Method for enhancing efficacy of enzyme using lactobacillus bulgaricus

A technology of subsp. bulgaricus and Lactobacillus, applied in the field of fermented food, can solve the problems of poor taste or flavor, easy to contaminate miscellaneous bacteria, long fermentation period, etc., and achieve the effect of improving the antibacterial ability of enzymes and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation of enzyme raw materials: wash dragon fruit, apple, tomato and soybean with hot water, put them on a clean workbench to air dry, cut into small pieces; weigh 100g of each fruit and vegetable, mix them evenly, and put them into a fermentation container , adding glucose with a mass percentage of 15% of the fruit and vegetable raw material, and then adding water with a mass percentage of 100% of the fruit and vegetable raw material, and fully stirring evenly.

[0045] 2. Inoculation strain:

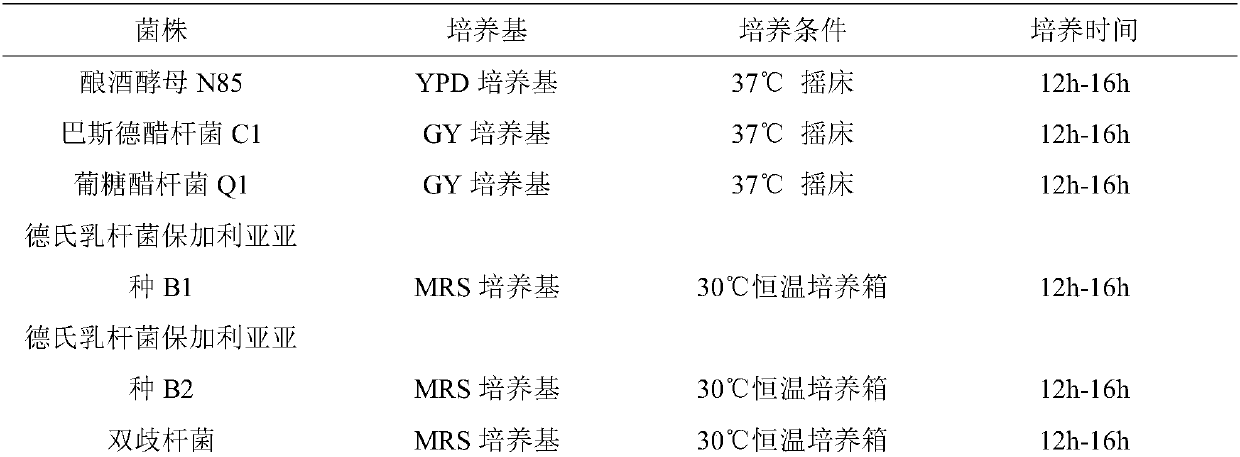

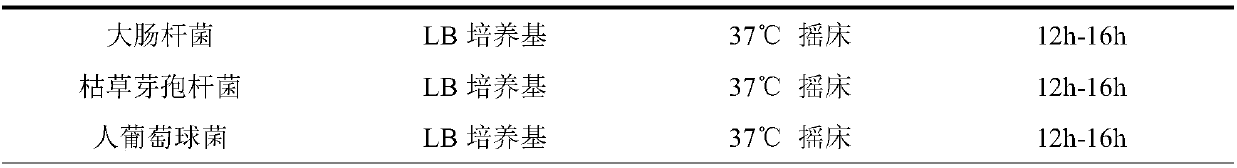

[0046] Activated strains: Saccharomyces cerevisiae N85 and Gluconacetobacter Q1 were taken out from the -80°C refrigerator, and streaked and inoculated in the corresponding culture medium respectively.

[0047] Obtain bacteria: Pick a single colony on the solid medium and inoculate it into the liquid medium, culture it to the logarithmic growth phase, centrifuge at 10000rpm for 10min, discard the supernatant, and use sterile normal saline with normal saline: bacterial so...

Embodiment 2

[0051] 1. Preparation of enzyme raw materials: wash dragon fruit, apple, tomato and soybean with hot water, put them on a clean workbench to air dry, cut into small pieces; weigh 100g of each fruit and vegetable, mix them evenly, and put them into a fermentation container , adding glucose with a mass percentage of 15% of the fruit and vegetable raw material, and then adding water with a mass percentage of 100% of the fruit and vegetable raw material, and fully stirring evenly.

[0052] 2. Inoculation strain:

[0053] Activated strains: Saccharomyces cerevisiae N85 and Lactobacillus delbrueckii subsp. bulgaricus B1 were taken out from the -80°C refrigerator and streaked into the corresponding medium.

[0054] Obtain bacteria: Pick a single colony on the solid medium and inoculate it into the liquid medium, culture it to the logarithmic growth phase, centrifuge at 10000rpm for 10min, discard the supernatant, and use sterile normal saline with normal saline: bacterial solution 1:...

Embodiment 3

[0058] 1. Preparation of enzyme raw materials: wash dragon fruit, apple, tomato and soybean with hot water, put them on a clean workbench to air dry, cut into small pieces; weigh 100g of each fruit and vegetable, mix them evenly, and put them into a fermentation container , adding glucose with a mass percentage of 15% of the fruit and vegetable raw material, and then adding water with a mass percentage of 100% of the fruit and vegetable raw material, and fully stirring evenly.

[0059] 2. Inoculation strain:

[0060] Activated strains: Saccharomyces cerevisiae N85 and Lactobacillus delbrueckii subsp. bulgaricus B2 were taken out from the -80°C refrigerator and inoculated in the corresponding medium by streaking.

[0061] Obtain bacteria: Pick a single colony on the solid medium and inoculate it into the liquid medium, culture it to the logarithmic growth phase, centrifuge at 10000rpm for 10min, discard the supernatant, and use sterile normal saline with normal saline: bacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com