Negative-pressure extracting and separating system for organic pollutants in sample and separating method

A technology for organic pollutants and separation systems, applied in the field of negative pressure extraction and separation systems for organic pollutants in samples, can solve the problems of loss of target compounds, affecting analysis results, and high processing costs, reducing analysis costs, and achieving qualitative and quantitative accuracy. The effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

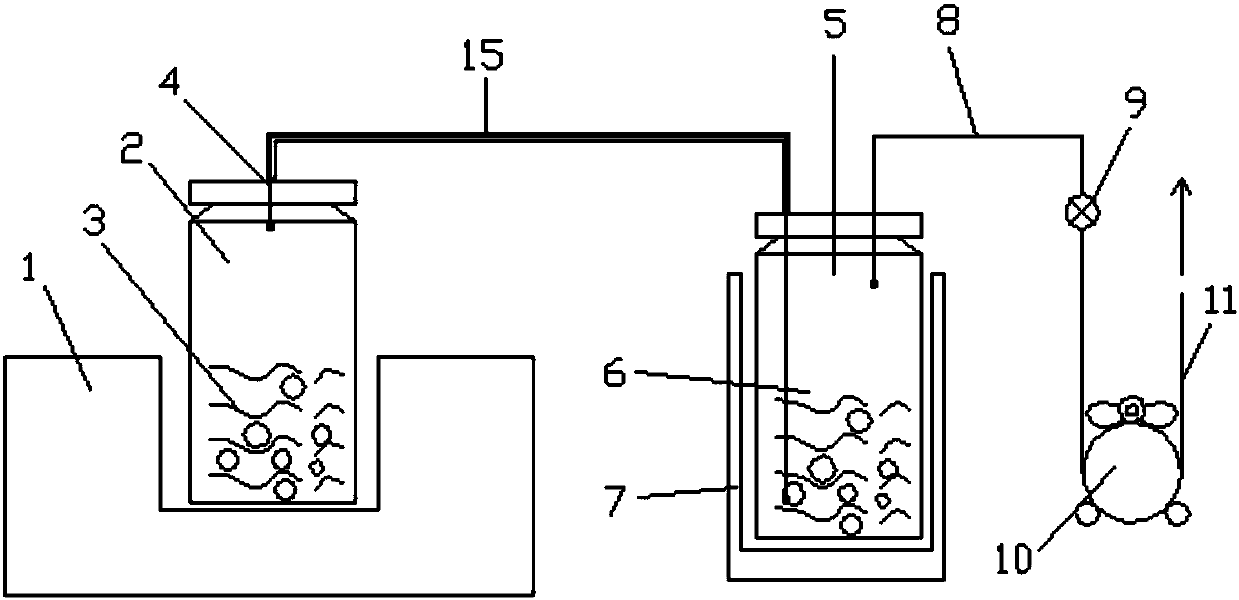

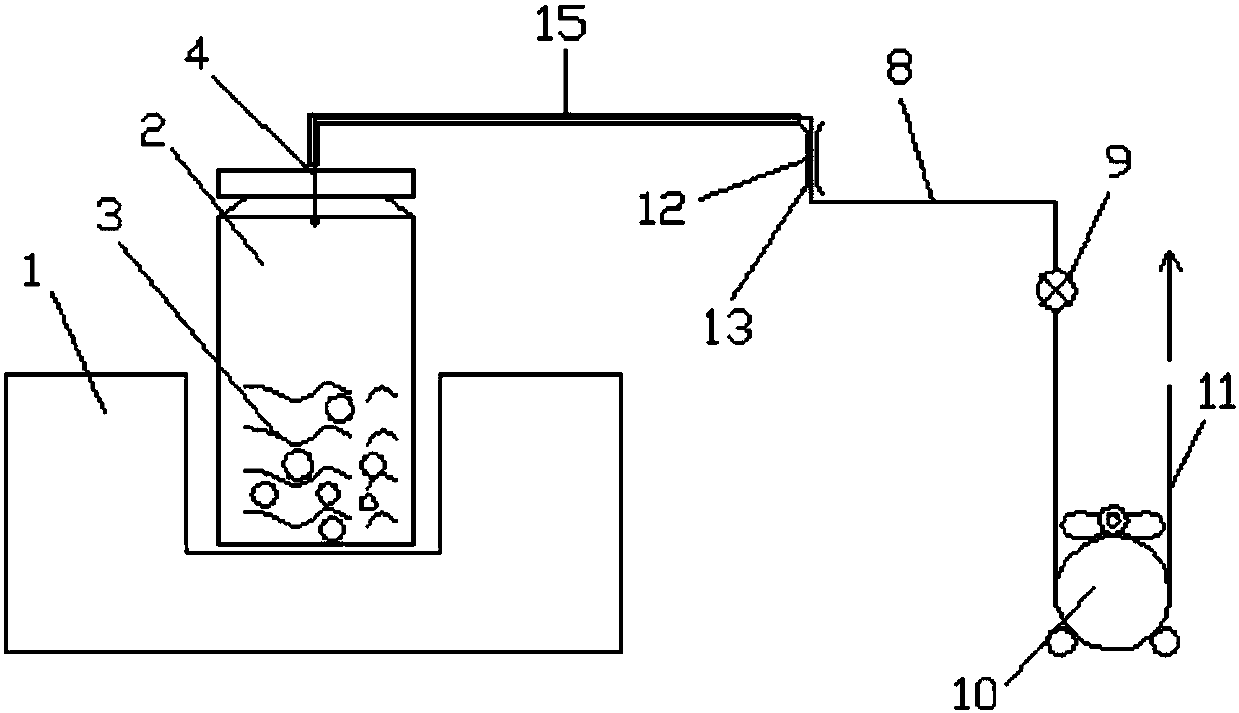

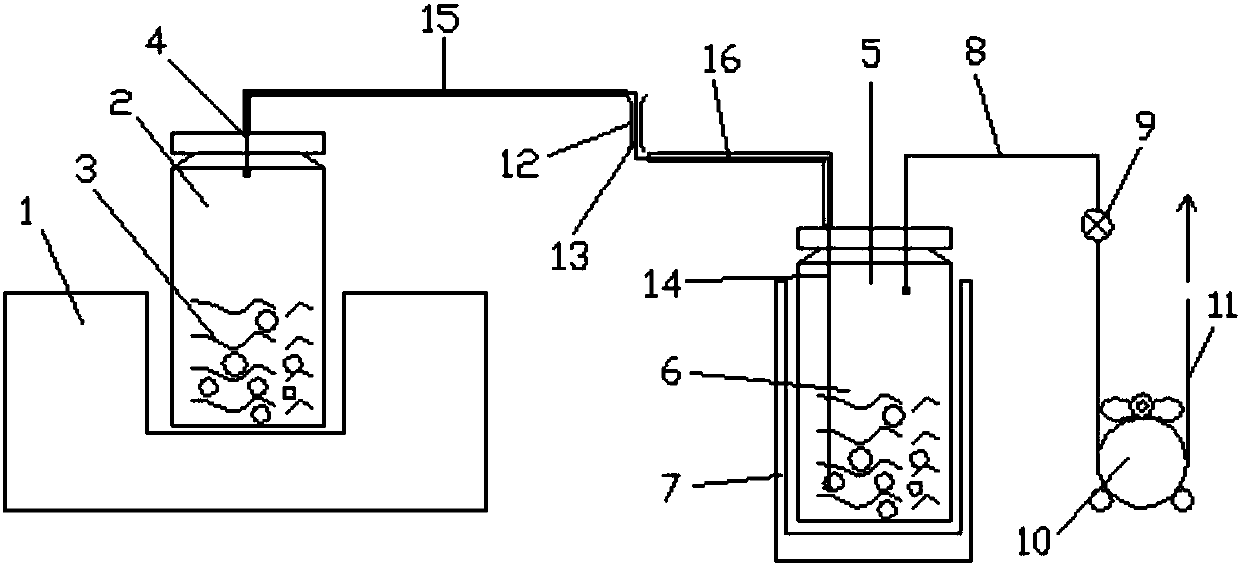

[0039] The negative pressure extraction and separation system for organic pollutants in the sample used in this embodiment is as figure 1 As shown, it includes a sample bottle 2, a first sample transmission line 4, an absorption bottle 5, and a pump 10 connected in sequence. The sample bottle 2 is provided with a sample to be extracted, and the absorption bottle 5 is provided with a liquid adsorbent 6 inside. Specifically, the sample bottle jacket is provided with a sample heater 1, the absorption bottle jacket is provided with a first cooling device 7, and the first sample transfer pipeline 4 is wrapped with a first heating device 15; the sample heater 1 can be electrically heated Heaters or heat exchangers and other common heater structures on the market (because heaters are more common, so I won’t repeat them). The sample heater is set outside the sample bottle 2 to adjust the temperature of the sample bottle. The first heating The device 15 may be a common tubular heater str...

example 1

[0047] This example is to test the negative pressure extraction and separation method of organochlorine pesticides and chlorobenzene compounds in liquid phase (organic solvent phase, water phase) and solid phase (soil).

