Matrix with enhanced bonding strength of surface coating and preparation method of matrix

A combination of strength and surface coating technology, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problems of scratching the surface of other workpieces, peeling off the coating substrate, and increasing the brittleness of the coating, etc. Achieve the effect of enhancing heat insulation effect, improving wear resistance and reducing thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

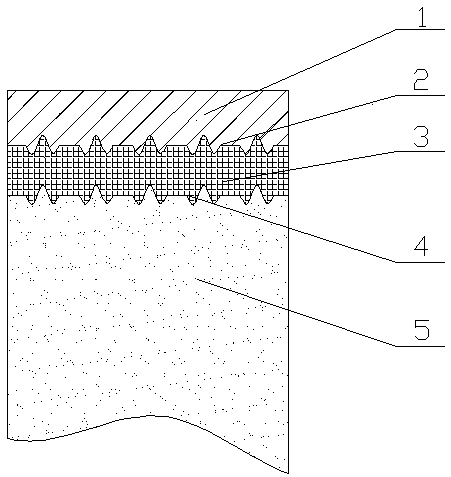

[0026] A substrate with enhanced bonding strength of surface coating, the substrate material is YT15 cemented carbide, and the coating materials are TiC and MoS , The deposition method is ion plating soft coating + chemical vapor deposition hard coating. Concrete preparation steps are as follows:

[0027] (1) Pretreatment: Polish the YT15 cemented carbide substrate material to the mirror surface, remove the surface contamination layer, put it in alcohol and acetone in turn, ultrasonically clean it for 20 minutes each, remove the surface sweat and oil, and dry it fully.

[0028] (2) Use a pulse laser to texture the surface of the base material, and use laser processing to form a concave-convex composite texture morphology; the laser processing parameters are: pulse width 1400μm, pumping voltage 380V, pulse frequency 5Hz, defocus amount 0mm, scan rate 2.5mm / s, auxiliary gas is air, gas pressure 0.5MPa.

[0029] (3) Deposition of TiC: Put the textured substrate on the fixture ...

specific Embodiment 2

[0032] A substrate with enhanced surface coating bonding strength, the substrate material is 45 steel, and the coating materials are TiAlN and TaS 2 , The deposition method is ion plating soft coating + magnetron sputtering hard coating. Concrete preparation steps are as follows:

[0033] (1) Pretreatment: Polish the 45 steel base material to the mirror surface, remove the surface contamination layer, put it in alcohol and acetone in turn, ultrasonically clean it for 20 minutes each, remove the surface sweat and oil, and dry it fully.

[0034] (2) Use a pulse laser to texture the surface of the base material, and use laser processing to form a concave-convex composite texture morphology; the laser processing parameters are: pulse width 1000 μm, pumping voltage 320V, pulse frequency 8Hz, defocus amount 0mm, scan rate 3.0mm / s, auxiliary gas is argon, gas pressure 1.0MPa.

[0035] (3) Deposition of TiAlN: Ar is used as the working gas of the sputtering ion source, and the Ar io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com