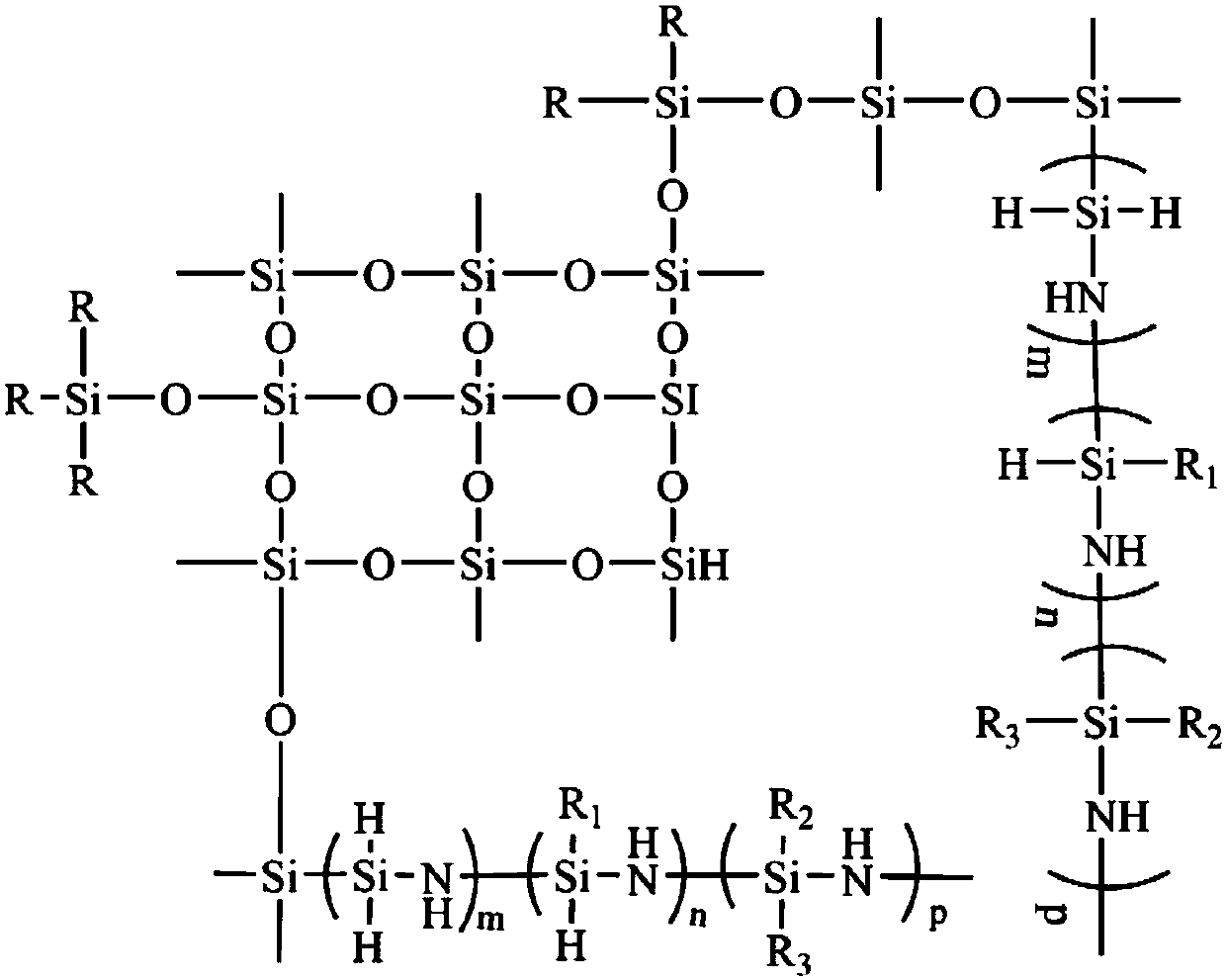

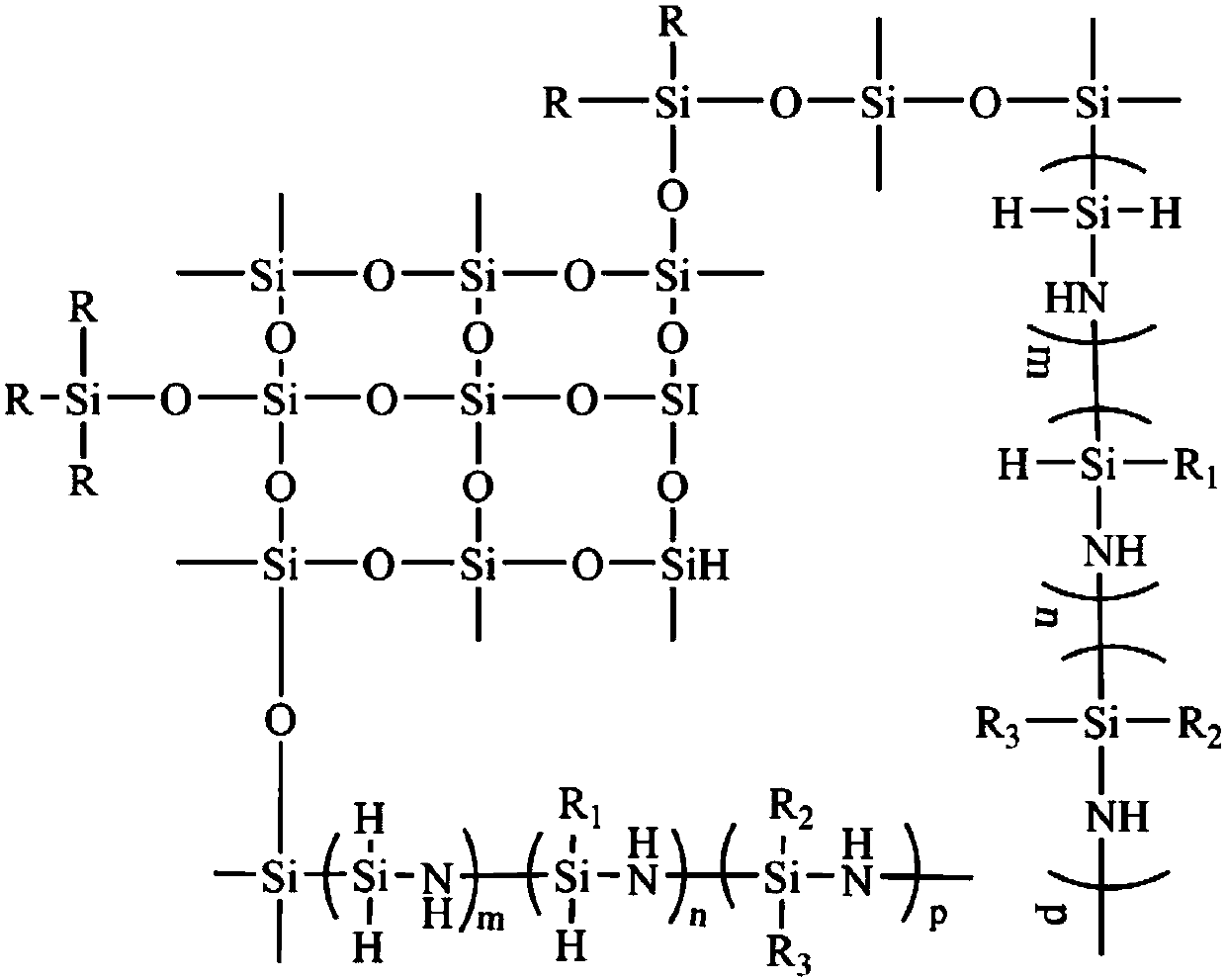

Ultrahard organosilicone hydrophobic glass resin and preparation method thereof

A technology of hydrophobic glass and silicone, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of expensive polysilazane and achieve high density, high hydrophobicity, Uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, 50 parts of liquid hydrogen-containing polymethylhydrogen siloxane (active hydrogen content 1.0%), 10 parts of vinyl MQ silicone resin (vinyl content 2.2%), 5-10 parts of polyhydroxy polysiloxane (viscosity 30mm 2 / s), 2 parts of amino-terminated silicone oil (viscosity 100mm 2 / s), 300 parts of xylene were added to the reactor, stirred evenly, then added 0.5 parts of chloroplatinic acid solution with a platinum concentration of 1500 ppm, 0.6 parts of KH560, heated to 80 ° C for 5 hours, cooled to room temperature and added 10 parts of complete Hydrogen polysilazane was stirred and reacted for 5 hours to obtain the superhard silicone hydrophobic glass resin.

Embodiment 2

[0024] First, 50 parts of liquid hydrogen-containing polymethylhydrogen siloxane (active hydrogen content 1.5%), 10 parts of vinyl MQ silicone resin (vinyl content 1.5%), 8 parts of polyhydroxypolysiloxane (viscosity 100mm 2 / s), 5 parts of amino silicone oil (viscosity 100mm 2 / s), 200 parts of petroleum ether (distillation range 90-120°C) were added to the reactor, stirred