Preparation method of hydrocarbon steam reforming catalyst

A catalyst and steam technology, which is applied in the field of hydrocarbon steam reforming catalyst preparation, to achieve the effect of reducing carbon deposits, uniform and fine particles, and meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

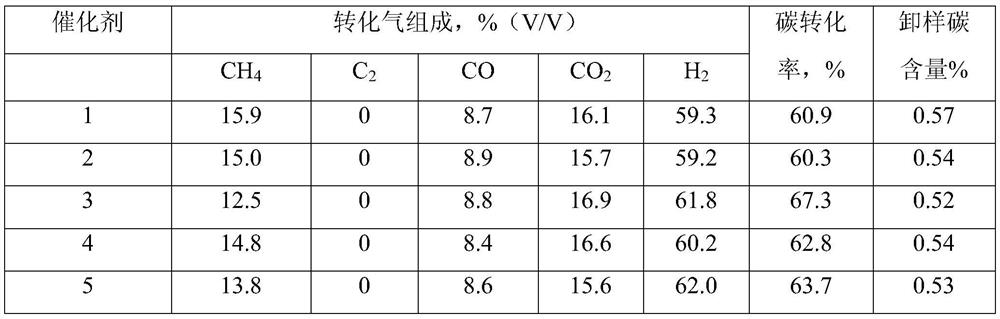

Examples

Embodiment 1

[0026] Weigh 6g of magnesium nitrate and 6.5g of aluminum nitrate, fully mix the two salts, add 44g of urea and grind for 15 minutes, then add 4.66g of nickel nitrate and 1.74g of lanthanum nitrate and grind for 10 minutes, then move the reactant to the In a vinyl fluoride-lined crystallization kettle, react at 178°C for 12 hours to obtain a semi-finished product, add water, graphite and cellulose to shape the semi-finished product, raise the temperature to 450°C at a rate of 2°C / min in the air, and roast at a constant temperature for 2 hours. Then heat up to 750 degrees at a speed of 5° C. / min and roast for 4.5 hours to obtain a finished catalyst.

Embodiment 2

[0028] Weigh 7.4g of magnesium nitrate and 3.76g of aluminum nitrate, fully mix the two salts, add 60g of ammonium bicarbonate and grind for 25 minutes, then add 16.6g of nickel nitrate and 1.3g of cerium nitrate and grind for 20 minutes, then move the reactant to In a polytetrafluoroethylene-lined crystallization kettle, react at 185°C for 24 hours to obtain a semi-finished product, add water, graphite and paraffin to form the semi-finished product, raise the temperature to 400°C at a rate of 5°C / min in the air, and roast at a constant temperature 1.5h, then heating up to 700°C at a rate of 5°C / min and calcining for 3 hours to obtain a finished catalyst.

Embodiment 3

[0030] Weigh 11.84g of magnesium nitrate and 7.5g of aluminum nitrate, fully mix the two salts, add 72g of urea and grind for 35 minutes, then add 13.06g of nickel nitrate and 2g of cerium nitrate and grind for 20 minutes, then move the reactant to the In a vinyl fluoride-lined crystallization kettle, react at 185°C for 24 hours to obtain a semi-finished product, add water and graphite to form the semi-finished product, raise the temperature to 450°C in air at a rate of 3°C / min, and roast at a constant temperature for 1.5h, then Raise the temperature at 5°C / min to 650°C and roast for 4 hours to obtain the finished catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com