[0048] 1. Test of negative pressure extraction and separation method for organochlorine pesticides and chlorobenzene compounds with a concentration of 200μg / L in toluene

[0049] ⑴ Standard solution preparation

[0050] Prepare a liquid standard mixture of organochlorine pesticides and chlorobenzene into a mixed standard of toluene with a concentration of 100μg / mL, and then take 10mL of toluene solvent into 22mL sample bottle as a blank sample for the whole process; take 10mL of toluene solvent into 22mL sample bottle As a sample absorption bottle; take 10mL toluene solvent into a 22mL sample bottle, and add 20μL mixed standard as the measurement sample, the concentration is 200μg / L; take 20μL mixed standard into 1mL toluene as the measurement standard, the concentr...

example 2

[0094] Test of negative pressure extraction and separation method for PCBs in liquid phase (organic solvent phase, water phase) and solid phase (soil)

[0095] 1. Test method for negative pressure extraction and separation of PCBs with a concentration of 100μg / L in toluene

[0096] (1) Standard solution preparation

[0097] The liquid standard of PCBs was prepared into a toluene phase standard solution with a concentration of 10.0μg / mL.

[0098] Take 10mL of toluene solvent into a 22mL sample bottle as a blank sample throughout the process;

[0099] Take 10mL of toluene solvent into a 22mL sample bottle as a sample absorption bottle;

[0100] Take 10mL of toluene solvent into a 22mL sample bottle, and add 100μL of standard solution as the measurement sample, with a concentration of 100.0μg / L;

[0101] Take 100 μL of the standard solution into 1 mL of toluene as the determination standard, and the concentration is 1 μg / mL.

[0102] (2) Air connection

[0103] The sample heater, the sealed sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com