PVC (Polyvinyl Chloride) power cable protective sleeve and preparation method thereof

A technology for power cables and sheath tubes, applied in the field of PVC power cable sheath tubes and its preparation, to achieve the effects of ensuring cross-linking effects, improving mechanical properties, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

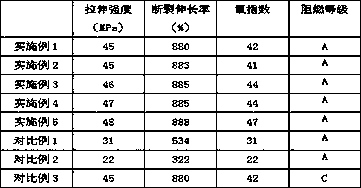

Examples

Embodiment 1

[0037] A kind of preparation method of PVC power cable sheath pipe, concrete steps are as follows:

[0038] (1) Evenly mix light calcium carbonate, silane coupling agent, coated red phosphorus masterbatch, ammonium polyphosphate and decabromodiphenyl ether to obtain the first material and set aside;

[0039] (2) Polyvinyl chloride (PVC), ethylene-vinyl acetate copolymer, styrene-butadiene block copolymer, thermoplastic polyester elastomer (TPEE) and polyarylether nitrile-polysiloxane block copolymerization Add the material into a high-speed mixer, stir at a low speed, add trioctyl trimellitate and di-sec-octyl phthalate, stir at a high speed, melt and blend at 70°C for 10 minutes, then add the first material obtained in step (1), and continue Stir at high speed to 90°C, and crosslink for 20 minutes at this temperature;

[0040] (3) Add alginate, lubricant and antistatic agent, and continue stirring at high speed for 10 minutes to obtain a mixture;

[0041] (4) adding the mix...

Embodiment 2

[0050] A kind of preparation method of PVC power cable sheath pipe, concrete steps are as follows:

[0051] (1) Evenly mix light calcium carbonate, silane coupling agent, coated red phosphorus masterbatch, ammonium polyphosphate and decabromodiphenyl ether to obtain the first material and set aside;

[0052] (2) Polyvinyl chloride (PVC), ethylene-vinyl acetate copolymer, styrene-butadiene block copolymer, thermoplastic polyester elastomer (TPEE) and polyarylether nitrile-polysiloxane block copolymerization Add the material into a high-speed mixer, stir at a low speed, add trioctyl trimellitate and di-sec-octyl phthalate, stir at a high speed, melt and blend at 75°C for 15 minutes, then add the first material obtained in step (1), and continue Stir at high speed to 95°C, and crosslink for 25 minutes at this temperature;

[0053] (3) Add alginate, lubricant and antistatic agent, and continue stirring at high speed for 12 minutes to obtain a mixture;

[0054] (4) adding the mix...

Embodiment 3

[0063] A kind of preparation method of PVC power cable sheath pipe, concrete steps are as follows:

[0064] (1) Evenly mix light calcium carbonate, silane coupling agent, coated red phosphorus masterbatch, ammonium polyphosphate and decabromodiphenyl ether to obtain the first material and set aside;

[0065] (2) Polyvinyl chloride (PVC), ethylene-vinyl acetate copolymer, styrene-butadiene block copolymer, thermoplastic polyester elastomer (TPEE) and polyarylether nitrile-polysiloxane block copolymerization Add the material into a high-speed mixer, stir at a low speed, add trioctyl trimellitate and di-sec-octyl phthalate, stir at a high speed, melt and blend at 70°C for 15 minutes, then add the first material obtained in step (1), and continue Stir at high speed to 90°C, and crosslink for 25 minutes at this temperature;

[0066] (3) Add alginate, lubricant and antistatic agent, and continue stirring at high speed for 10 minutes to obtain a mixture;

[0067] (4) adding the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com