System and method capable of increasing protein extraction effect

A protein and extraction technology, applied in the system field of improving the protein extraction effect, can solve the problems of poor protein particle stability, low protein dissolution efficiency, poor extraction effect, etc., to achieve improved protein separation effect, shortened extraction time, and increased stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

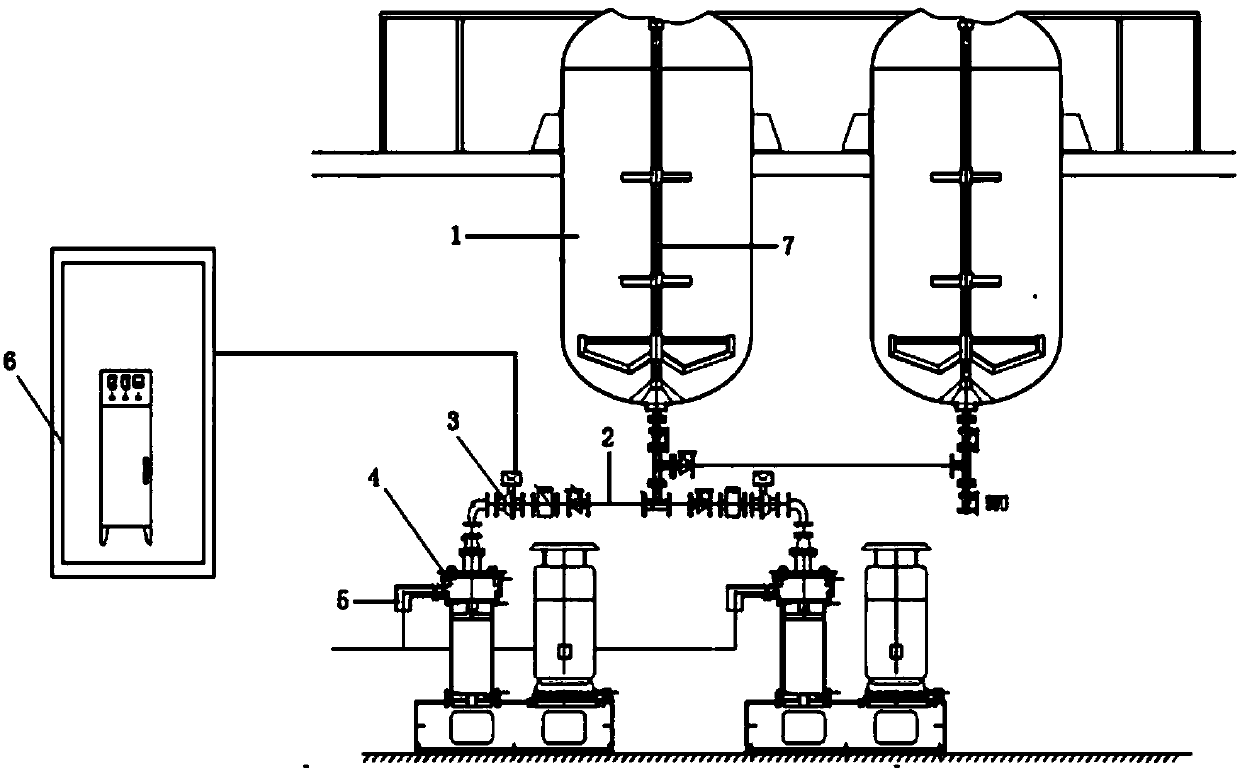

[0046] A system capable of improving the protein extraction effect, comprising two mixing tanks 1 and two ultra-fine grinding equipment a4; the feed ports at the upper end of each ultra-fine grinding equipment a4 are respectively connected to pipelines 2 and connected to the two mixing tanks 1 lower end. Pneumatic ball valves 3 are respectively arranged on the pipelines 2 connecting the two ultra-fine pulverizing equipment a4 respectively. By controlling the pneumatic ball valve 3, the flow direction switching of materials to different ultrafine grinding equipment a4 is realized;

[0047] The stirring tank 1 is provided with a rapid stirring device 7, and the stirring rate is 0-5000r / min; the upper part of the stirring tank 1 is provided with a feeding port. The rapid stirring device 7 is a prior art and can be purchased commercially; it can be installed in the stirring tank 1 according to the prior art.

[0048]The superfine pulverization equipment a4 is provided with a dis...

