A kind of ceramic grinding fluid and preparation method thereof

A technology of grinding fluid and ceramics, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of large sintering shrinkage, fragility, and low yield, achieve good anti-wear and anti-friction performance, and simple preparation process , good effect of non-foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

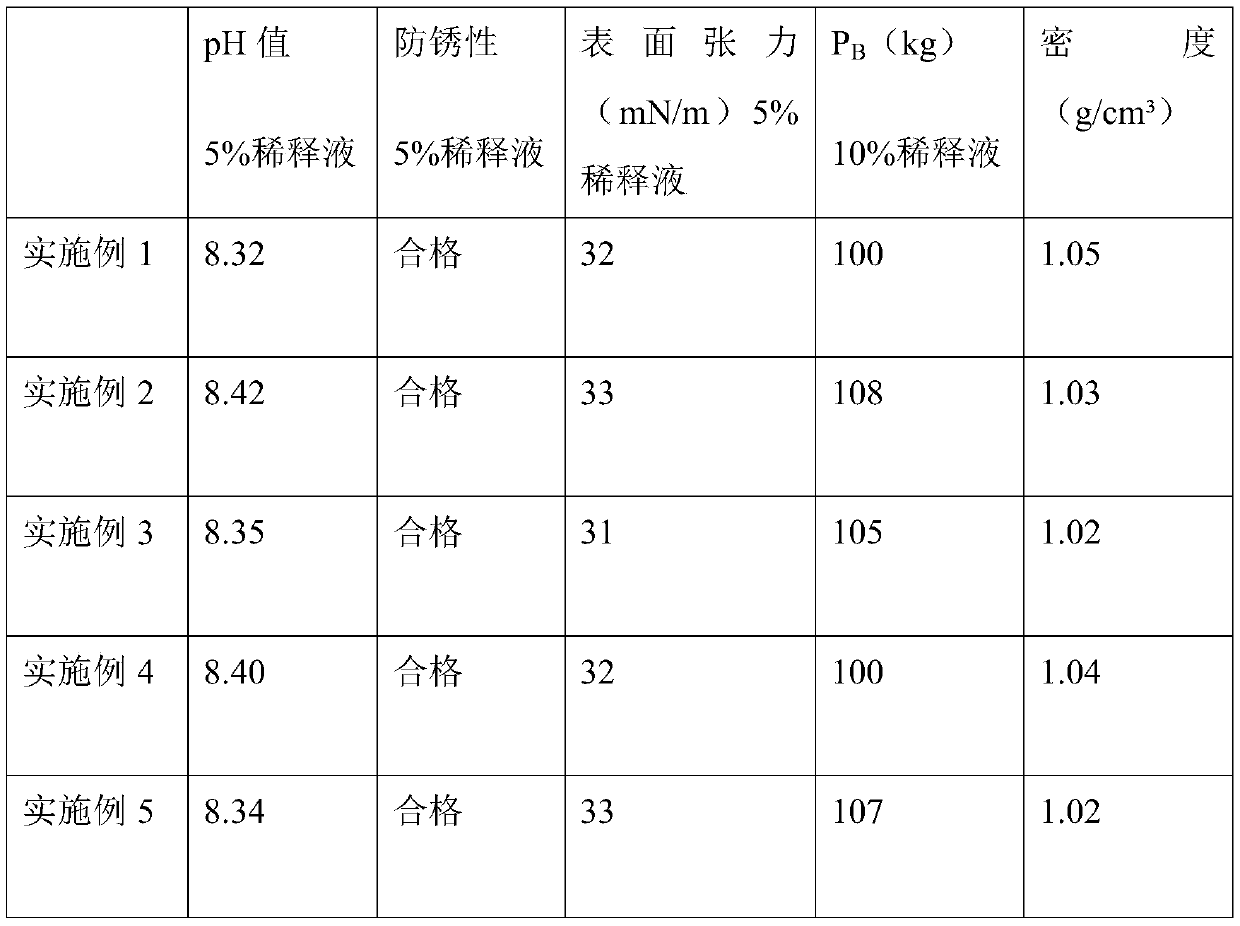

Examples

preparation example Construction

[0030] According to another aspect of the present invention, also provide the preparation method of described grinding liquid, it comprises following preparation steps:

[0031] 1) Stir and react the antirust agent and pH regulator in the above weight percentage at 70-90°C at a speed of 20-40r / min for 2-4h until the two are dissolved and mixed evenly, and cooled naturally to obtain a mixed solution A ,spare;

[0032] 2) Stir and mix the lubricant and wetting agent in the above weight percentage at room temperature at a speed of 60-80r / min to obtain a mixed solution B for later use;

[0033] 3) Stir and mix the deionized water and the anti-wear agent in the above weight percentage at room temperature at a speed of 60-80r / min to obtain a mixed solution C for later use;

[0034] 4) Stir and mix the mixed solution A, mixed solution B and mixed solution C obtained in step 1), step 2) and step 3) at room temperature at a speed of 60-80r / min, and filter to obtain the present inventi...

Embodiment 1

[0036] A ceramic grinding fluid, which is made of the following components by weight percentage: polyetheramine D400: 15%, PEG-8000: 10%, dodecanedioic acid: 10%, ethylene glycol monobutyl ether : 10%, N-methyldiethanolamine: 15%, diglycolamine: 10%, deionized water: 30%. The preparation step of described ceramic grinding liquid comprises:

[0037] 1) Stir the dodecanedioic acid, N-methyldiethanolamine, and diglycolamine at 80°C at a speed of 30r / min in a reactor for 2 hours until all components are dissolved and mixed uniformly , and cooled naturally to obtain a light yellow to yellow transparent mixture A, set aside;

[0038] 2) Stir and mix the polyetheramine D400 and ethylene glycol monobutyl ether in the above weight percentage at room temperature at a speed of 60r / min to obtain a transparent mixed solution B for later use;

[0039] 3) Stir and mix the deionized water and PEG-8000 in the above weight percentage at room temperature at a speed of 60r / min to obtain a trans...

Embodiment 2

[0042] A ceramic grinding fluid, which is made of the following components by weight percentage: polyetheramine D400: 2%, polyetheramine D2000: 3%, PEG-4000: 10%, PEG-8000: 5%, Sebacic acid: 5%, ethylene glycol monobutyl ether: 10%, N-methyldiethanolamine: 10%, 2-amino 2-methyl 1-propanol: 5%, deionized water: 50%; The preparation process of the grinding fluid is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com