evenly, then 1.5 parts of platinum complex solution with a platinum concentration of 1500ppm, 0.9 parts of KH550 were added, heated to 60°C for 3 hours, After cooling to room temperature, 6 parts of perhydropolysilazane were added, and the reaction was continued to stir for 4 hours to obtain the superhard silicone hydrophobic glass resin.

Embodiment 3

[0026] First, 50 parts of liquid hydrogen-containing polymethylhydrogen siloxane (active hydrogen content 0.8%), 7 parts of vinyl MQ silicone resin (vinyl content 2.5%), 8 parts of polyhydroxypolysiloxane (viscosity 100mm2 / s), 4 parts of amino silicone oil (viscosity 200mm2 / s), 250 parts of solvent (xylene / cyclohexane=6 / 4) are added to the reactor, stirred evenly, and then 1.5 parts of platinum complexes with a platinum concentration of 1500ppm are added Solution, 1 part of methyltriethoxysilane coupling agent, heated to 90 ° C for 3 hours, cooled to room temperature, added 10 parts of perhydropolysilazane, and continued to stir for 3 hours to obtain the superhard silicone hydrophobic glass resin.

[0027] The organosilicon hydrophobic glass resin in the present embodiment is spray-coated on the glass surface (coating amount is 10g / m 2 ), test the coating performance after standing at room temperature for 24h.

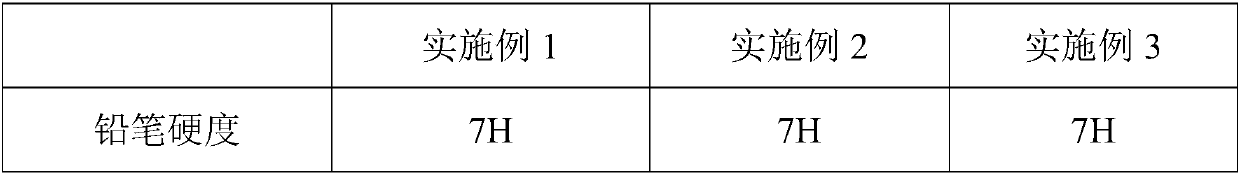

[0028] Coating film performance technical index in the embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com