Bio-based wheat straw polypropylene composite material and preparation method thereof

A wheat straw and composite material technology, which is applied in the field of bio-based wheat straw polypropylene composite materials and its preparation, can solve the problems of increased material or product cost, material performance deterioration, environmental pollution, etc., and achieves increased surface energy, ease of processing , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

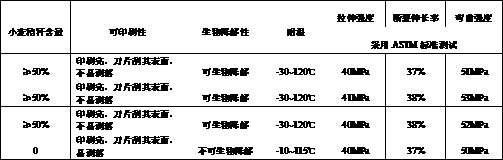

Examples

Embodiment 1

[0030] A bio-based wheat straw polypropylene composite material, which is composed of the following components by mass fraction: PP material 20%, PE material 15%, wheat straw 55%, ethylene-octene copolymer 4%, maleic anhydride grafted polypropylene 6%.

[0031] The preparation steps of the bio-based wheat straw polypropylene composite material are as follows:

[0032] A. Wash and crush 1Kg of straw and add it to 2L of sodium hydroxide solution with a mass fraction of 2%, soak it at 40°C for 8 hours, and add a solubility of 0.5mol L -1 acetic acid solution to a pH of 7; clean the neutralized stalks, place them in a hydrothermal reactor at a constant temperature of 120°C for 5 hours, cool to room temperature, take them out, wash them with water, and dry them in vacuum to obtain 0.85 Kg of treated stalks;

[0033] B. Weigh 0.85Kg of treated plant straw, 0.3Kg of PP material, 0.25Kg of PE material, 0.06Kg of ethylene-octene copolymer and 0.09Kg of maleic anhydride grafted polypro...

Embodiment 2

[0035] A bio-based wheat straw polypropylene composite material, which consists of the following components by mass fraction: PP material 25%, PE material 15%, wheat straw 52%, ethylene-vinyl acetate copolymer 3%, maleic anhydride grafted polypropylene 5%.

[0036] The preparation steps of the bio-based wheat straw polypropylene composite material are as follows:

[0037] A. Wash and crush 2Kg of straw and add it to 4L of 3% sodium hydroxide solution, soak it at 45°C for 10 hours, and add a solubility of 0.8mol L -1 acetic acid solution to a pH of 7; clean the neutralized stalks, place them in a hydrothermal reactor at a constant temperature of 140°C for 8 hours, cool to room temperature, take them out for washing, and vacuum dry to obtain 1.8Kg of treated stalks;

[0038]B. Weigh 1.8Kg of treated plant straw, 0.9Kg of PP material, 0.52Kg of PE material, 0.1Kg of ethylene-vinyl acetate copolymer and 0.18Kg of maleic anhydride grafted polypropylene according to the mass ratio ...

Embodiment 3

[0040] A bio-based wheat straw polypropylene composite material, which consists of the following components by mass fraction: PP material 26%, PE material 10%, wheat straw 58%, ethylene-butene copolymer 2%, maleic anhydride grafted polypropylene 4%.

[0041] The preparation steps of the bio-based wheat straw polypropylene composite material are as follows:

[0042] A. Wash and crush 2Kg of straw and add it to 4L of 4% sodium hydroxide solution, soak it at 50°C for 15 hours, and add a solubility of 1.0 mol L -1 acetic acid solution to a pH of 7; clean the neutralized stalks, place them in a hydrothermal reactor at a constant temperature of 150°C for 10 hours, cool to room temperature, take them out, wash them with water, and dry them in vacuum to obtain 1.8Kg of treated stalks;

[0043] B. Weigh 1.8Kg of treated plant straw, 0.8Kg of PP material, 0.32Kg of PE material, 0.06Kg of ethylene-butene copolymer and 0.12Kg of maleic anhydride grafted polypropylene wax according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com