Horizontal water-pipe-type-structure steam generator

A steam generator and water pipe technology, which is applied to water-tube steam boilers, steam generation, steam boilers, etc., can solve the problems of unfavorable overall volume of the generator, easy scaling of water pipes, low thermal efficiency, etc., and achieves simple and easy operation and maintenance. The effect of improving heat exchange efficiency and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

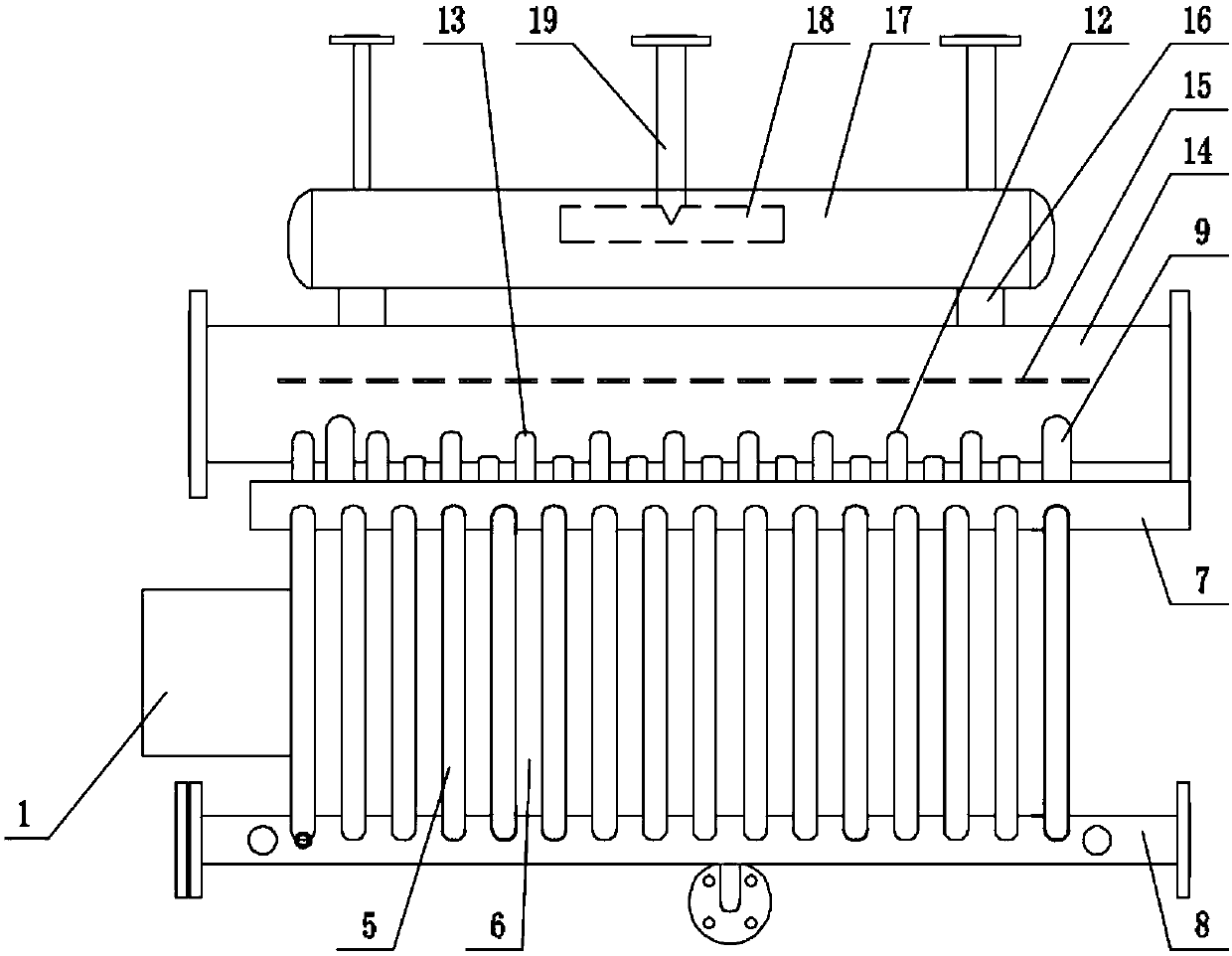

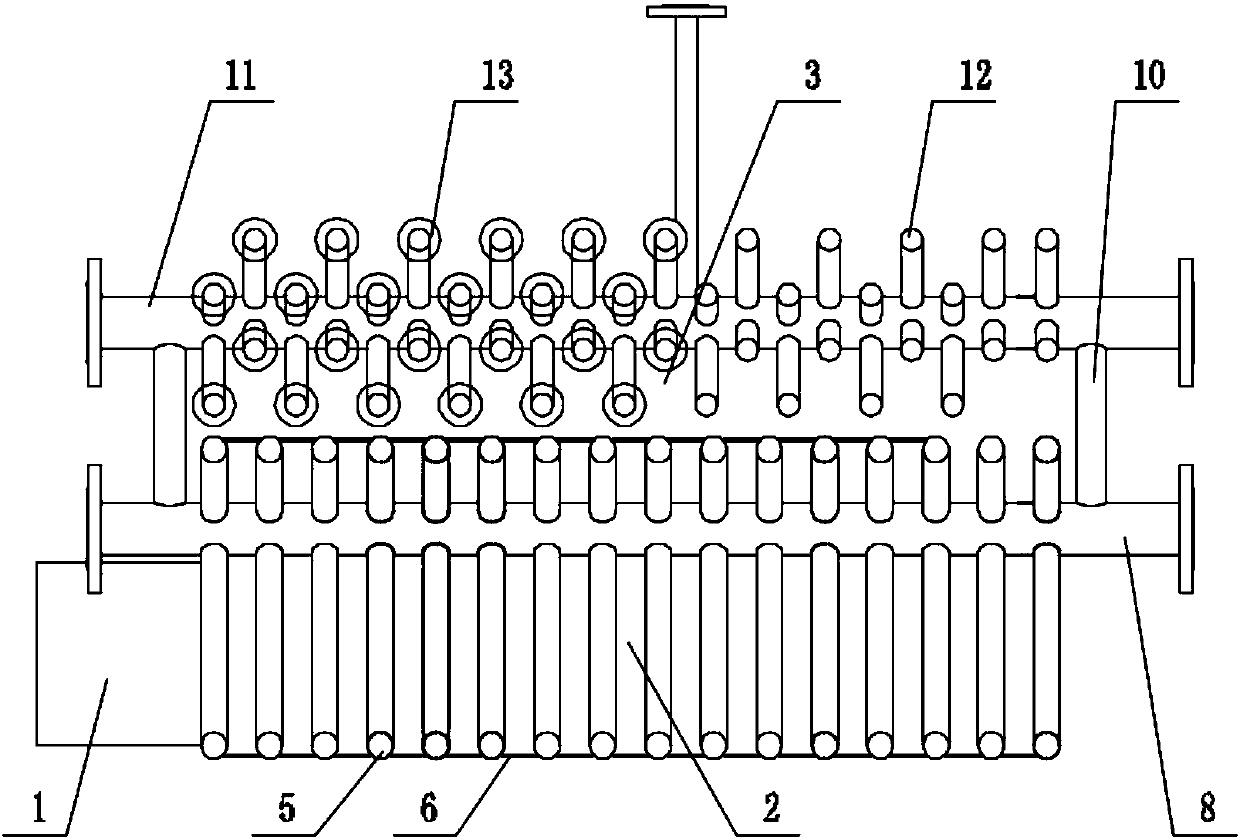

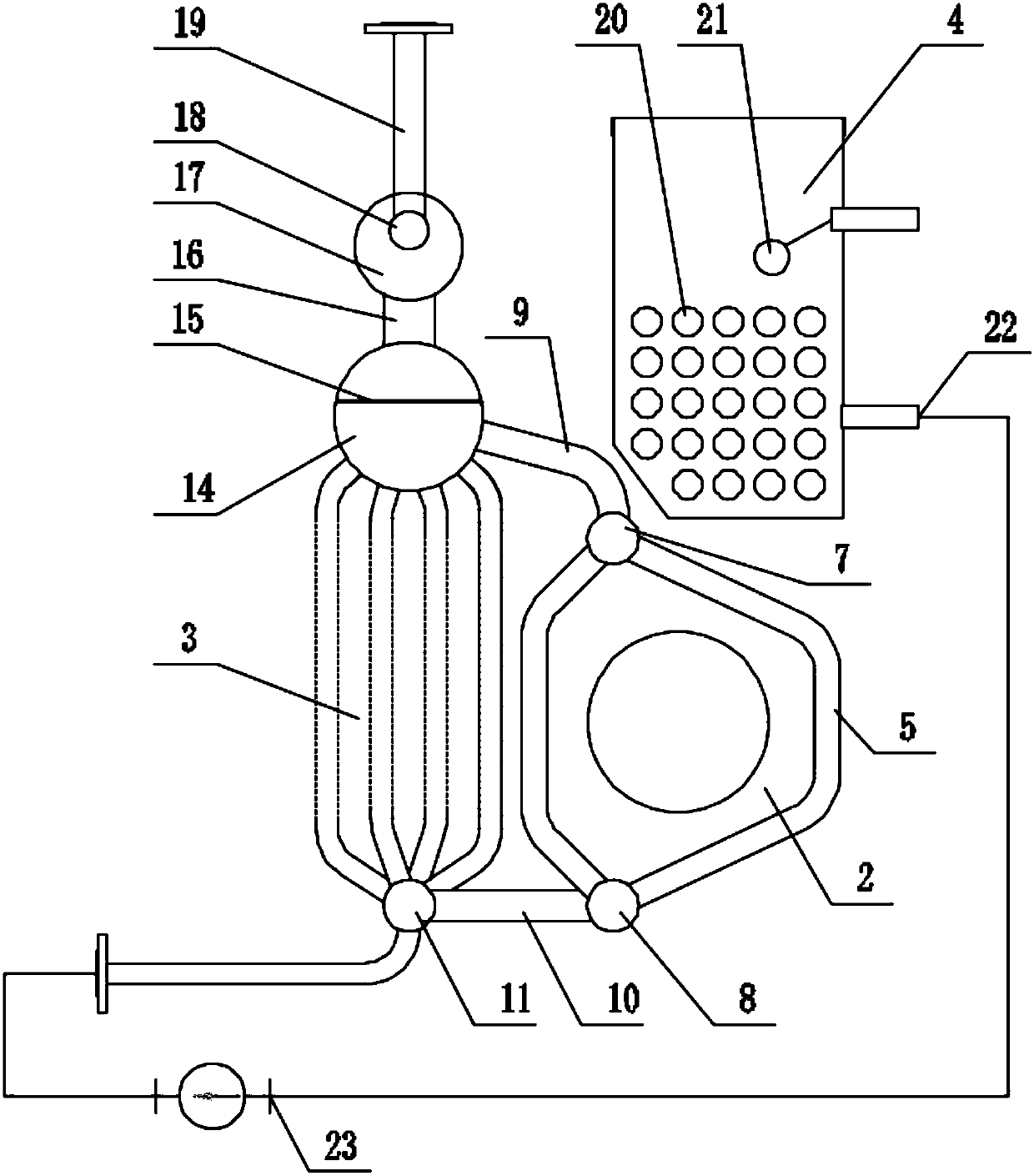

[0029] Such as Figure 1-3 As shown, the steam generator with a horizontal water tube structure in this embodiment includes a membrane hearth 2, a convection heating surface 3, a normal pressure economizer 4, a water supply system and a burner, and the convection heating surface 3 is composed of light pipes 12. The light tube convection heating surface and the finned tube convection heating surface composed of finned tubes 13,.

[0030] The atmospheric pressure economizer 4 is equipped with a plurality of high-efficiency heat-exchange threaded smoke pipes 20 arranged in a matrix. The high-efficiency heat-exchange