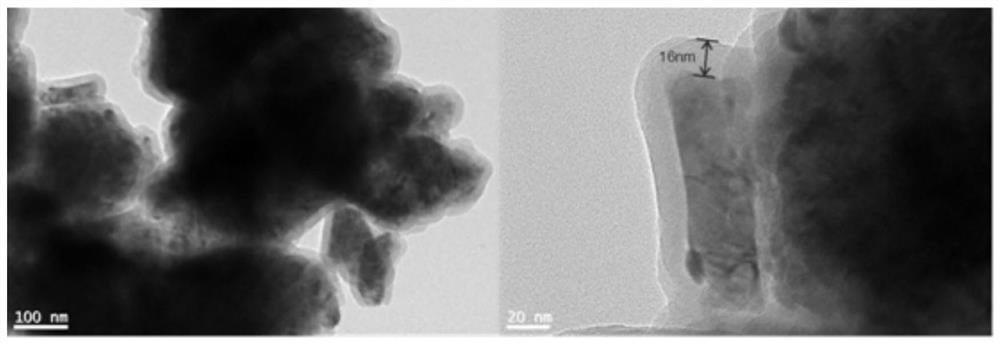

[0031] Step 1: Disperse 20g of barium titanate nanoparticles with a particle size of ≤1 micron in 100mL of ethanol, add 5mL of acetic acid with a molar concentration of 17.5mol / L to activate, stir for 30min, and after ultrasonic treatment for 30min, add 8g of Tetraethyl silicate, add ammonia water with a molar concentration of 14.8mol / L to adjust the pH value to 9, stir, then add 2g of calcium nitrate tetrahydrate, stir at 40°C for 4h, collect the solid by centrifugation and wash until neutral, bake at 60°C dry to obtain barium titanate powder coated with bioactive glass (BTO@BG), the bioactive glass is evenly coated on the surface of barium titanate, and the mass ratio of barium titanate and bioactive glass is 100:15.

[0032] Step 2: Mix 70wt% of barium titanate powder coated with bioactive glass, 20wt% ethanol, and 10wt% of binder polyvinylpyrrolidone (K60), stir qu...

Embodiment 2

[0037] A barium titanate piezoelectric ceramic support for bone tissue engineering, the specific steps are:

[0038] Step 1: Disperse 20g of barium titanate nanoparticles with a particle size of ≤1 micron in 100mL of ethanol, add 5mL of acetic acid with a molar concentration of 17.5mol / L to activate, stir for 30min, and after ultrasonic treatment for 30min, add 5g of normal Tetraethyl silicate, add ammonia water with a molar concentration of 14.8mol / L to adjust the pH value to 9.5, stir, then add 1.5g calcium nitrate tetrahydrate, stir at 40°C for 4h, collect the solid by centrifugation and wash until neutral, bake at 60°C dry to obtain barium titanate powder coated with bioactive glass (BTO@BG), the bioactive glass is uniformly coated on the surface of barium titanate, and the mass ratio of barium titanate and bioactive glass is 100:10.

[0039]Step 2: Mix 75wt% of barium titanate powder coated with bioactive glass, 10wt% ethanol, and 15wt% of binder polyvinylpyrrolidone (K60...

Embodiment 3

[0044] A barium titanate piezoelectric ceramic support for bone tissue engineering, the specific steps are:

[0045] Step 1: Disperse 20g of barium titanate nanoparticles with a particle size of ≤1 micron in 100mL of ethanol, add 5mL of acetic acid with a molar concentration of 17.5mol / L to activate, stir for 30min, and after ultrasonic treatment for 30min, add 3g of normal Tetraethyl silicate, add ammonia water with a molar concentration of 14.8mol / L to adjust the pH value to 8.5, stir, then add 0.8g calcium nitrate tetrahydrate, stir at 40°C for 4h, collect the solid by centrifugation and wash until neutral, bake at 60°C dry to obtain barium titanate powder coated with bioactive glass (BTO@BG), the bioactive glass is uniformly coated on the surface of barium titanate, and the mass ratio of barium titanate and bioactive glass is 100:20.

[0046] Step 2: Mix 60wt% of barium titanate powder coated with bioactive glass, 15wt% ethanol, and 25wt% of binder polyvinylpyrrolidone (K3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com