Gas turbine intake air treatment system integrating pollutant cleaning, filtration and evaporative cooling

A technology of evaporative cooling and gas turbine, which is applied in the direction of combustion air/combustion-air treatment, gas turbine device, turbine/propulsion device inlet, etc. It can solve the problem of no evaporative cooling cleaning device, reduction of steam turbine output, low energy utilization rate, etc. problems, achieve the effect of reducing gas pollutants, improving output and efficiency, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

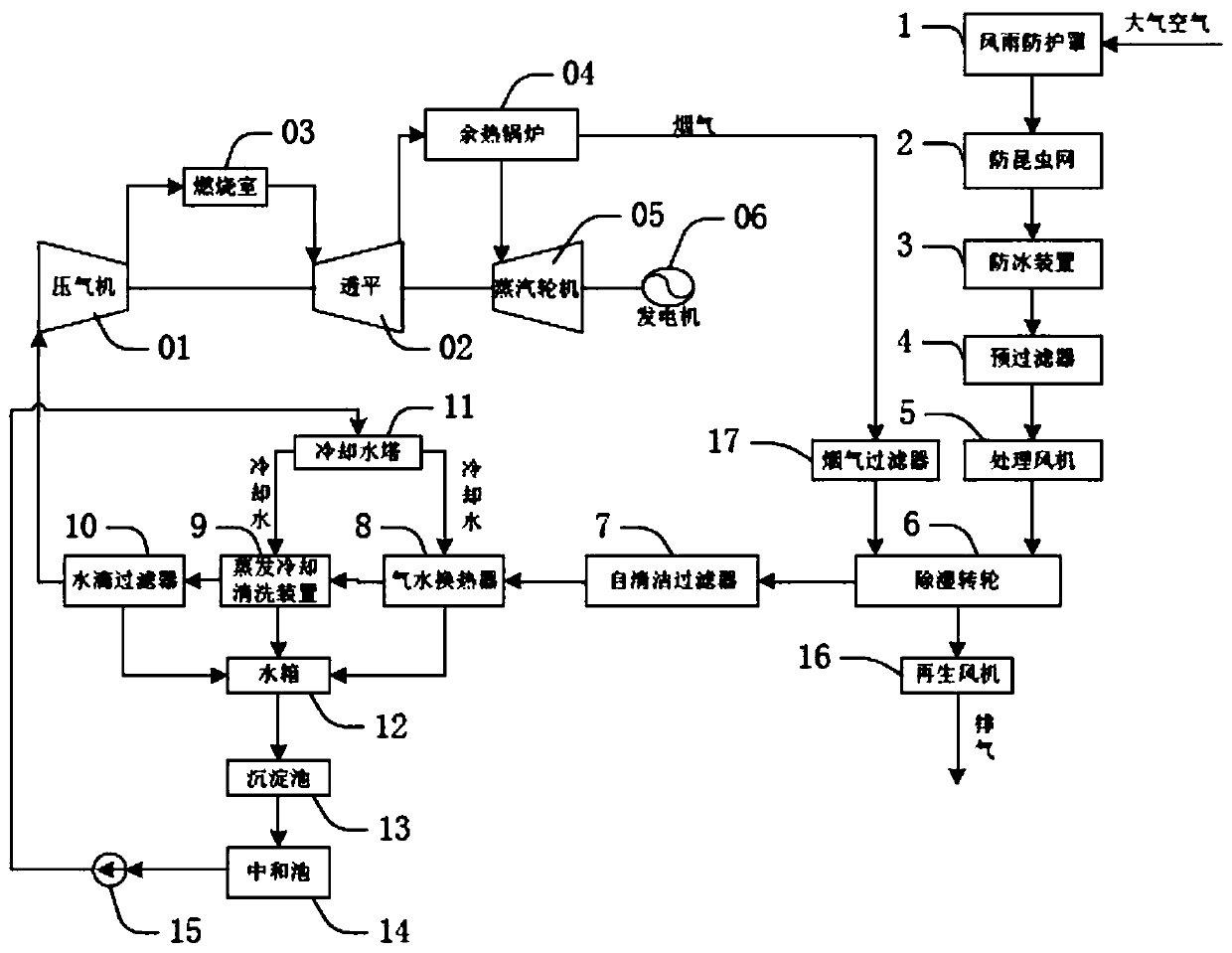

[0037] see figure 1 and figure 2 , the gas turbine air intake treatment system integrating pollutant cleaning, filtering and evaporative cooling is set at the intake end of the gas-steam combined cycle power unit composed of gas turbine, steam turbine 05, waste heat boiler 04 and generator 06. The gas turbine is composed of compressed gas The compressor 01, the combustion chamber 03 and the turbine 02 are composed of the gas-steam combined cycle power generation unit, and the intake end of the gas-steam combined cycle generator set is set on the compressor 01.

[0038] Inlet Cooling Improves Performance of Gas-Steam Combined Cycle Power Plants: Gas turbines are constant-volume mechanical power plants, and the mass flow of air depends on the air density. The air temperature at the inlet of the compressor decreases, the density increases, the mass flow rate of the air flowing through the gas turbine increases, and the working capacity of the gas turbine increases accordingly. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com