Sulfate polymyxin B crystal and preparation method thereof

A technology of polymyxin sulfate and polymyxin, applied in the direction of preparation methods of polymyxin and peptides, chemical instruments and methods, etc., can solve the problems of crystallized precipitates that are easy to stick into agglomerates, clarity and purity Advanced problems, to achieve the effect suitable for large-scale industrial production, good clarity and purity, low hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take 5L of polymyxin B fermented liquid, the potency is 1.8g / L, add oxalic acid solid to adjust the pH to 1.8. After stirring for 30 minutes, add 250g of diatomaceous earth, continue to stir for 30 minutes, then filter with a plate frame, wash with water until the titer is less than 0.2g / L, stop filtering, and obtain 7.1L of filtrate, which contains 8.5g of polymyxa Prime B. The filtrate was adjusted to pH 6.7 with 2M sodium hydroxide, then loaded into a chromatographic column containing 60 ml of LXD-135 weakly acidic ion exchange resin, and adsorbed through the column. After adsorption is complete, adopt the water washing of 2-3 times volume by the volume meter of LXD-135 weakly acidic ion-exchange resin until the effluent is colorless, then desorb with 0.2M sulfuric acid aqueous solution, obtain desorption liquid 800ml (containing polymyxa sulfate Vitamin B 7.4g). The pH of the desorbed solution was adjusted to 6.5 with 2M sodium hydroxide solution, and then loaded ...

Embodiment 2

[0049] Get polymyxin B fermented liquid 5L, titer is 1.8g / L, then prepare desorption liquid according to the technique of embodiment 1. The desorbed solution obtained in this embodiment is a concentrated solution with a volume of 50 ml (containing polymyxin B sulfate 5.3 g) after concentration. Start stirring, and slowly add ethyl acetate dropwise to the concentrated solution until the solution becomes turbid, then stop adding ethyl acetate dropwise. Then lower the temperature to 0-5°C, stir until the solid precipitates, and then continue to add the remaining ethyl acetate dropwise until a total of 3 times the amount of ethyl acetate based on the volume of the concentrated solution is added dropwise. Stirring was then continued at 0-5°C for 7 hours, and the solid was filtered off. The filtered solid was vacuum-dried at 60°C for 3 hours to obtain 4.82g of a white solid, with a crystallization yield of 91%, a purity of 89.58%, a clarity test result of No. 1, and a titer of 8355...

Embodiment 3

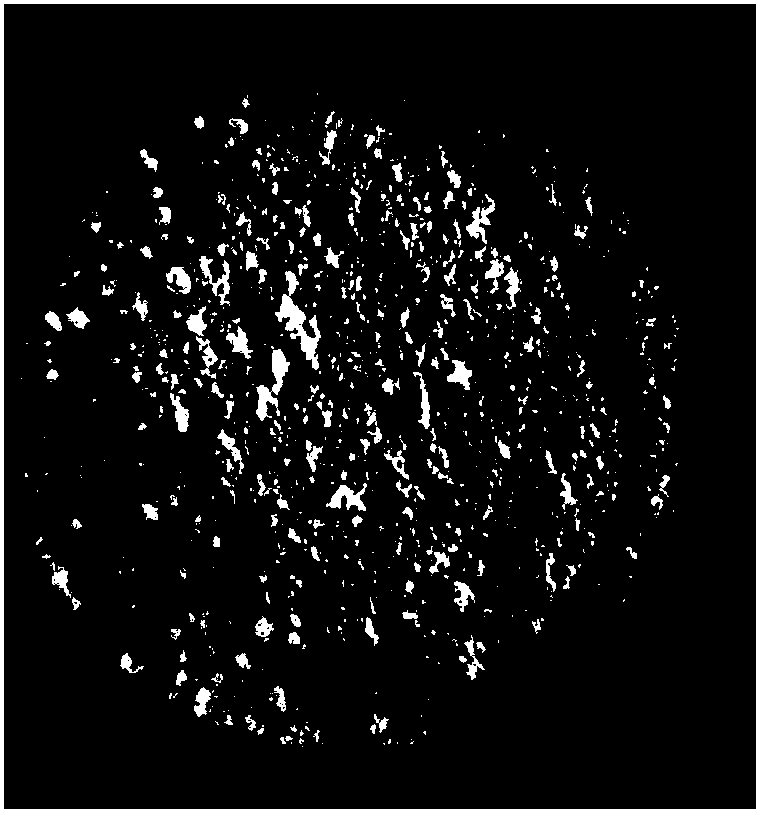

[0051] Get polymyxin B fermented liquid 7L, titer is 1.8g / L, then prepare desorption liquid according to the technique of embodiment 1. The desorbed solution in this example was concentrated to obtain a concentrated solution (containing polymyxin B sulfate 6.7 g) with a volume of 85 ml. Start stirring, and slowly drop acetone into the concentrated solution until the solution becomes turbid, then stop adding acetone. Then lower the temperature to 0-5° C., stir until the solid precipitates, and then continue to drop the remaining acetone until a total of 3.5 times the amount of acetone based on the volume of the concentrated solution is added dropwise. Then continue stirring at 0-5°C for 6 hours, filter the solid, and dry the filtered solid in vacuum at 60°C for 4 hours to obtain 5.83g of white solid with a crystallization yield of 87%, a purity of 90.98%, and a clear Degree No. 1, the potency determined by the tube-and-dish method is 8100U / g. Under the same conditions, the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com