Method for dissolving out to extract lithium from defluorinated lepidolite in pipeline

A lepidolite and defluorination technology, which is applied in the field of lithium extraction from ore, can solve the problem of inability to efficiently extract lithium in lepidolite, and achieve the effects of low heat loss, low energy consumption and fast flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

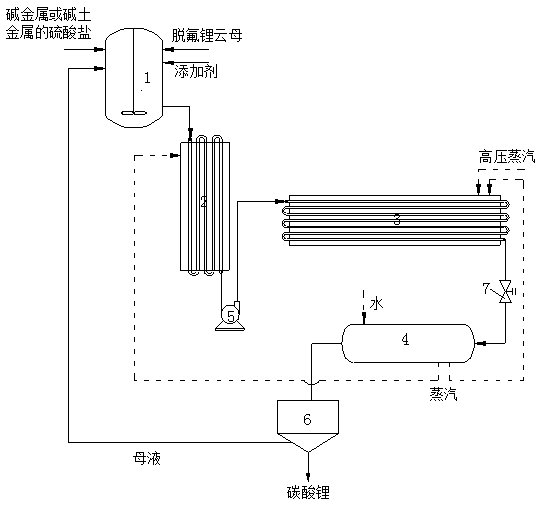

Image

Examples

Embodiment 1

[0025] The natural lepidolite concentrate with a lithium oxide content of 4.5wt% is defluorinated by high-temperature roasting, and then crushed to a particle size of D 90 =100 μm, the obtained defluorinated lepidolite ore powder, sodium sulfate, additive CaO are slurried in the mixing tank with water in a weight ratio of 1:1:0.3, the solid-liquid weight ratio of the slurry is 1:8, and the slurry is in The preheater is preheated to a temperature of 90°C, and then pumped into the pipeline reactor, heated by a jacket or directly injected with pressurized steam for high-temperature and high-pressure dissolution reaction. The flow rate of the slurry is 5m / min, and the reaction temperature is 230°C. ℃, the reaction pressure is 2.8MPa, and the reaction time is 240min. After the reaction is completed, the slurry is cooled to 30-60℃ by heat exchange through a heat exchanger, and then solid-liquid separation is carried out to obtain lithium sulfate, sodium sulfate, potassium sulfate, an...

Embodiment 2

[0027] The natural lepidolite concentrate with a lithium oxide content of 5wt% is defluorinated by high-temperature roasting, and then crushed to a particle size of D 90 =75 μm, the obtained defluorinated lepidolite ore powder, potassium sulfate, additive CaO are slurried in the mixing tank with water at a weight ratio of 1:1:0.3, and the solid-to-liquid weight ratio of the slurry is 1:7. The preheater is preheated to a temperature of 80°C and then pumped into the pipeline reactor to heat through a jacket or directly into high-pressure steam for high-temperature and high-pressure dissolution reaction. The flow rate of the slurry is 0.5m / min, and the reaction temperature is 220°C. ℃, the reaction pressure is 2.4MPa, and the reaction time is 300min. After the reaction is completed, the slurry is cooled to 30-60℃ by heat exchange through a heat exchanger, and then solid-liquid separation is carried out to obtain lithium sulfate, sodium sulfate, potassium sulfate, and sulfuric acid...

Embodiment 3

[0029] The natural lepidolite concentrate with a lithium oxide content of 4.5wt% is defluorinated by high-temperature roasting, and then crushed to a particle size of D 90 =75 μm, obtained defluorinated lepidolite powder, sodium sulfate and calcium sulfate, additive NaHCO 3 Slurry is mixed with water in the mixing tank at a weight ratio of 1:1.5:0.1. The solid-to-liquid weight ratio of the slurry is 1:8. The slurry is pumped into the pipeline reactor and heated by jacket or directly by high-pressure steam. Carry out high temperature and high pressure dissolution reaction, the flow rate of the slurry is 4m / min, the reaction temperature is 240°C, the reaction pressure is 3.4MPa, and the reaction time is 300min. After the reaction is completed, the slurry is cooled to 40-80°C by heat exchange through a heat exchanger , and then carry out solid-liquid separation to obtain a filtrate containing lithium sulfate, sodium sulfate, potassium sulfate, rubidium sulfate and cesium sulfate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com