Embodiment 2

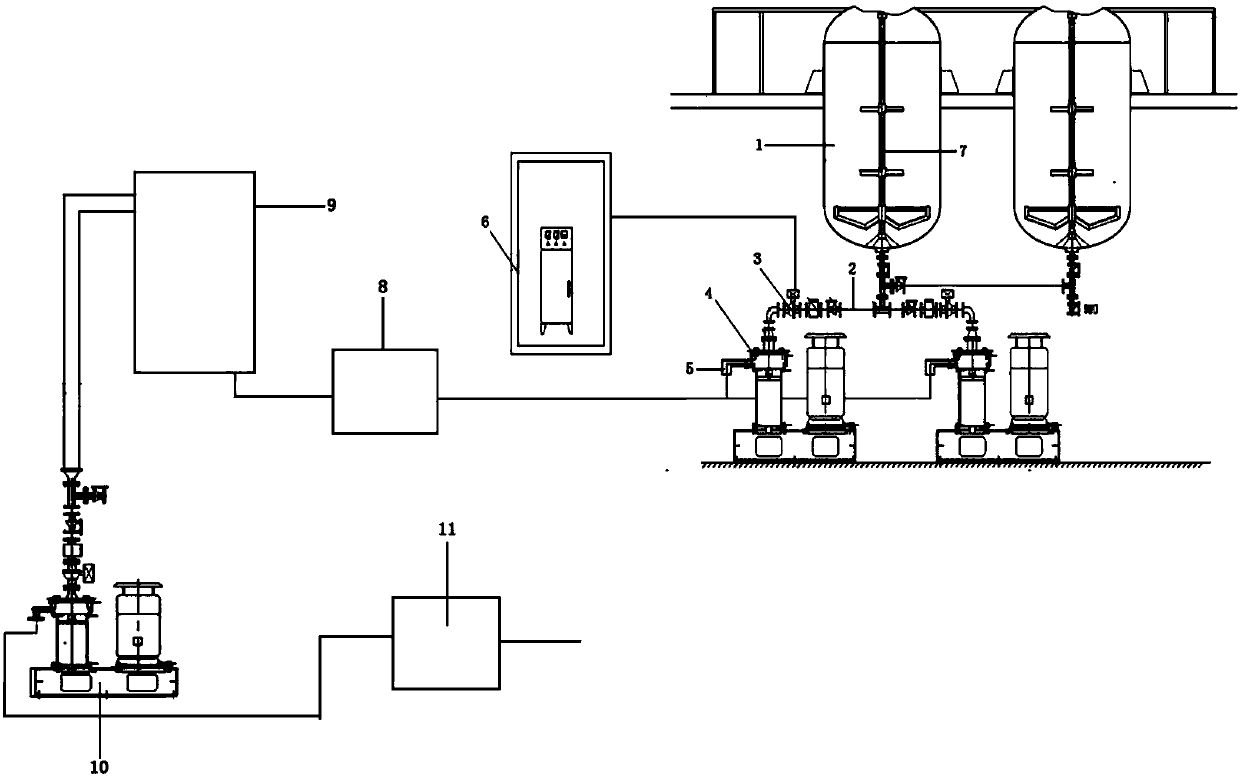

[0051] A system capable of improving the protein extraction effect, comprising two mixing tanks 1 and two ultra-fine grinding equipment a4; the feed ports at the upper end of each ultra-fine grinding equipment a4 are respectively connected to pipelines 2 and connected to the two mixing tanks 1 lower end. Pneumatic ball valves 3 are respectively arranged on the pipelines 2 connecting the two ultra-fine pulverizing equipment a4 respectively. By controlling the pneumatic ball valve 3, the flow direction switching of materials to different ultrafine grinding equipment a4 is realized;

[0052] The stirring tank 1 is provided with a rapid stirring device 7, and the stirring rate is 0-5000r / min; the upper part of the stirring tank 1 is provided with a feeding port. The rapid stirring device 7 is a prior art and can be purchased commercially; it can be installed in the stirring tank 1 according to the prior art.

[0053] The superfine pulverization equipment a4 is provided with a di...

Embodiment 3

[0057] Utilize the method for extracting protein by the system described in embodiment 1, comprise steps:

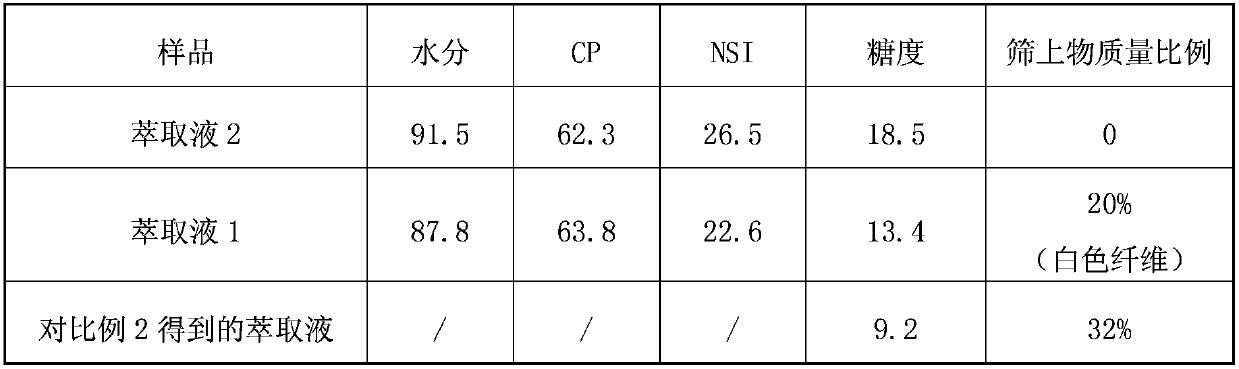

[0058] Add 1000g of soybean meal, 8L of water and 2g of food-grade defoamer into the mixing tank 1, and soak at 30°C for 25 minutes under the stirring of the rapid stirring device 7 (stirring speed is 4500r / min); then remotely control the pneumatic ball valve 3, Make the mixed liquid enter the superfine pulverization equipment a4 through the pipeline 2, and shear and pulverize it at 3000 rpm for 3 minutes in the superfine pulverization equipment with 80 mesh tooth gap, and the shear pulverization efficiency is 0.3m 3 / min, to obtain the extract 1; then in the ultra-fine grinding equipment with 200 mesh tooth gap, shear and grind at 3000 rpm for 3 minutes, the shearing and grinding efficiency is 0.3m 3 / min, the extract 2 was obtained, and its sugar content was measured to be 11.2BX. The extract 2 is separated by separator a to obtain soybean milk and soybean dregs.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com