threaded smoke pipes 20 are used as the heating surface to recover the waste heat in the flue gas. It is connected to the atmosphere and is safe and reliable. The water supply system is used to provide softened water, which is heated and deoxidized by the normal pressure economizer 4 to reduce the dissolved oxygen content in the softened water and prevent it from corr...

Embodiment 2

[0036] The steam generator with a horizontal water tube structure in this embodiment includes a membrane hearth, a convection heating surface, an atmospheric economizer, a water supply system, and a burner; the convection heating surface is a heating surface composed of bare tubes and finned tubes.

[0037] The atmospheric pressure economizer is equipped with a serpentine high-efficiency heat exchange threaded smoke pipe, which serves as the heating surface, which increases the heating area and improves the utilization rate of waste heat; the water supply system is used to provide softened water, soften The water is heated and deoxidized by the normal pressure economizer to reduce the dissolved oxygen content in the softened water and prevent it from corroding and scaling the pipeline; the water level in the normal pressure economizer is automatically controlled by the float valve to realize automatic water intake; There is also a water-shortage protection device inside the pre...

Embodiment 3

[0044] The steam generator with a horizontal water tube structure in this embodiment includes a membrane hearth, a convection heating surface, an atmospheric pressure economizer, a water supply system, and a burner; the convection heating surface is a single bare tube heating surface or a finned tube heating surface .

[0045] The atmospheric pressure economizer is equipped with a serpentine high-efficiency heat exchange threaded smoke pipe, which serves as the heating surface, which increases the heating area and improves the utilization rate of waste heat; the water supply system is used to provide softened water, soften The water is heated and deoxidized by the normal pressure economizer to reduce the dissolved oxygen content in the softened water and prevent it from corroding and scaling the pipeline; the water level in the normal pressure economizer is automatically controlled by the float valve to realize automatic water intake; There is also a water-shortage protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com