Modified g-C3N4 based visible light catalyst, and preparation method and application thereof

A photocatalyst and visible light technology, applied in the field of photocatalytic materials, can solve the problems of high cost, low utilization rate of visible light, increase of visible light response range, etc., and achieve the effect of large output, increased visible light response range and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A modified g-C 3 N 4 A preparation method for a visible light-based photocatalyst, comprising the steps of: the photocatalyst is a visible light-responsive g-C 3 N 4 base photocatalyst.

[0046] (1) Preparation of precursor

[0047] Put melamine into a muffle furnace, heat up at a rate of 3°C / min, and burn at 450°C for 4 hours to polymerize melamine at high temperature to form a semiconductor material g-C with a wide band gap tris-triazine structure 3 N 4 , and then washed and dried to remove other substances in the system.

[0048] (2) Preparation of reducing materials

[0049] The material obtained in (1) was mixed with NaBH 4 According to the mass ratio of 1:5, it is mixed and ground into a tube furnace, reduced for 30 minutes under nitrogen at 370°C, washed with water for 3 times, and dried to obtain the modified g-C 3 N 4 base photocatalyst.

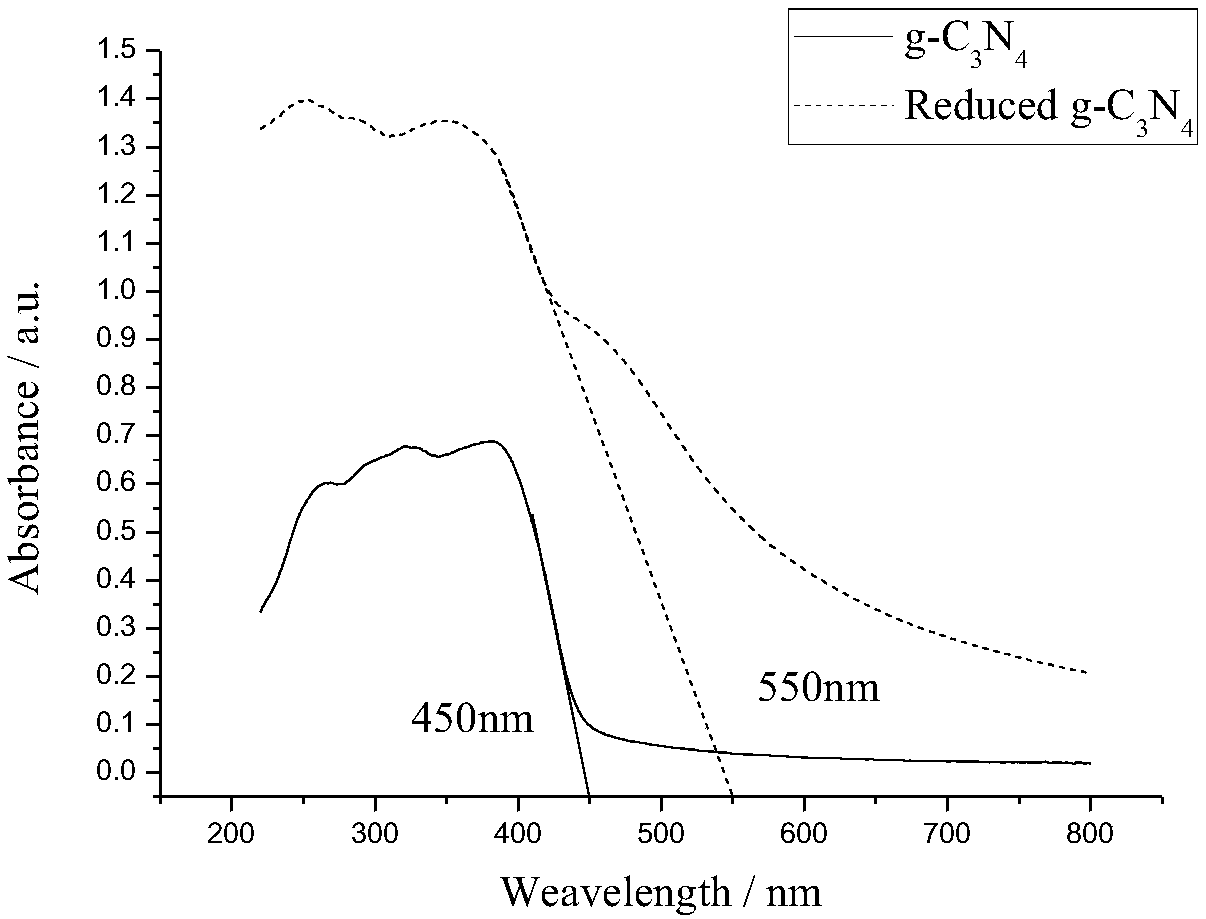

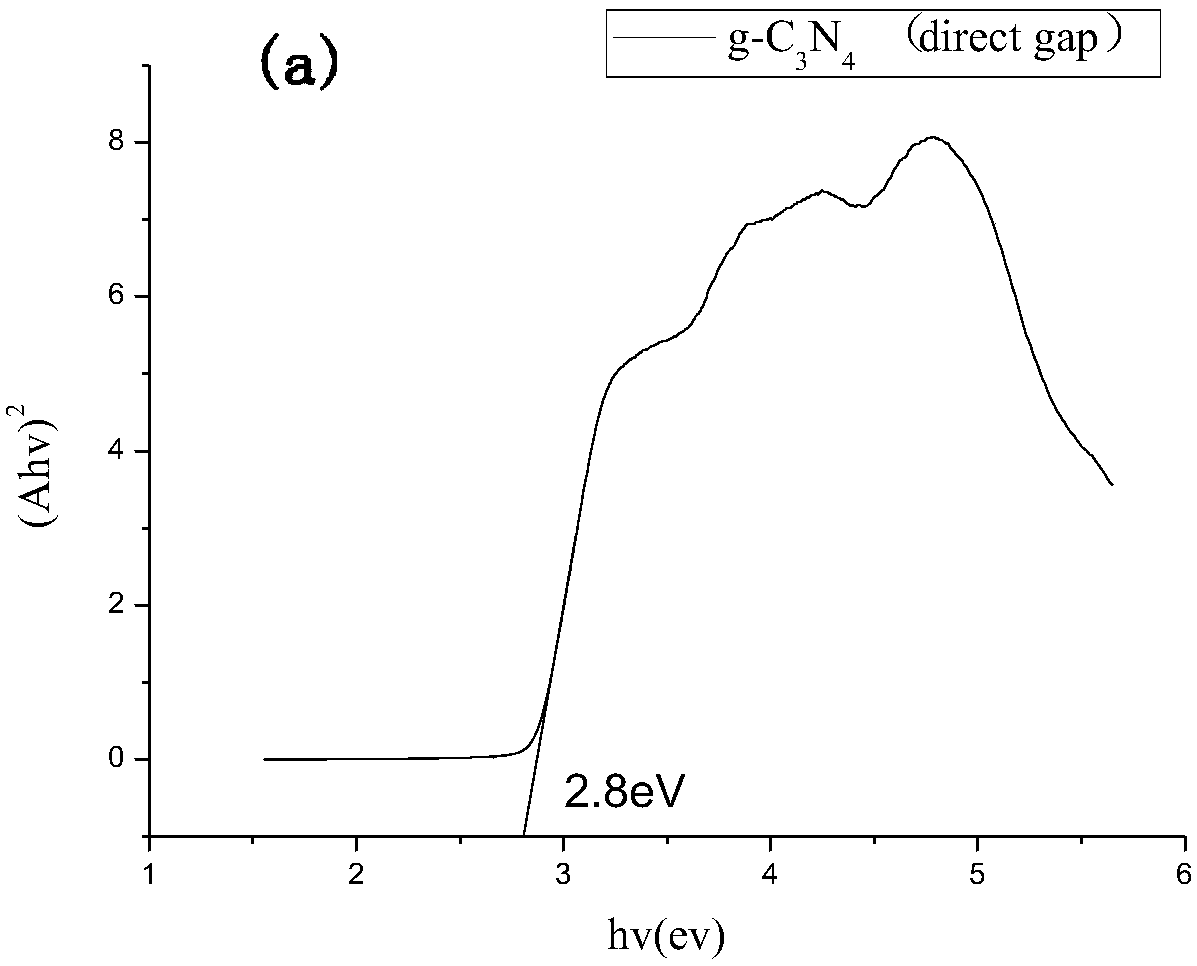

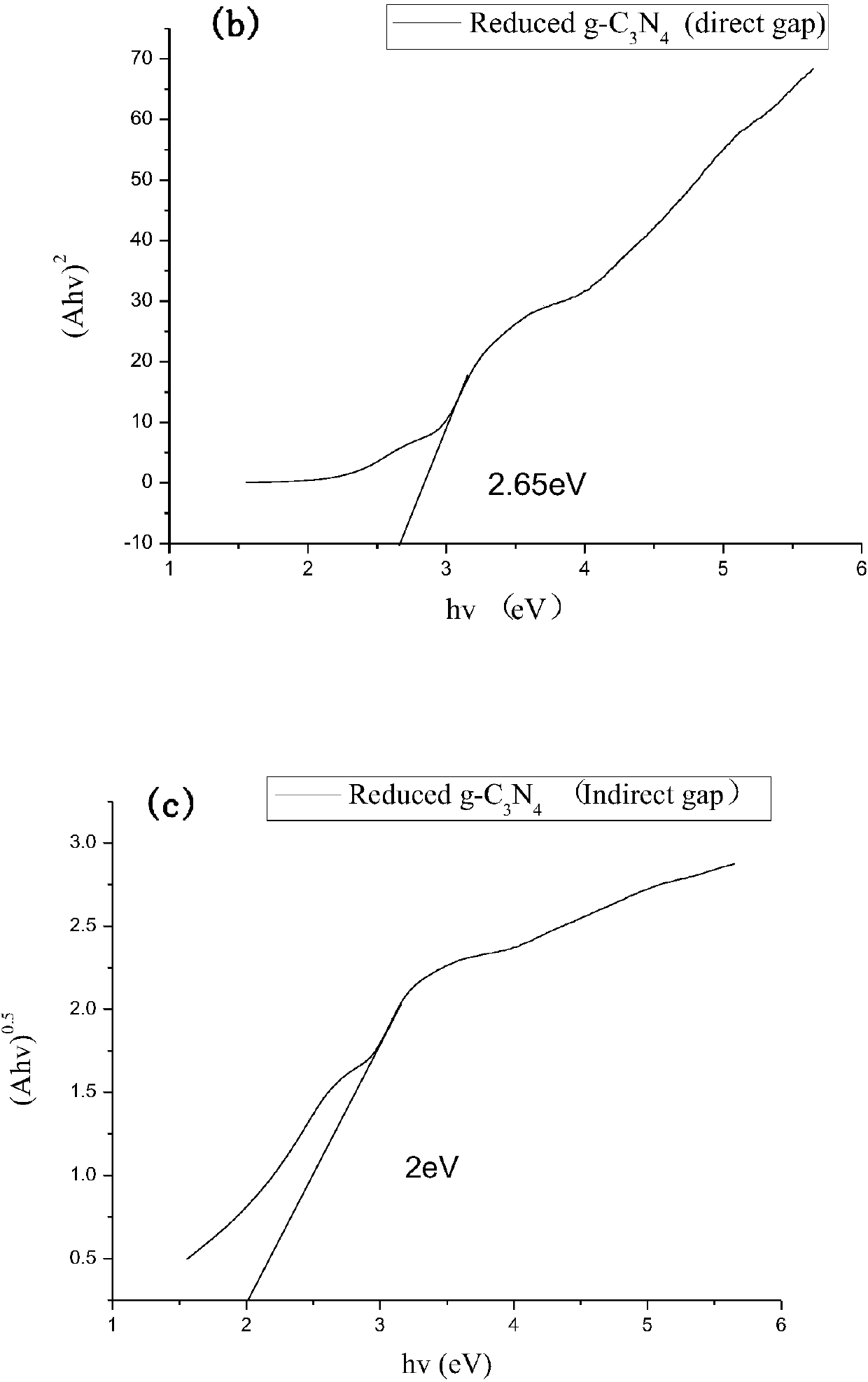

[0050] Carry out result analysis to the photocatalyst prepared in this embodiment: the g-C mentioned below 3 N ...

Embodiment 2

[0065] A modified g-C 3 N 4 A preparation method for a visible light-based photocatalyst, comprising the steps of: the photocatalyst is a visible light-responsive g-C 3 N 4 base photocatalyst.

[0066] (1) Preparation of precursor

[0067] Put melamine into a muffle furnace, heat up at a rate of 15°C / min, and burn at 400°C for 4 hours to polymerize melamine at high temperature to form a semiconductor material with a wide band gap g-C 3 N 4 , and then washed and dried to remove other substances in the system.

[0068] (2) Preparation of reducing materials

[0069] The material obtained in (1) was mixed with NaBH 4 According to the mass ratio of 1:2, put it into a tube furnace after mixing and grinding, and reduce it under nitrogen at 400°C for 40 minutes, then wash the reduced material for 3 times, and dry it to obtain the modified g-C 3 N 4 base photocatalyst.

Embodiment 3

[0071] A modified g-C 3 N 4 A preparation method for a visible light-based photocatalyst, comprising the steps of: the photocatalyst is a visible light-responsive g-C 3 N 4 base photocatalyst.

[0072] (1) Preparation of precursor

[0073] Put melamine into a muffle furnace, heat up at a rate of 5°C / min, and burn at 500°C for 4 hours to polymerize melamine at high temperature to form a semiconductor material with a wide band gap g-C 3 N 4 , and then washed and dried to remove other substances in the system.

[0074] (2) Preparation of reducing materials

[0075] The material obtained in (1) was mixed with NaBH 4 Mix and grind according to the mass ratio of 1:6, put it into a tube furnace, reduce it under nitrogen at 300°C for 20 minutes, wash the reduced material three times, and dry it to obtain the modified g-C 3 N 4 base photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com